Clodinafop-propargyl aqueous emulsion and preparation method thereof

A technology of clodopagyl and water emulsion, which is applied in botany equipment and methods, herbicides, algicides, biocides, etc., can solve the problems of high cost, environmental pollution, and low safety in use, and achieve the elimination of system foam, Eliminate dust pollution, facilitate processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

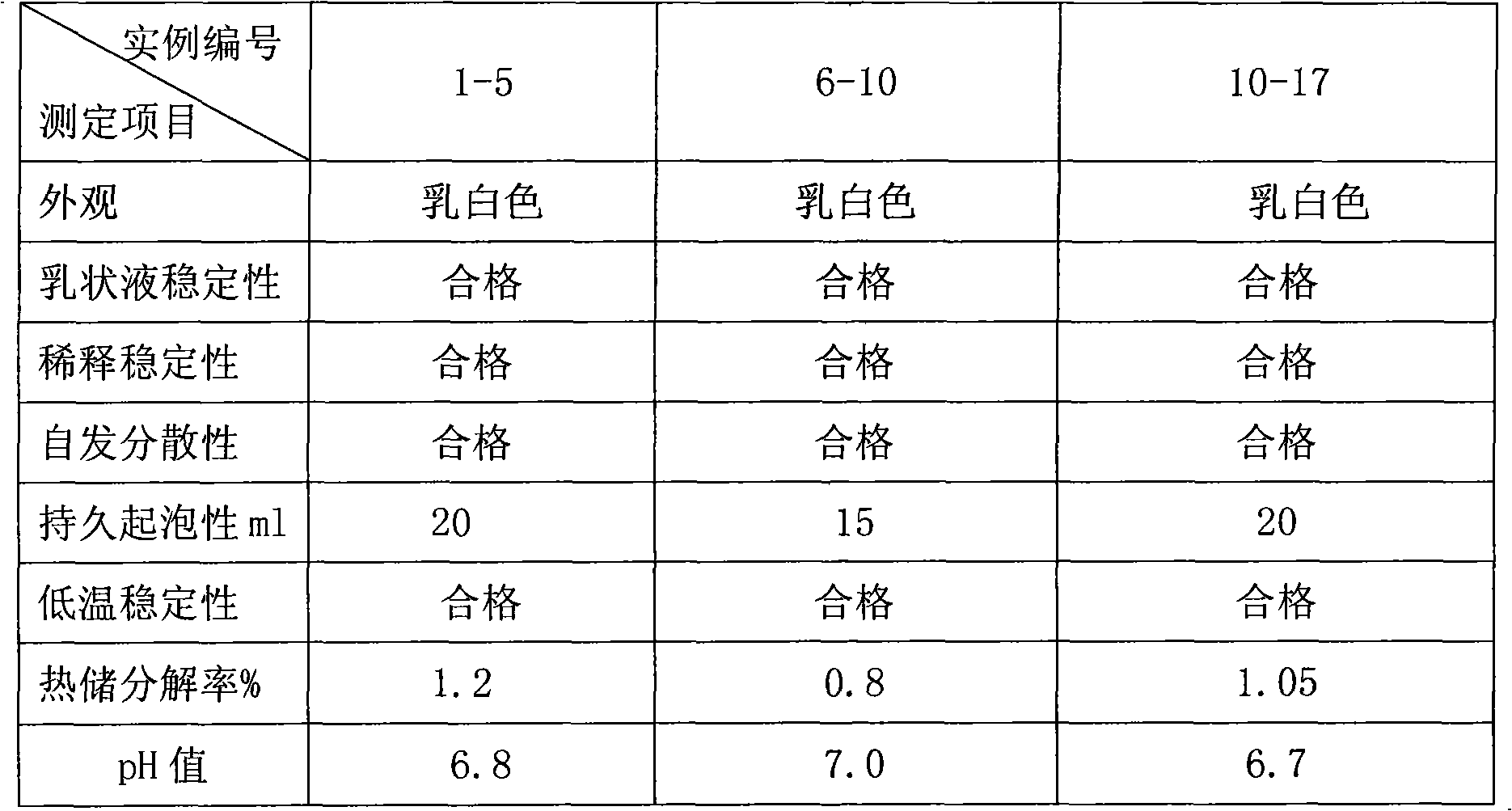

Examples

Embodiment 1

[0013] 105g of clodinafop-argyl prodrugate with a purity of 95% was dissolved in 230 mixed benzene, stirred until transparent with a machine, and 20g of calcium dodecylbenzenesulfonate, 30g of fatty alcohol polyoxyethylene ether phosphate (AEO9-P), Trisiloxane 100g, ammonia water 10g, ethylene glycol 50g, xanthan gum 5g, defoamer polyether modified polysiloxane 1.0g, lactic acid 1.0g, the above-mentioned mixed material is slowly mixed under the condition of high-shear emulsifier Add 449g of water, the rotating speed of the high-shear emulsifier is 1500 revs / min, and the shearing time is 10 minutes to obtain the milky white oxaloprexate aqueous emulsion product.

Embodiment 2

[0015] Dissolve 105g of clodopradylglycerin with a purity of 95% in 220g of toluene, stir until transparent, then add 40g of sorbitan fatty acid ester, styrylphenol formaldehyde resin, polyoxyethylene-polyoxypropylene block polyether (Nongru No. 33) 20g, fatty alcohol polyoxyethylene ether phosphate (AEO9-P) 30g, trisiloxane 50g, diethanolamine 10g, propylene glycol 50g, carboxymethylcellulose sodium (CMC-Na) 3g, poly Ether-modified polysiloxane 1.0g, slowly add 471g of water to above-mentioned mixed material under the condition of high-shear emulsifier, the rotating speed of high-shear emulsifier is 3000 rev / min, and shearing time is 15 minutes, both obtained milky white alkyne Oxalic acid water emulsion product.

Embodiment 3

[0017] Dissolve 105g of clodoparylglycerin with a purity of 95% in 100g of toluene and 100g of cyclohexanone, stir it mechanically until it becomes transparent, then add 30g of calcium dodecylbenzenesulfonate, alkylphenol polyoxyethylene ether phosphate ethanolamine salt 30g, fatty alcohol polyoxyethylene ether (AEO9) 30g, trisiloxane 20g, citric acid 5g, glycerin 30g, carboxymethylcellulose (CMC) 1g, polyether modified polysiloxane 1.0g, will The above mixed material was slowly added with 543 g of water under the condition of a high-shear emulsifier, the rotating speed of the high-shear emulsifier was 4000 rpm, and the shearing time was 20 minutes, to obtain a milky white clodopradyl water emulsion product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com