Efficient direct connection type air compressor oil-cooling permanent magnet synchronous motor and pouring process thereof

A permanent magnet synchronous motor, air compressor oil technology, applied in synchronous motors with static armatures and rotating magnets, electromechanical devices, electric components, etc. Low problems, to achieve the effect of improving waterproof and moisture-proof ability, strengthening integrity, and efficient cooling scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

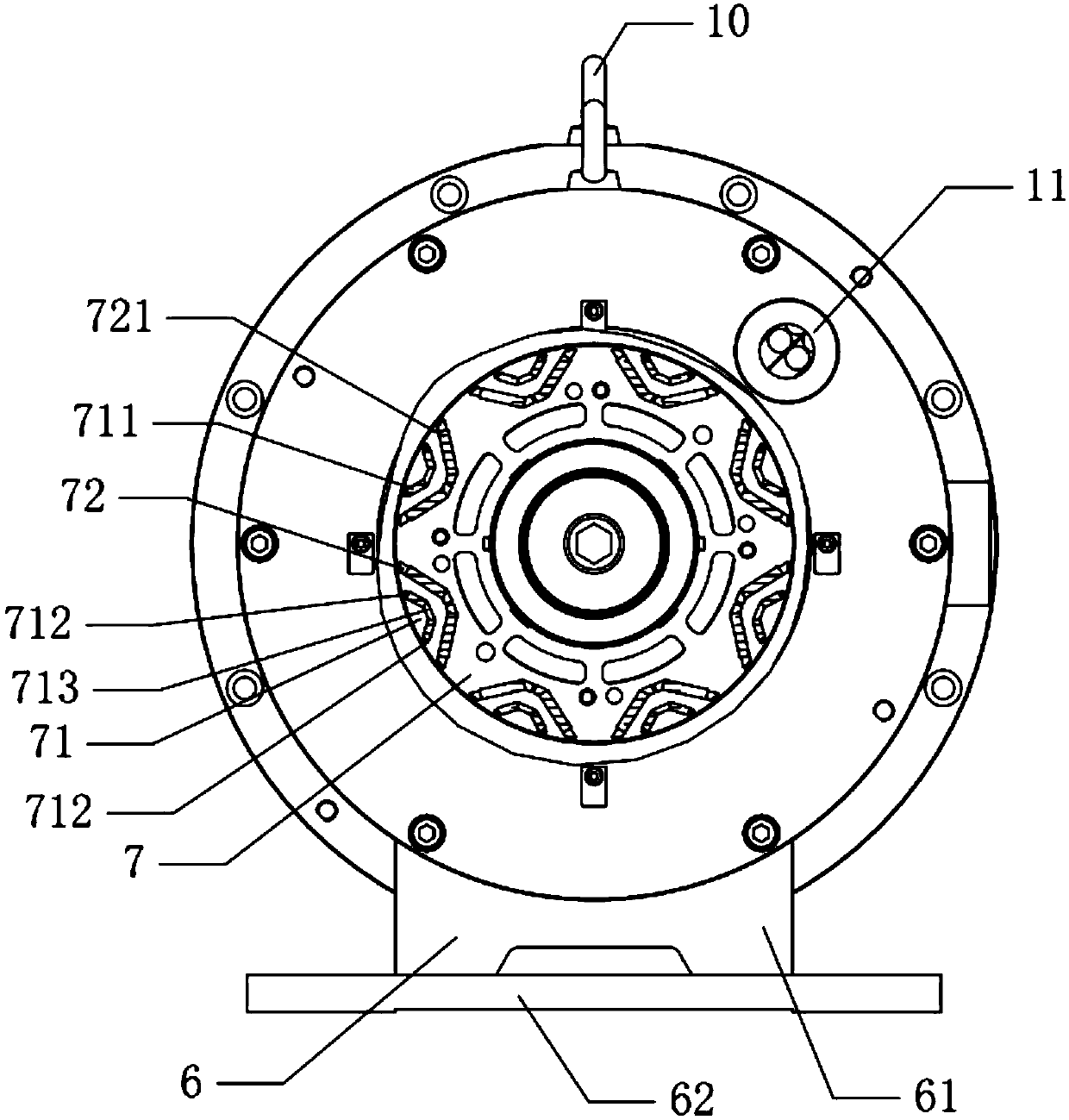

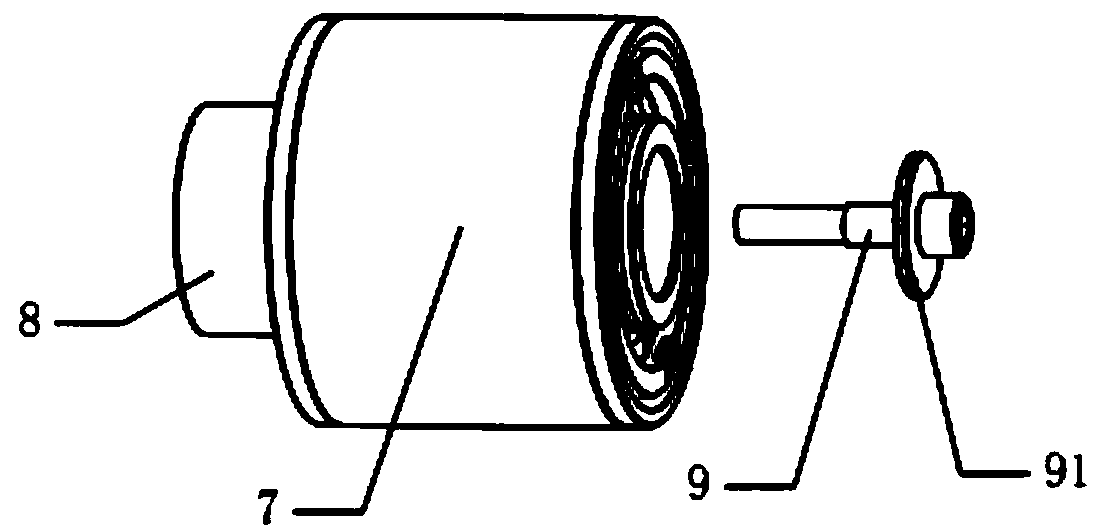

[0035] like figure 1 , 4 The high-efficiency direct-connected air compressor oil-cooled permanent magnet synchronous motor and its filling process shown include front flange 1, motor casing 2, stator core 3, wire package 4, rear flange 5, base 6, rotor iron Core 7, rotating shaft 8 and rotor locking screw 9, the front flange 1 is connected to the left end of the motor casing 2, the rear flange 5 is connected to the right end of the motor casing 2, the stator core 3, wire The package 4, the rotor core 7, the rotating shaft 8 and the rotor locking screw 9 are all arranged inside the motor casing 2, the wire package 4 is wound on the stator core 3, and the wire package 4 is evenly arranged along the circumference of the stator core 3, The rotor core 7 is sleeved in the stator core 3, the rotating shaft 8 is disposed in the rotor core 7, and the stator core 3, the rotor core 7 and the rotating shaft 8 are concentric structures; wherein, as image 3 The rotor locking screw 9 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com