Porous biodegradable stent and preparation method thereof

A biodegradable and biodegradable technology, applied in the field of porous biodegradable scaffolds and their preparation, can solve the problem of failing to realize commercialization, and achieve no immune rejection, tissue compatibility and blood compatibility , the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

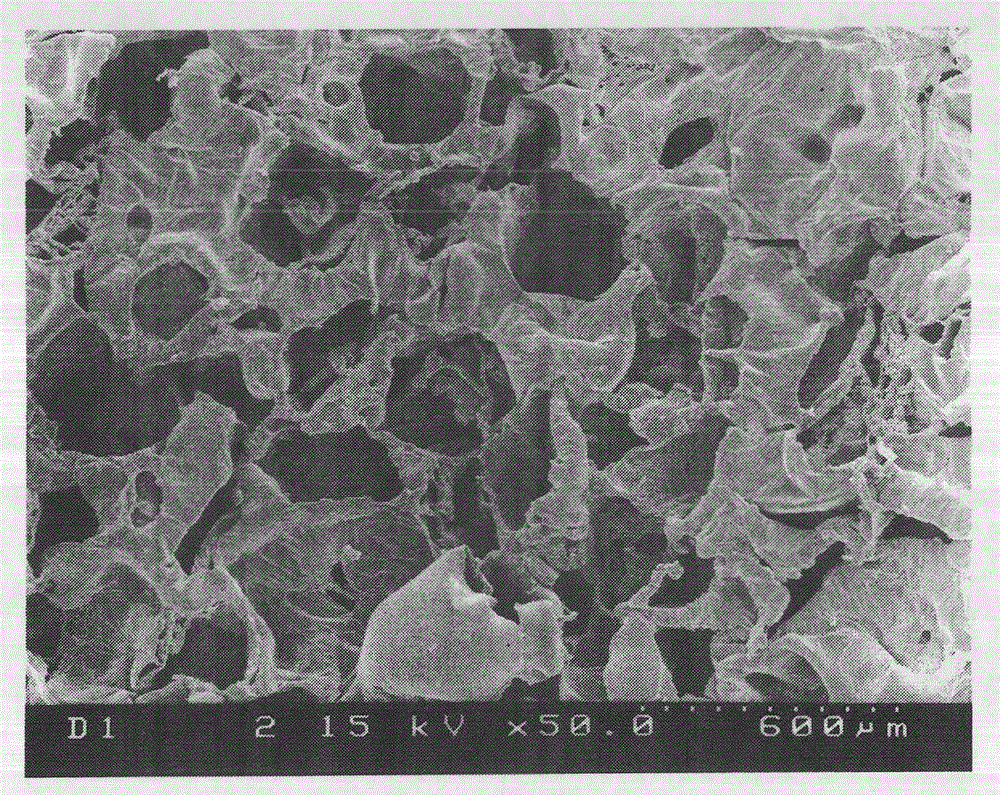

Image

Examples

Embodiment 1

[0039] (1), at normal temperature, PLGA (75PLA: 25PGA) with a molecular weight of 5000 was naturally dissolved in an organic solvent prepared by dichloromethane at 20:80 by weight percentage for 2 hours to form a highly viscous solution;

[0040] (2), according to the weight ratio of sodium chloride and biodegradable polymer is 1: 5, add sodium chloride, stir evenly at normal temperature, mixing and stirring time is 1 minute, form biodegradable polymer, organic solvent and chlorine The pasty mixture of sodium chloride, then the pasty mixture is quickly filled in the plastic mold, under 345 kilopascals pressurized 10 minutes to form semi-finished product;

[0041] (3), drying the semi-finished product at 29°C for 24 hours, removing the organic solvent, and forming a molded product;

[0042] (4), carry out continuous dechlorination to molded product 30 hours with purified water, cause sodium chloride concentration to be less than 3 micrograms / ml;

[0043] (5) After removing sod...

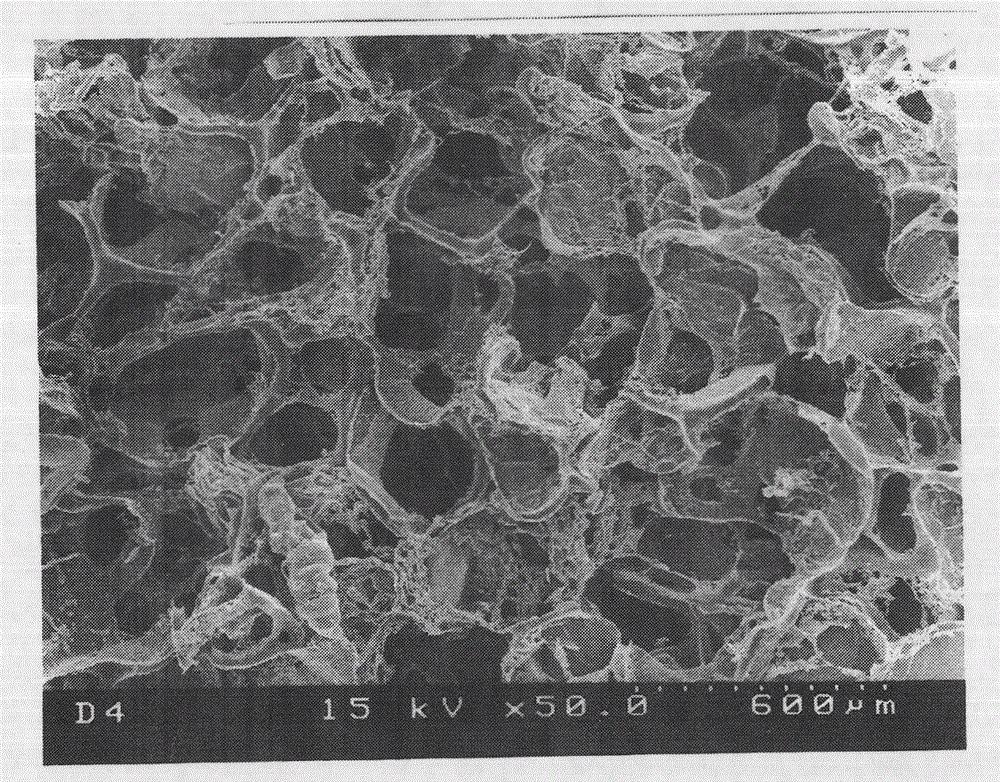

Embodiment 2

[0046] (1), at normal temperature, the PLGA (65PLA: 35PGA) that molecular weight is 200000 is by weight percentage 30: 70 in the organic solvent that is prepared by weight percentage 50: 50 by dichloromethane and acetone naturally for 2.5 hours, forms high viscous solution;

[0047] (2), according to the weight ratio of potassium chloride and biodegradable polymer is 1: 10, add potassium chloride, stir evenly at normal temperature, mixing and stirring time is 2 minutes, form biodegradable polymer, organic solvent and chlorine A paste mixture of potassium chloride, then the paste mixture is quickly filled into a plastic mold, and pressurized at 414 kPa for 9 minutes to form a semi-finished product;

[0048] (3), dry the semi-finished product at 28°C for 30 hours, remove the organic solvent, and form a molded product;

[0049] (4), carry out continuous dechlorination of potassium to molded product for 24 hours with purified water, causing potassium chloride concentration to be ...

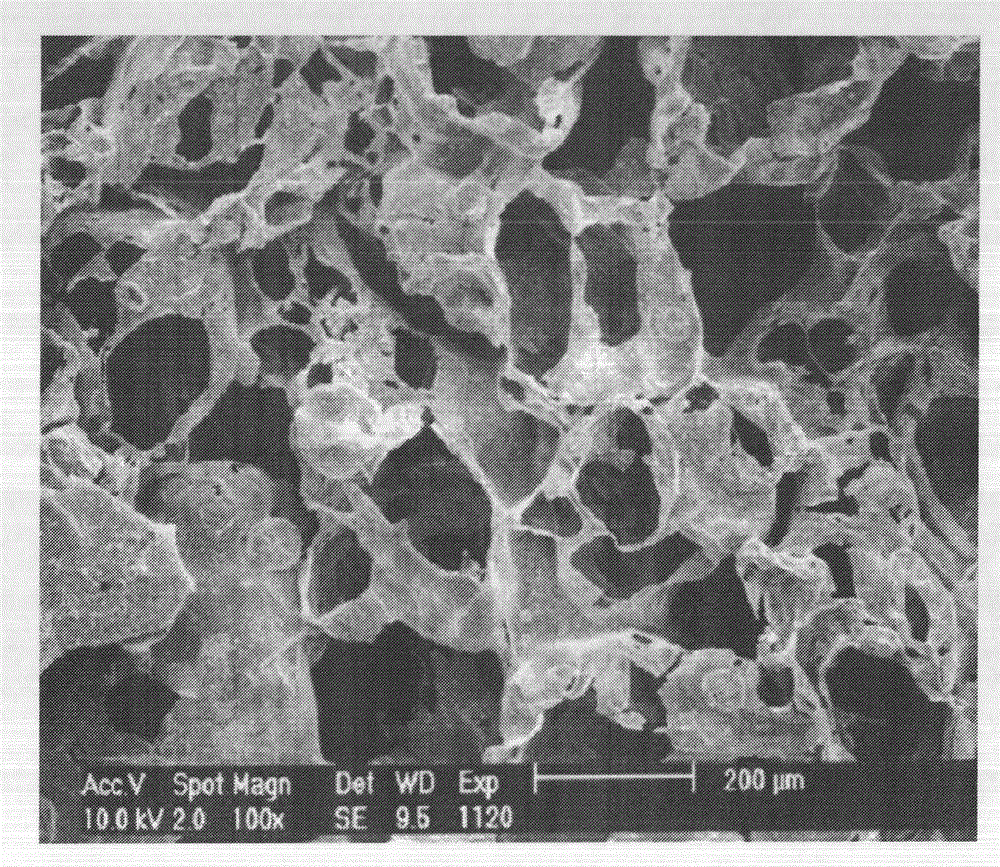

Embodiment 3

[0053] (1), at normal temperature, the PLGA (50PLA: 50PGA) that molecular weight is 350000 is naturally dissolved in the organic solvent prepared by acetone 3 hours by weight percentage 35: 65, forms highly viscous solution;

[0054] (2), add potassium nitrate by the weight ratio of potassium nitrate and biodegradable polymer as 1: 15, stir evenly at normal temperature, mixing and stirring time is 2 minutes, form biodegradable polymer, organic solvent and potassium nitrate Paste mixture, then the paste mixture is quickly filled in the plastic mold, pressurized at 483 kPa for 8 minutes to form a semi-finished product;

[0055] (3), dry the semi-finished product at 27°C for 35 hours, remove the organic solvent, and form a molded product;

[0056] (4), using purified water to carry out continuous denitrification of potassium for 48 hours to the molded product, resulting in a potassium nitrate concentration of less than 3 micrograms / ml;

[0057] (5) After removing potassium nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com