Thermoset hybrid fabric composite material and preparation method and application thereof

A composite material, thermosetting technology, used in transportation and packaging, superstructure sub-assembly, superstructure and other directions, can solve the problems of high temperature resistance, low compressive strength, poor surface bonding performance, etc., to reduce vehicle weight, improve Toughness, the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. The raw materials and their volume percentages listed in the following table are used to prepare thermosetting hybrid fabric composite materials for automobile engine covers:

[0036]

content

Carbon fiber (specification 6k, provided by Shanxi Institute of Coal Chemistry, Chinese Academy of Sciences)

37%

UHMWPE fiber (Hunan Zhongtai Special Equipment Co., Ltd.)

32%

Novolac epoxy vinyl ester resin (Shangwei (Shanghai) Fine Chemical Co., Ltd.)

28%

Curing agent: cyclohexanone peroxide

0.9%

Accelerator: cobalt naphthenate

0.6%

Release agent: fatty acid (19SAM, Beijing Kekelas Chemical Technology Co., Ltd.)

1.5%

[0037] 2. Preparation process

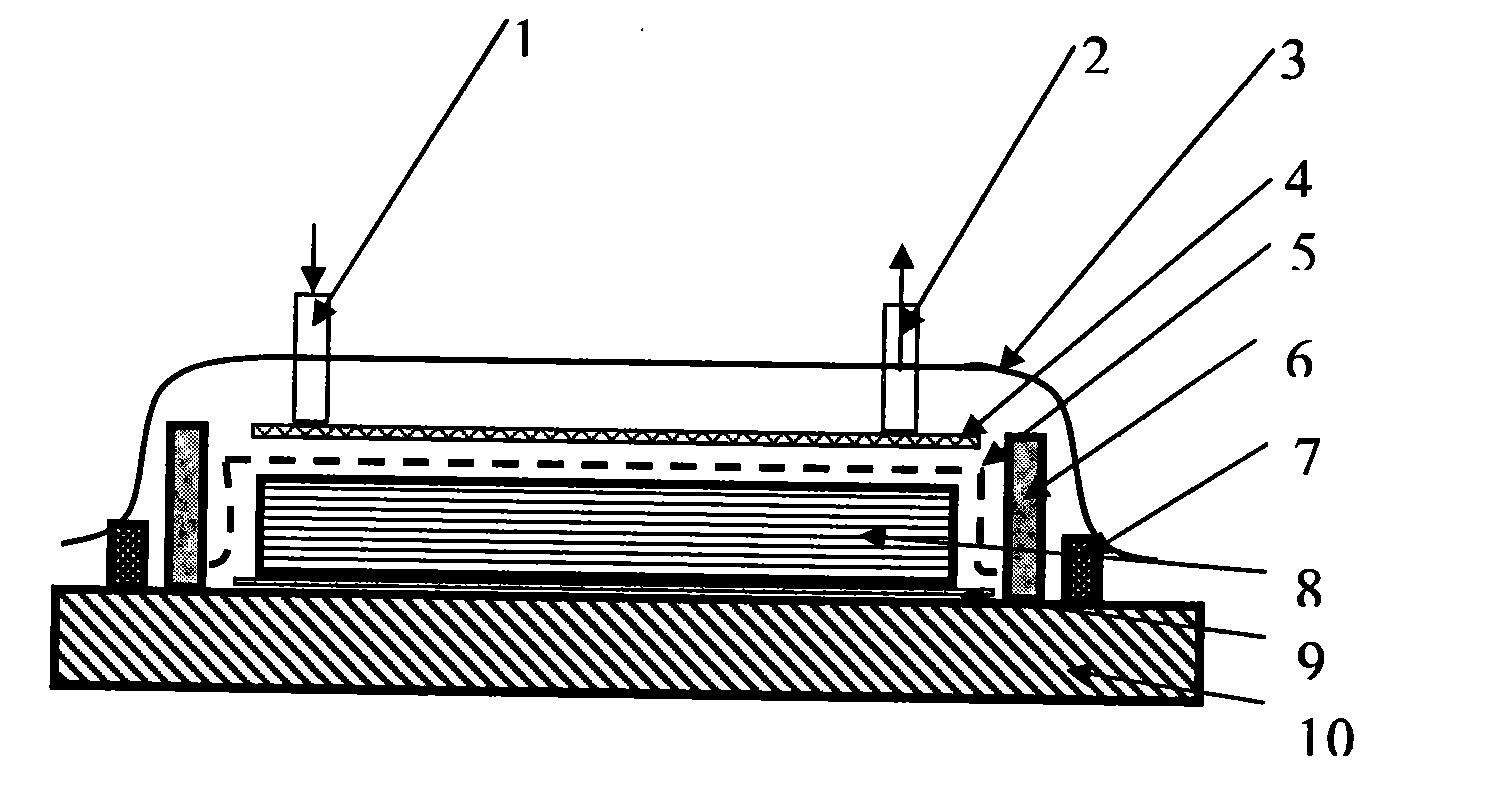

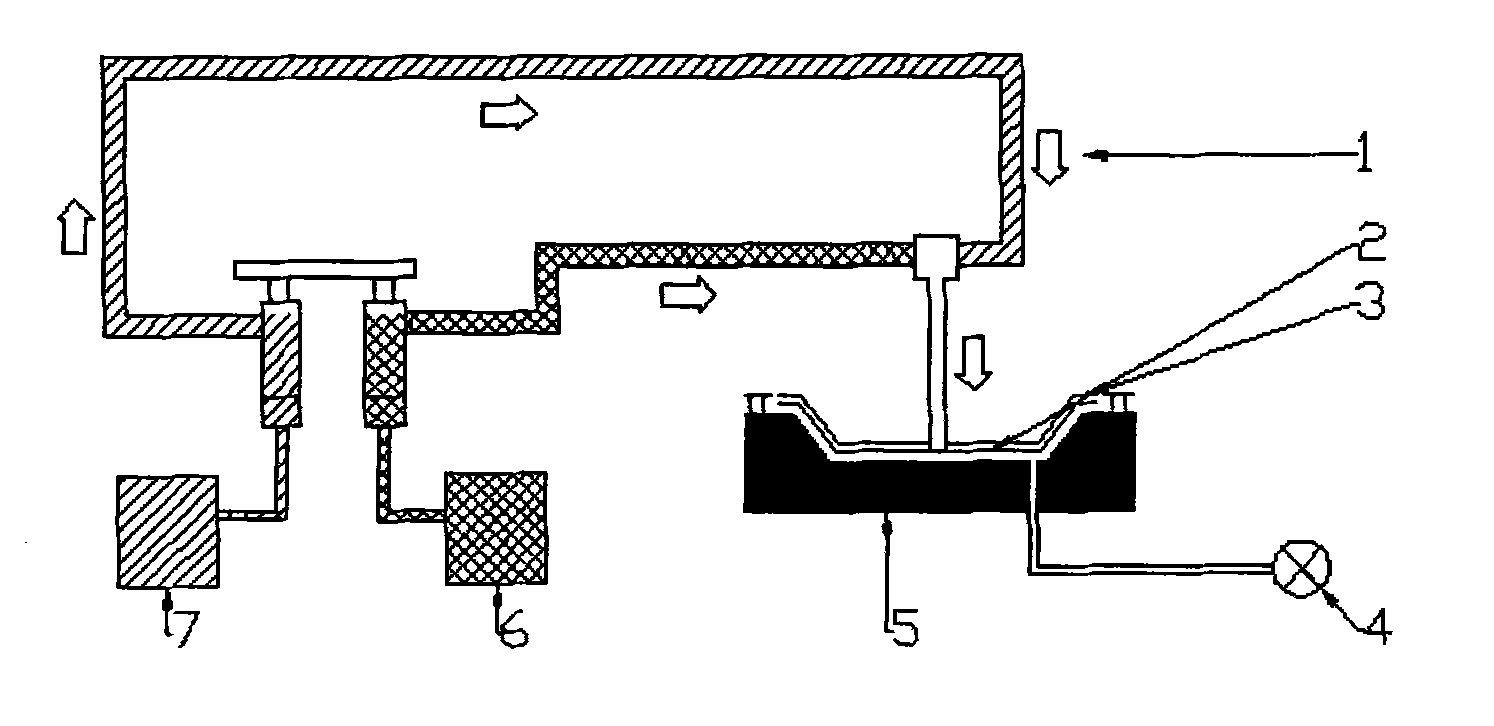

[0038] Weave carbon fiber and UHMWPE fiber into three twill patterns using existing weaving technology figure 1 The carbon fiber and UHMWPE fiber hybrid fabric shown is cut into a fabric with a si...

Embodiment 2

[0046] Except that the raw materials were replaced according to the above table, the rest of the operations were the same as in Example 1 to obtain a thermosetting hybrid fabric composite material for the automobile engine cover.

[0047] The above-mentioned thermosetting hybrid fabric composite material for the automobile engine cover was tested under a universal testing machine. The results of multiple experiments showed that the elastic modulus of the composite material was close to 46GPa, the tensile strength was 452MPa, and the ultimate strain reached 2.7 %. According to ASTM256-03 test material impact performance, the impact strength of the composite material is 32.5kJ / m when the ambient temperature is (24±1)°C and the relative humidity is (52±10)%. 2 . The surface quality of this material reaches grade A, the dimensional accuracy is 0.5 grade, and the production cycle is 1 hour.

[0048] Compared with ordinary carbon fiber reinforced composite materials, the hy...

Embodiment 3

[0051] Except that the raw materials were replaced according to the above table, the rest of the operations were the same as in Example 1 to obtain a thermosetting hybrid fabric composite material for the automobile engine cover.

[0052] The above-mentioned thermosetting hybrid fabric composite material for the automobile engine cover was tested under a universal testing machine. The results of multiple experiments showed that the elastic modulus of the composite material was close to 48GPa, the tensile strength was 460MPa, and the ultimate strain reached 2.7 %. According to ASTM256-03 test material impact performance, the impact strength of the composite material is 34.5kJ / m when the ambient temperature is (20±6)°C and the relative humidity is (50±15)%. 2 . The surface quality of this material reaches grade A, the dimensional accuracy is 0.5 grade, and the production cycle is 1 hour.

[0053] Compared with ordinary carbon fiber reinforced composite materials, the hybrid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com