Device and method for automatically detecting incident angle in elliptical polarization measuring system

A technology of incident angle and measurement system, applied in the field of optical measurement, can solve the problems of low cost, inability to record automatically by equipment, low efficiency, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

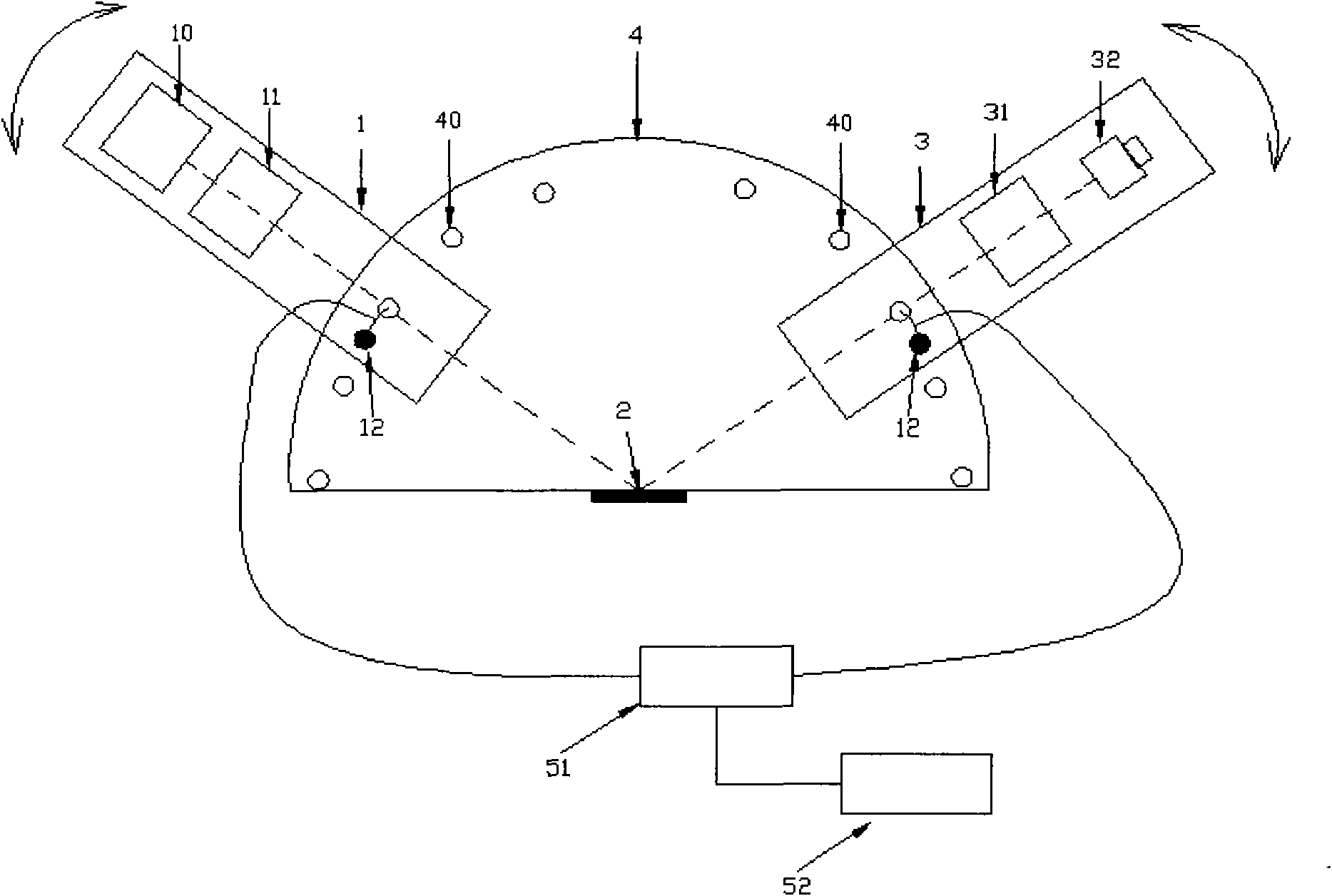

[0056] Such as figure 1 As shown, the schematic diagram shows a device for automatic detection of incident angle in an ellipsometry system (basic structure: polarizing arm, sample, analyzer arm, and substrate).

[0057] The structure of the system is as follows: a position detection switch 40 is installed on the substrate 4, a trigger device 12 is installed on the polarizing arm 1, and a trigger device 12 is also installed on the analyzer arm 3. When the deflection arm 1 and the analyzer arm 3 rotate to a certain angle, the trigger device 12 triggers the position detection switch 40 at that position, and the left and right sides output signals respectively. In order to determine whether the angle values on both sides are consistent, the position detection switch 40 is electrically connected to the signal processing unit 51, and the signal processing unit 51 judges and processes the signal output by the position detection switch 40. The signal processing unit 51 is electrically ...

Embodiment 2

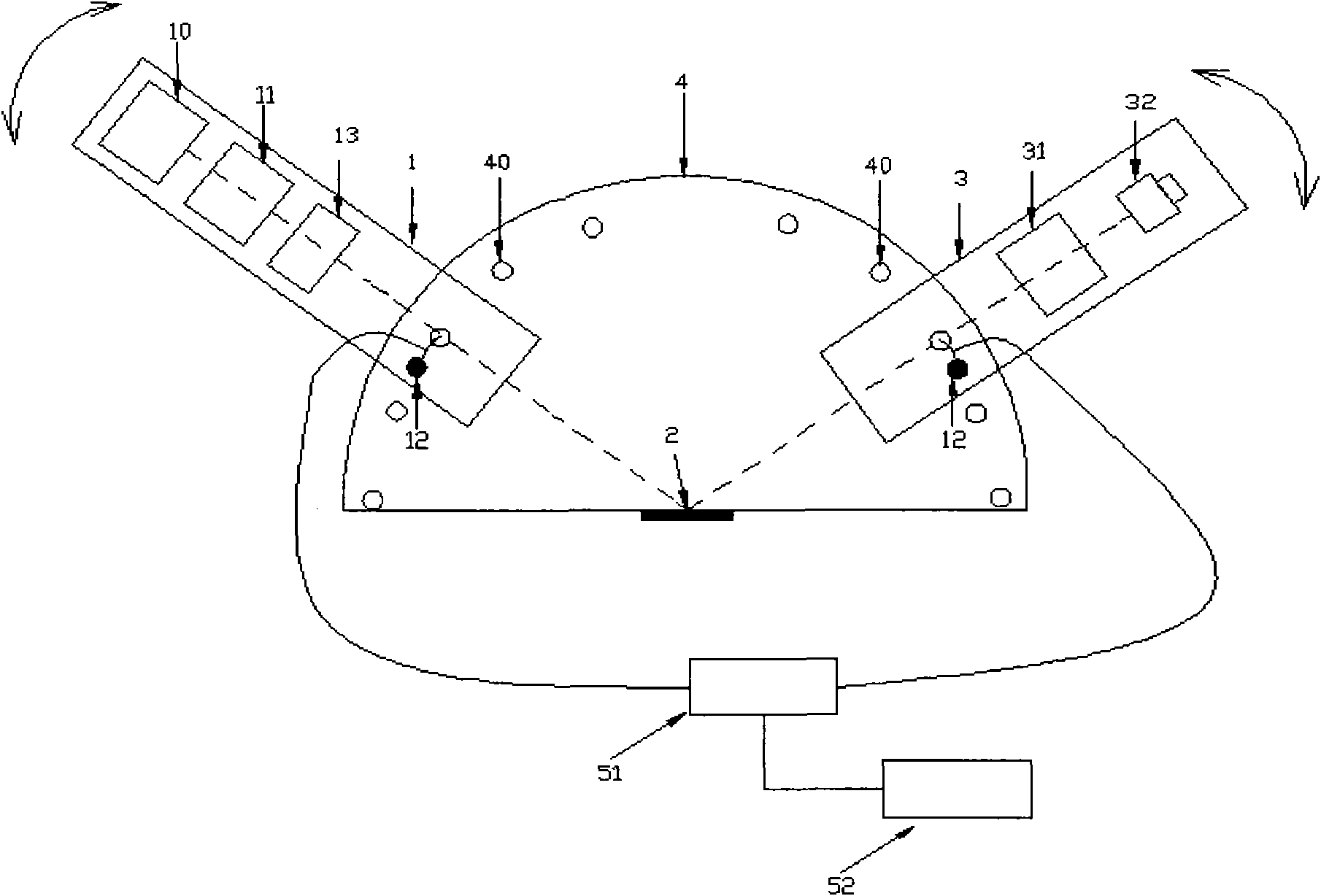

[0066] Such as figure 2 As shown, the schematic diagram shows a device for automatic detection of the incident angle in an ellipsometry system (basic structure: polarizing arm, sample, analyzer arm, and substrate).

[0067] In the above device, compared with the first embodiment, the difference is that the phase compensator 13 is installed between the linear polarizer 11 on the polarizing arm 1 and the sample 2, and the rest is the same as the device in the first embodiment.

[0068] In the above device, the phase compensator 13 can be a 1 / 4 glass slide or a glass slide with any phase retardation, which has two directions of fast axis and slow axis perpendicular to each other in a plane perpendicular to the propagation direction of light waves. , The phase delay difference of light waves in the two directions is different. The glass slide can be a mica glass slide, a liquid crystal with phase retardation, a quartz glass slide, a thin film glass slide, a total reflection type phase...

Embodiment 3

[0071] Such as image 3 As shown, the schematic diagram shows a device for automatic detection of the incident angle in an ellipsometry system (basic structure: polarizing arm, sample, analyzer arm, and substrate).

[0072] In the above device, except that the phase compensator 13 is installed between the linear polarizer 11 on the analyzer arm 3 and the sample 2, the other is the same as the device in Example 2.

[0073] In the above device, when the incident angle in the ellipsometry device needs to be automatically detected, the same method steps as in the second embodiment are used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com