Novel electrolyte

An electrolyte and a new technology, applied in the direction of electrolytic capacitors, circuits, capacitors, etc., can solve the problems of high price, easy crystallization, low conductivity of electrolyte, etc., and achieve the effect of easy acquisition and low price

Active Publication Date: 2010-09-22

FUJIAN YUNXING ELECTRONICS

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] 1) Electrolyte with ethylene glycol as the solvent and boric acid and ammonium borate as the solute. In the above electrolyte, boric acid becomes metaboric acid, and the esterification reaction between ethylene glycol and boric acid will generate condensation water , causing the moisture content in the electrolyte to be too high, making it impossible to use it at a temperature exceeding 105°C;

[0004] 2) With ethylene glycol as the solvent and long-chain saturated dicarboxylic acid or its salt as the electrolyte solution of the solute, due to the influence of the steric effect, the motion speed of the straight-chain saturated dicarboxylic acid is small and the solubility is low. The result is The conductivity of the electrolyte is low, and it is easy to crystallize and precipitate under low temperature conditions;

[0005] 3) Using ethylene glycol as a solvent, using branched long-chain saturated dicarboxylic acids or their salts as the electrolyte solution of the solute, the branched long-chain saturated dicarboxylic acids or their salts have a longer solubility in the solvent. The solubility of the chain saturated dicarboxylic acid or its salt is improved, but the formation efficiency and flash voltage of this kind of electrolyte are lower than those of the electrolyte with long straight chain saturated dicarboxylic acid or its salt as the solute;

However, the above-mentioned carbon chain having an alkyl group and an alkoxycarbonyl group and between carboxyl groups at both ends has a high preparation cost, resulting in an increase in the production cost of the electrolyte;

[0007] 5) Tricarboxylic acids with branched chains can also be used. The flash voltage of tricarboxylic acids is higher than that of dicarboxylic acids, but they need to be imported and are expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

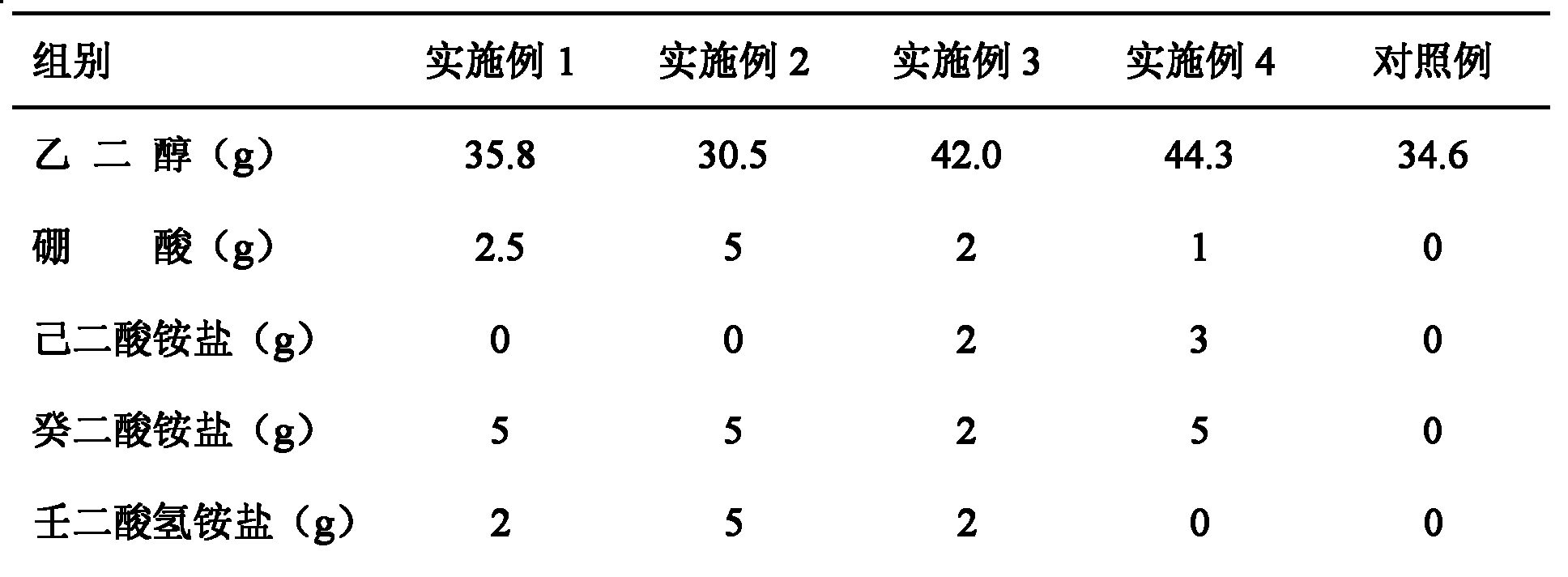

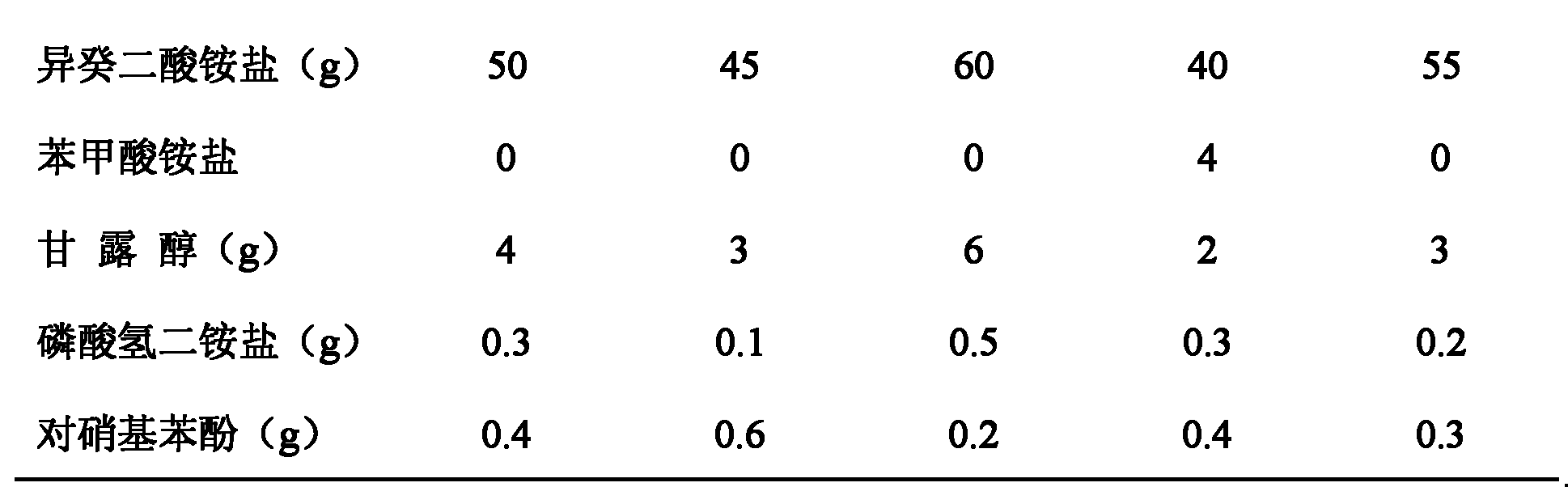

[0028] As shown in Table 1, the electrolyte solution can be obtained by heating the ingredients in the above weight ratio to 150 degrees while stirring.

[0029]

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel electrolyte, which mainly comprises the following components in parts by weight: 30-45 parts of ethylene glycol, 1-5 parts of boric acid, 4-10 parts of at least one kind of long straight-chain saturated dicarboxylic acid or ammonium salt thereof, 40-60 parts of at least one kind of long straight-chain saturated dicarboxylic acid with branched chains or ammonium salt thereof, 2-6 parts of mannitol, 0.1-0.5 part of phosphate and 0.2-0.6 part of dehydrogenation agent. Since the electrolyte uses ethylene glycol as solvent and uses long straight-chain saturated dicarboxylic acid with branched chains, long straight-chain saturated dicarboxylic acid and boric acid as solute, the invention has the advantages that the forming efficiency and the breakdown voltage of the electrolyte are improved, the solubility of the solute is increased, the electric conductivity is improved, the specific resistance is reduced and the service life of the product is improved.

Description

technical field [0001] The invention relates to an electrolytic solution for driving an electrolytic capacitor. Background technique [0002] The working electrolyte is the actual cathode of the electrolytic capacitor, which plays an important role in providing oxygen ions and repairing the anodic oxide film. Therefore, the development of a high-performance working electrolyte is crucial to ensure the performance of the capacitor. The existing electrolytic capacitor driving electrolyte can be roughly divided into the following categories: [0003] 1) Electrolyte with ethylene glycol as the solvent and boric acid and ammonium borate as the solute. In the above electrolyte, boric acid becomes metaboric acid, and the esterification reaction between ethylene glycol and boric acid will generate condensation water , causing the moisture content in the electrolyte to be too high, making it impossible to use it at a temperature exceeding 105°C; [0004] 2) With ethylene glycol as ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01G9/035

Inventor 陈正华

Owner FUJIAN YUNXING ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com