Electroplating layer stress measurement device

A stress measurement and electroplating technology, applied in the direction of force measurement by measuring the change of magnetic properties of materials caused by applied stress, can solve the dispersion, sometimes zero, sometimes fluctuation, can not effectively eliminate the pointer drive wheel static friction, coating stress minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

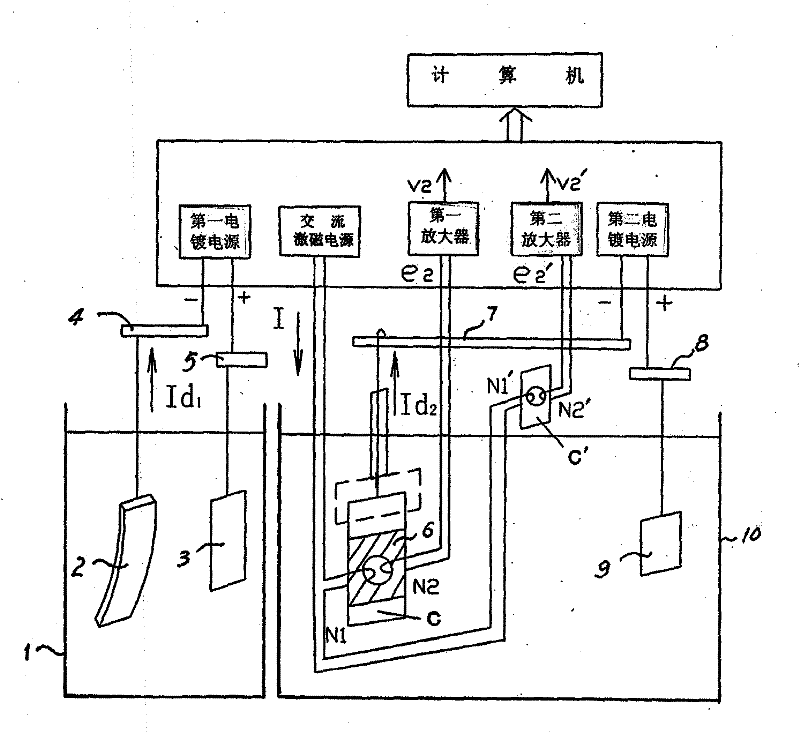

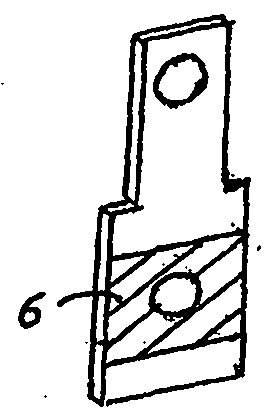

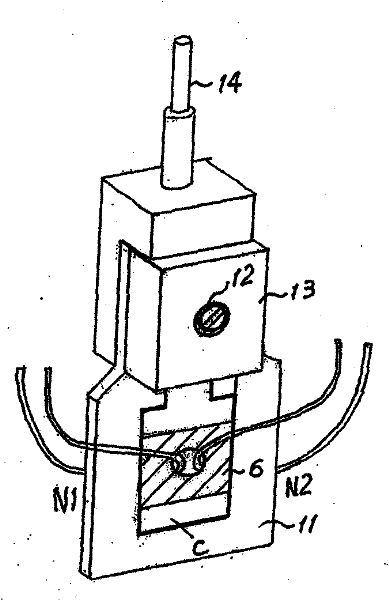

[0059] refer to figure 1 , The electroplating layer stress measuring device of the present invention is composed of an AC excitation power supply, a first electroplating power supply, a second electroplating power supply, a measuring sensor, a calibration sensor, a cathode sheet 2 and a computer. Among them, the frequency of the AC excitation power supply is 400 Hz, and the current is 200 mA, which remain unchanged during the measurement. The first electroplating power supply and the second electroplating power supply are pulse power supplies that can be modulated, and can also be converted into DC power supplies. Wherein the first electroplating power supply provides the electroplating current Id1 for the cathode sheet 2 and the corresponding anode plate 3, and the second electroplating power supply provides the electroplating current Id2 for the first magnetic sensitive sheet C of the measuring sensor and the corresponding anode plate 10, and Id1 and Id2 are measured deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com