Auxiliary materials for lamination of flexibility circuit board and lamination process of same

A technology of flexible circuit boards and auxiliary materials, which is applied in the field of flexible circuit boards to achieve the effect of good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Auxiliary material A for lamination

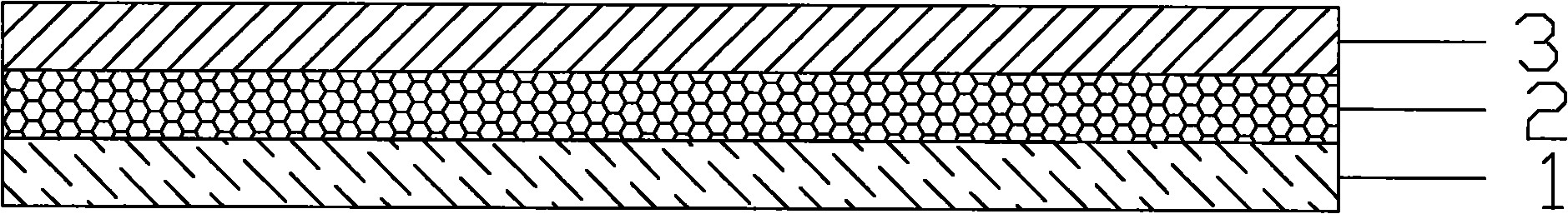

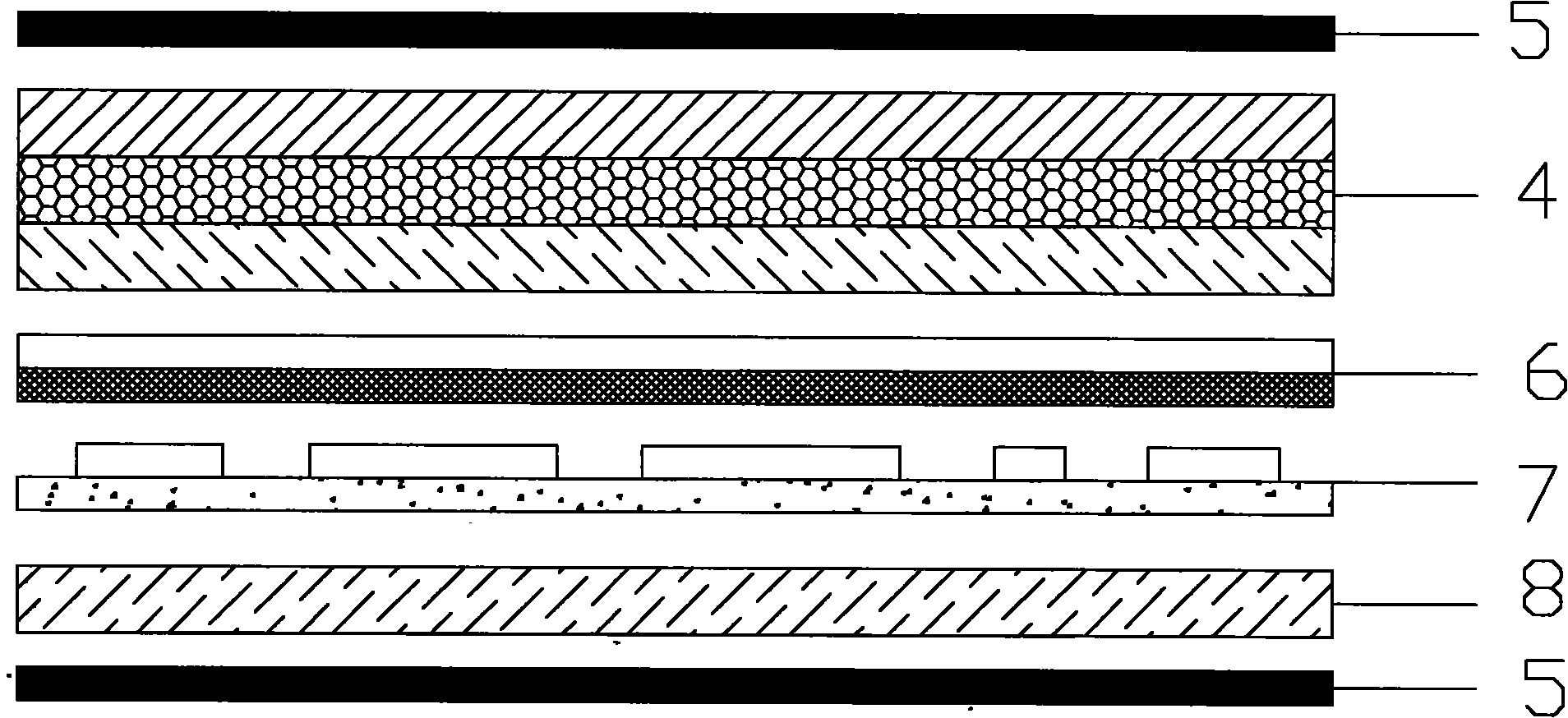

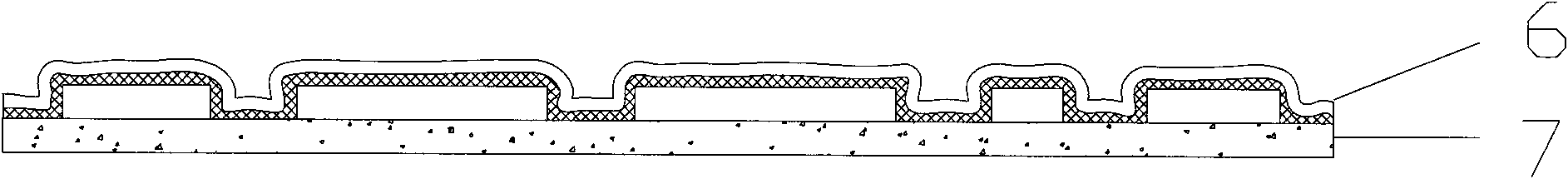

[0046] The physical structure of the auxiliary material A for lamination includes the following layers that are stacked in sequence: a high temperature resistant release film 1, a filling coating material 2, and a deformation control material 3, and the three layers of materials are sequentially combined into one.

[0047] High temperature resistant release film 1 uses FEP film deformation control material with a thickness of 10 μm and 3 biaxially stretched PET film with a thickness of 12 μm

[0048] Adopt tape casting processing technology to be viscous resin (the isooctyl acrylate that 30% viscosity is 2000cPa.s; The vinyl MQ resin that the M / Q=0.75 of 10% by weight is, and 10% by weight is that viscosity is 20000cPa .s hydroxyl-terminated vinyl silicone rubber; 50% by weight of low-density PE plastic particles [brand Shanghai Secco LL0220KJ], the above components are mixed at a high speed to obtain a viscous resin) at ...

Embodiment 2

[0049] Example 2: Auxiliary material B for lamination

[0050] The physical structure of the auxiliary material B for lamination is the same as that of the auxiliary material A for lamination. The high-temperature resistant release film 1 uses a PTFE film with a thickness of 25 μm; the deformation control material 3 uses a biaxially stretched PA film with a thickness of 15 μm

[0051] Adopting coating processing technology to be the copolymer of the isooctyl acrylate / ethyl acrylate of 30% by weight and the aqueous dispersion liquid (all the other being water) of the vinyl MQ resin of the M / Q=0.75 of 20% by weight, Coated on the deformation control material 3 and dried at 110 degrees Celsius to obtain a copolymer containing 60% by weight of isooctyl acrylate / ethyl acrylate and 40% by weight of ethylene with M / Q=0.75 The viscous filling coating material 2 based on MQ resin, with a thickness of 30 μm, is directly combined with the high temperature resistant release film 1 by col...

Embodiment 3

[0052] Example 3: Auxiliary material C for lamination

[0053] The physical structure of the auxiliary material C for lamination is the same as that of the auxiliary material A for lamination. High temperature resistant release film 1 uses FEP film with a thickness of 12 μm; deformation control material 3 uses biaxially stretched PA film with a thickness of 15 μm

[0054] Adopt hot-melt coating process technology to be viscous resin (the weight percent is the isooctyl acrylate of 25000cPa.s; the weight percent is the vinyl MQ resin of 30% M / Q=0.80, and the weight percent is 30% viscosity 20000cPa.s hydroxyl-terminated vinyl silicone rubber heated and kneaded to obtain a viscous resin) hot-melt coated on the deformation control material 3 at 210°C to obtain a filling coating material 2 with a thickness of 30 μm, and then directly bonded with the high-temperature resistant debonding material 2 Molding film 1 is thermocompressed and laminated to obtain auxiliary material C for l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com