Liquid-solid fluidized bed waste water treatment system for simultaneous carbon, nitrogen and phosphorus removal

A fluidized bed, the technology of the first fluidized bed, applied in the field of fluidized bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

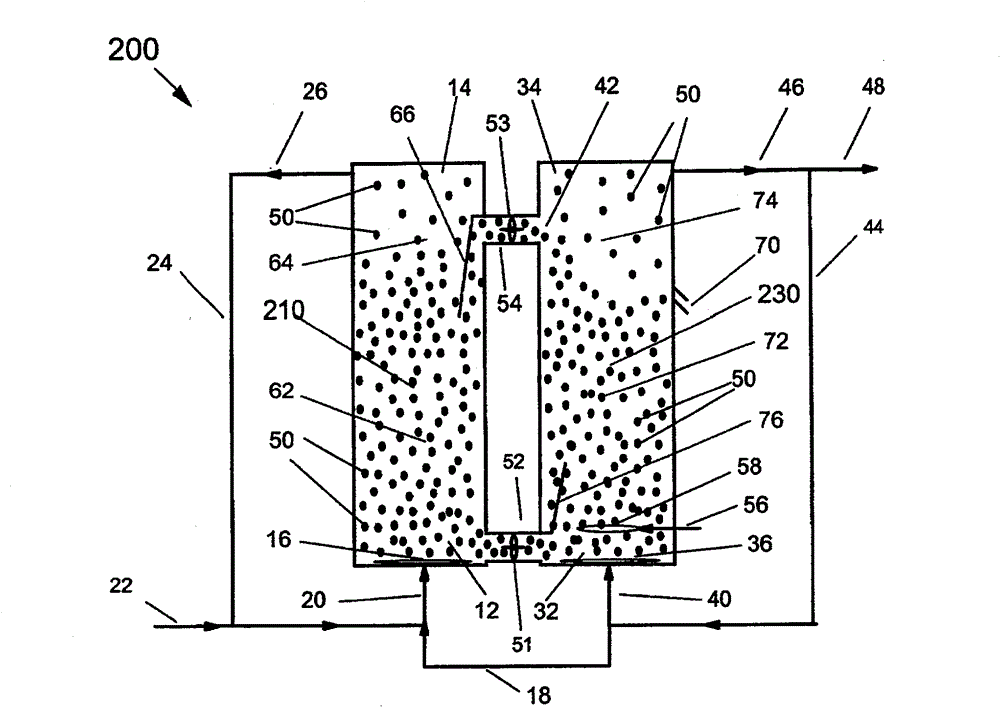

[0096] figure 2 A flow diagram is shown illustrating the use of the dual-LSFB system 200 of the present invention ( Figure 5 ) fixed film BNR process. connect Figure 5 , the aerobic process occurs in the downflow bed 230, the anoxic process occurs in the lower part of the dense phase zone of the upflow bed 210, and the anaerobic process occurs in the upper part of the dense phase zone of the upflow bed 210. Raw sewage 22 (primary influent or primary effluent) is mixed with anoxic / anaerobic effluent recirculation stream 24 from the top of uplifted bed 210 before being injected into the bottom of uplifted bed 210 where the recirculated solid particles The loaded activated sludge along with some previously nitrified sewage from the aerobic process in downflow bed 230 is also mixed with raw sewage 22 and anoxic / anaerobic effluent recycle stream 24 . Fluids containing raw sewage 22 , effluent recirculation stream 24 , previously nitrified sewage, and microbe-laden solid parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com