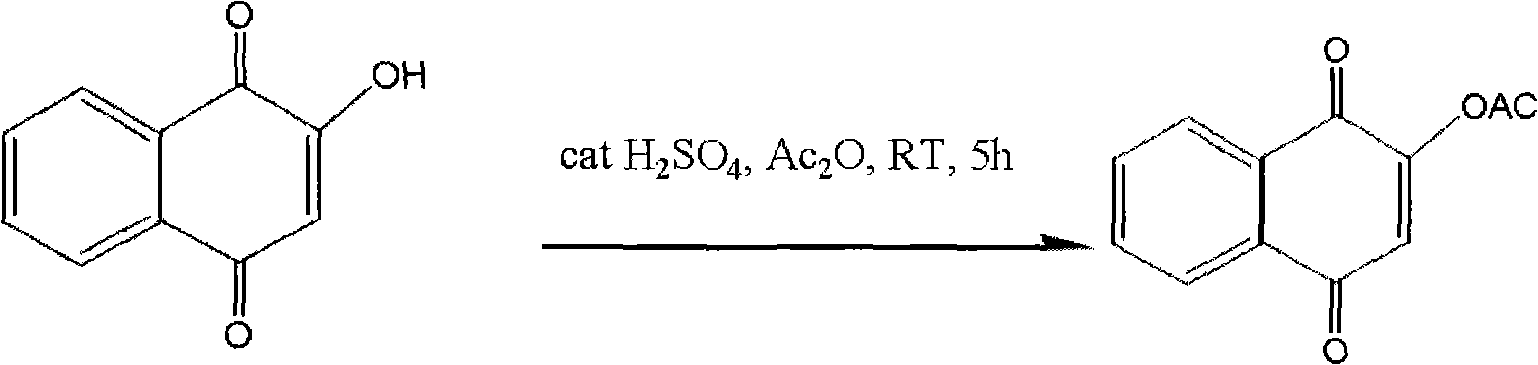

Preparation method of 2-acetoxyl-1,4-naphthoquinone

A technology of acetoxyl and naphthoquinone, applied in the field of preparation of naphthoquinone, can solve problems such as rare chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 7g of 2-hydroxy-1,4-naphthoquinone to 100mL of acetic anhydride; heat it in a water bath to 55°C and add concentrated sulfuric acid; react for 3 hours and cool the reactant to room temperature; add the reaction solution to 300mL of ice water and filter it to obtain 5.0 g of crude 2-acetoxy-1,4-naphthoquinone; add the crude product into 100 mL of ethyl acetate, heat until the solid dissolves, cool to room temperature, and filter with suction. The resulting product was baked in an oven at 50°C for 12 hours to dryness to obtain 4.5 g of the product with a yield of 80%, m.p.129°C.

Embodiment 2

[0019] Add 15g of 2-hydroxy-1,4-naphthoquinone to 200mL of acetic anhydride; heat it in a water bath to 55°C and add concentrated sulfuric acid; react for 5 hours and cool the reactant to room temperature; add the reaction solution to 300mL of ice water and filter it with suction to obtain 8.0 g of crude 2-acetoxy-1,4-naphthoquinone; add the crude product into 100 mL of ethyl acetate, heat until the solid dissolves, cool to room temperature, and filter with suction. The resulting product was baked in an oven at 50°C for 12 hours to dryness to obtain 7.2 g of the product with a yield of 72%, m.p.129°C.

Embodiment 3

[0021] Add 7g of 2-hydroxy-1,4-naphthoquinone to 100mL of acetic anhydride; heat in a water bath to 70°C and add concentrated sulfuric acid; react for 3 hours and cool the reactant to room temperature; add the reaction solution to 300mL of ice water and filter it to obtain 4.8g 2-acetoxy-1,4-naphthoquinone crude product; add the crude product into 100mL ethyl acetate, heat until the solid dissolves, cool to room temperature, and filter with suction. The obtained product was baked in an oven at 50°C for 12 hours until dry to obtain 4.0 g of the product with a yield of 81%, m.p.129°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com