A kind of compound oil displacement agent for high salinity reservoir

A high-salinity, composite flooding technology, which is applied in the direction of drilling compositions, chemical instruments and methods, and production fluids, can solve the problems of low temperature and salt resistance, increase the sweep coefficient, and protect the environment Benefits and economic benefits, effects in favor of control and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

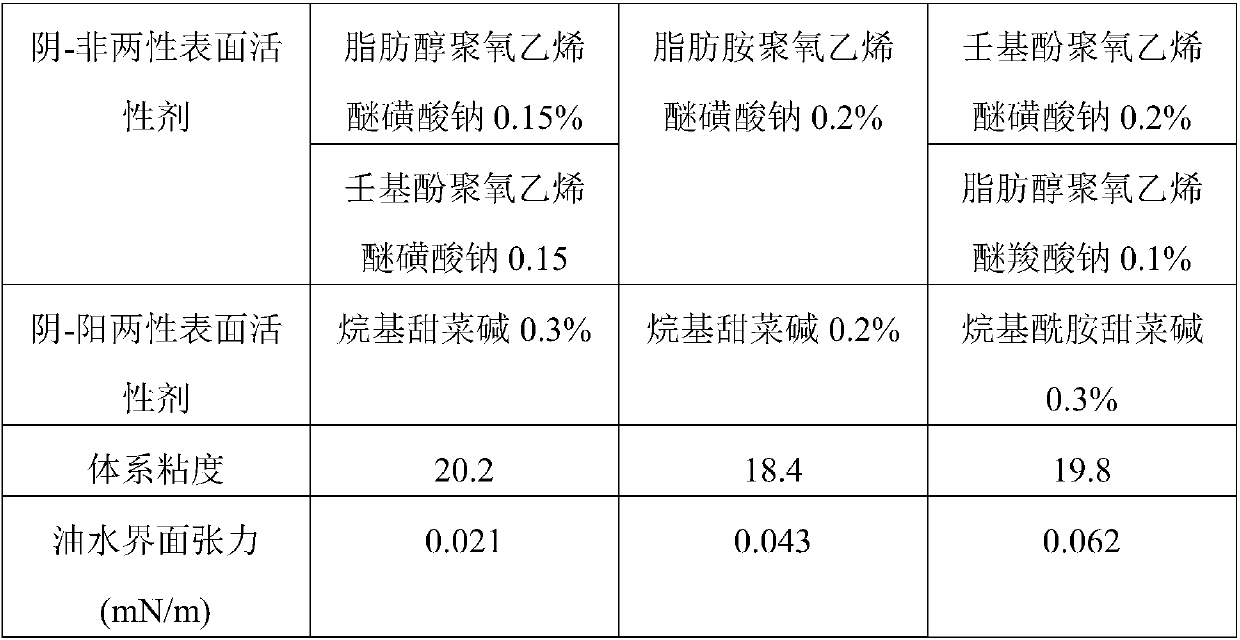

[0025] Example 1 Composite oil displacement agent for high salinity reservoirs at a temperature of 55°C

[0026] Total salinity 100000mg / L, Ca 2+ , Mg 2+ More than 2000mg / L formation water: 99.4%, biopolymer xanthan gum: 0.1%, fatty alcohol polyoxyethylene ether sodium sulfate: 0.5%, stir with a stirrer at high speed for 10 minutes to obtain a uniform and transparent composite oil displacement agent . At the same time, after sealing in a 50ml ampule bottle, observe the long-term thermal stability experiment in a 55°C water bath for 6 months, and measure the apparent viscosity and interfacial tension of the solution.

[0027] The apparent viscosity was measured by a BROODFIELD II viscometer from Brookfield Corporation of the United States at a speed of 6 rpm. The interfacial tension was measured by a TX500 spinning drop interfacial tensiometer produced by the University of Texas, and the crude oil sample was crude oil from the Baiyinchagan Dalqi Oilfield in Inner Mongolia. ...

Embodiment 2

[0030] Example 2 Composite oil displacement agent for high salinity reservoirs at a temperature of 85°C

[0031] Total salinity 200000mg / L, Ca 2+ , Mg 2+ More than 4000mg / L formation water: 99.4%, xanthan gum: 0.1%, sodium fatty alcohol polyoxyethylene ether sulfonate: 0.5%, stir with a stirrer at high speed for 10 minutes to obtain a uniform and transparent composite oil displacement agent. At the same time, after sealing in a 50ml ampule bottle, observe the long-term thermal stability experiment for 6 months at a constant temperature in a water bath at 85°C, and measure the apparent viscosity and interfacial tension of the solution.

[0032] The apparent viscosity was measured by a BROODFIELD II viscometer from Brookfield Corporation of the United States at a speed of 6 rpm. The interfacial tension was measured by a TX500 spinning drop interfacial tensiometer produced by the University of Texas in the United States, and the crude oil sample was crude oil from Shaer Shang, ...

Embodiment 3

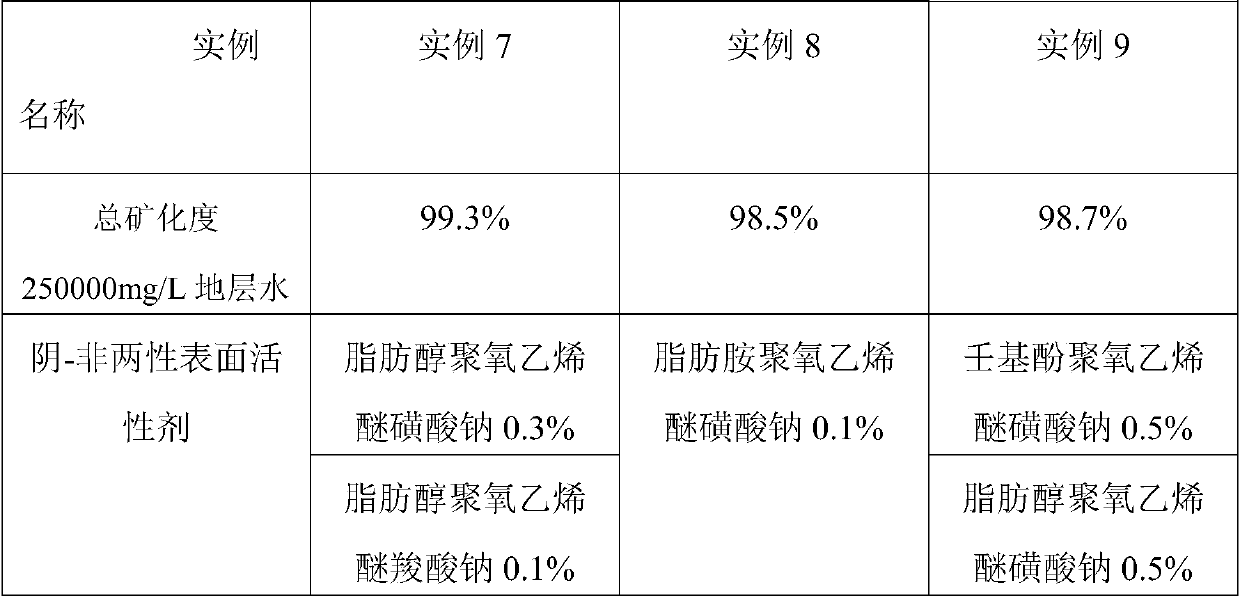

[0036] Example 3 Composite oil displacement agent for high salinity reservoirs at a temperature of 90°C

[0037] Total salinity 250000mg / L, Ca2+, Mg2+ greater than 5000mg / L formation water: 99.3%, xanthan gum: 0.2%, nonylphenol polyoxyethylene ether sulfonate: 0.25%, aliphatic amine polyoxyethylene ether sulfonic acid Salt: 0.25%, stir with a mixer at high speed for 10 minutes to obtain a uniform and transparent composite oil displacing agent. At the same time, after sealing in a 50ml ampule bottle, observe the long-term thermal stability experiment at a constant temperature of 90°C for 6 months, and measure the apparent viscosity and interfacial tension of the solution.

[0038] time (days)

1

180

Solution apparent viscosity (mPa.s)

30.8

25.5

Oil-water interfacial tension (mN / m)

0.05

0.09

[0039] Apparent viscosity is measured by RS-600 rheometer of German Huck Company, and the rotating speed is 6rmp. The interfacial tension was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com