Gradient coercive-force neodymium-ferrum-boron magnet and production method thereof

A production method and coercive force technology, applied in the direction of magnets, magnetic objects, magnetic materials, etc., can solve the problems of the decrease of the magnetic energy product of the magnet, the decrease of the motor output, and the increase of the magnet, so as to reduce the thermal demagnetization, improve the overall remanence, Resistant to high temperature and reverse magnetic fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

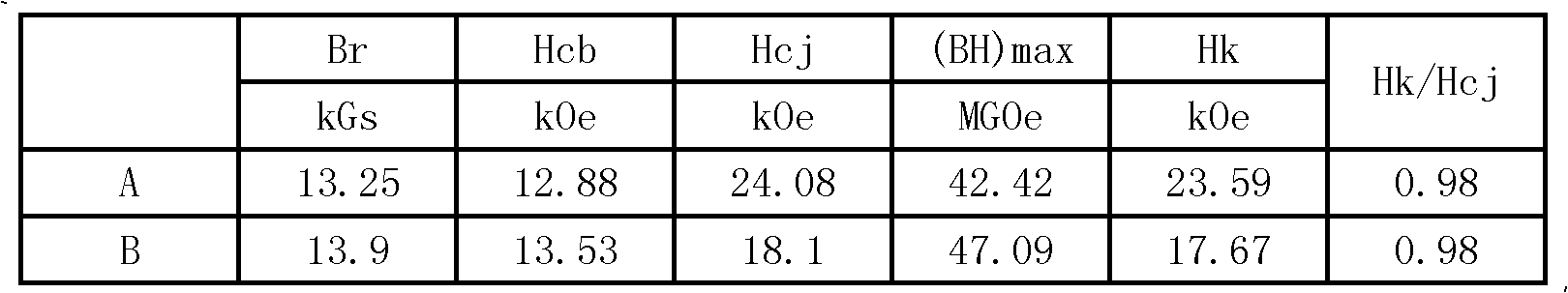

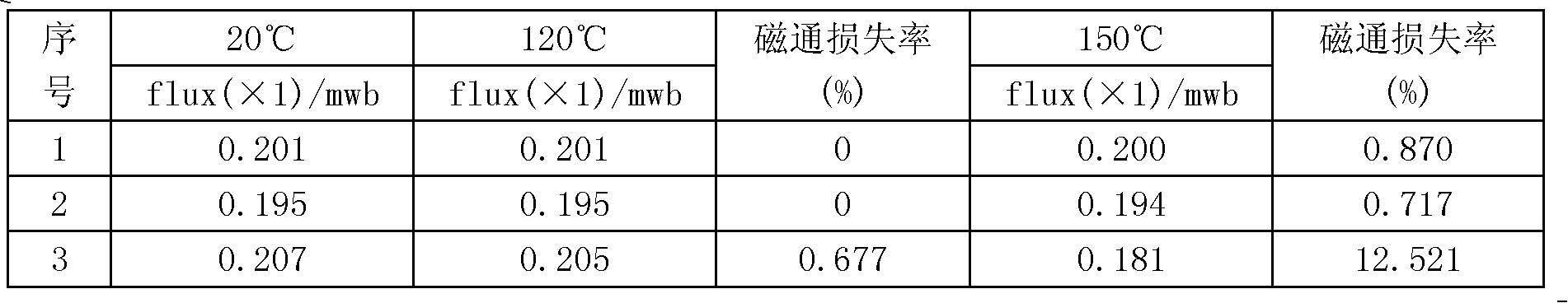

[0025] 48H-42SH gradient coercivity NdFeB magnets:

[0026] Change the recipe to Nd 20 PR 5.5 Dy 4.5 co 2 Cu 0.15 Ga 0.1 al 0.2 B 1 Nb 0.1 Fe 余量 The raw material is smelted into alloy A in a vacuum strip continuous casting furnace, and the formula is Nd 21 PR 6 Dy 2.5 co 1 Cu 0.1 Ga 0.1 B 1 Nb 0.1 Fe 余量 The raw materials are smelted into alloy B in the vacuum strip continuous casting furnace, and the alloy sheets A and B are respectively put into the hydrogen treatment furnace for hydrogen crushing. After the hydrogen crushing, the N 2 In an oxygen-free environment under the protection of gas, the powder is finely pulverized by jet mill to obtain a powder particle size of 3.6 μm;

[0027] Molded in the vertical magnetic orientation forming device of the atmosphere with an oxygen content of less than 1%; in the mold cavity with a length of 72mm and an orientation direction of 22mm, a copper separator with a length of 71.9mm, a height of 105mm, and a thickness ...

Embodiment 2

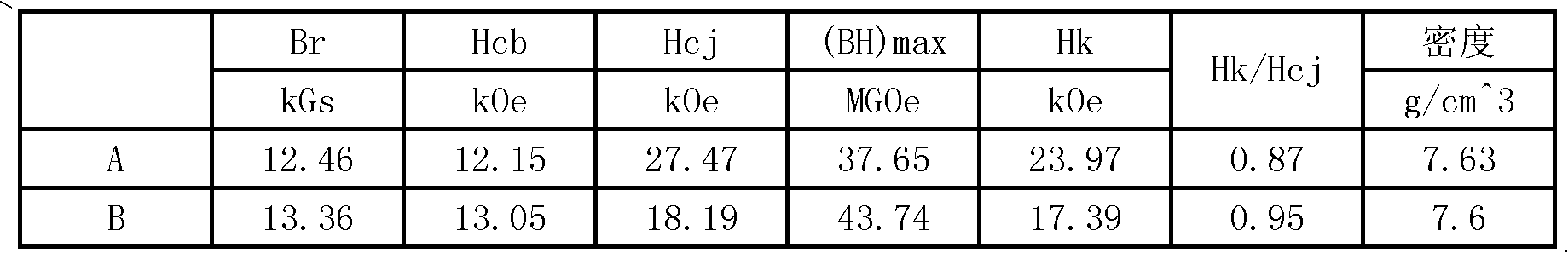

[0036] 44H-38UH gradient coercivity NdFeB magnet:

[0037] Change the recipe to Nd 20 PR 5.2 Dy 6 co 1 Cu 0.1 Ga 0.15 B 0.97 Nb 0.1 Fe 余量 The raw material is smelted into alloy A in a vacuum strip continuous casting furnace, and the formula is Nd 24.8 PR 4.5 Dy2.4 co 0.8 Cu 0.1 Ga 0.1 al 0.15 B 0.95 Nb 0.1 Fe 余量 The raw materials are smelted into alloy B in the vacuum strip continuous casting furnace, and the alloy sheets A and B are respectively put into the hydrogen treatment furnace for hydrogen crushing. After the hydrogen crushing, the N 2 In an oxygen-free environment under the protection of gas, it is finely pulverized by a jet mill to obtain a powder particle size of 3.5 μm; it is formed in a parallel magnetic orientation molding device in an atmosphere with an oxygen content of less than 1%, and the length direction is 75 mm, and the width direction is 50 mm. The mold cavity is first filled with powder of alloy A to a height of 5.5mm, and then filled ...

Embodiment 3

[0046] 42SH-48H-42SH gradient coercivity NdFeB magnets:

[0047] Change the recipe to Nd 20 PR 5.5 Dy 4.5 co 2 Cu 0.15 Ga 0.1 al 0.2 B 1 Nb 0.1 Fe 余量 The raw material is smelted into alloy A in a vacuum strip continuous casting furnace, and the formula is Nd 21 PR 6 Dy 2.5 co 1 Cu 0.1 Ga 0.1 B 1 Nb 0.1 Fe 余量 The raw materials are smelted into alloy B in the vacuum strip continuous casting furnace, and the alloy sheets A and B are respectively put into the hydrogen treatment furnace for hydrogen crushing. After the hydrogen crushing, the N 2 In an oxygen-free environment under the protection of gas, the powder is finely pulverized by jet mill to obtain a powder particle size of 3.6 μm;

[0048] Molded in a vertical magnetic orientation molding device with an atmosphere with an oxygen content of less than 1%; a copper separator 2 with a length of 71.9 mm, a height of 105 mm, and a thickness of 0.5 mm is placed in a cavity with a length of 72 mm and an orientati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com