Method for synthesizing methyl isobutyl ketone and diisobutyl ketone by acetone gas-phase one-step method

A technology of methyl isobutyl ketone and diisobutyl ketone, applied in chemical instruments and methods, preparation of organic compounds, preparation of oxygen-containing compounds, etc., can solve the problems of large number of equipment, large investment, long process flow, etc. , to achieve high activity, simple preparation process, and suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

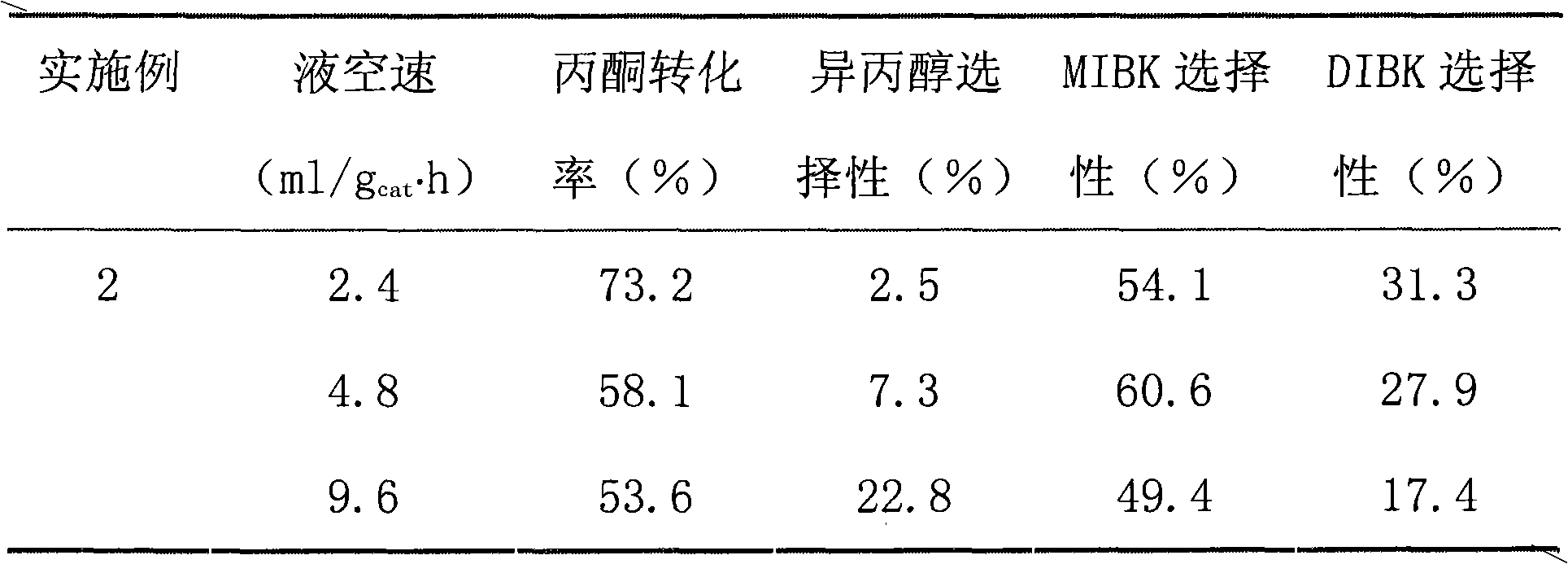

Embodiment 1

[0016] Use freshly boiled distilled water to prepare 1.0mol / L Pd(NO 3 ) 2 , Mg(NO 3 ) 2 , Al(NO 3 ) 3 and 0.5mol / L of Zr(NO 3 ) 4 Metal salt solution; prepare another 1.0mol / L NaOH solution and 0.5mol / L NaOH solution 2 CO 3 solution. According to the catalyst composition Pd: 1wt%, MgO: 55wt%, Al 2 o 3 : 10wt%, ZrO 2 : 34wt%, four kinds of nitrate solutions of Pd, Mg, Al and Zr are made into a mixed solution, and the solution is denoted as A. Add Na to the beaker beforehand 2 CO 3 Solution [CO 3 2- The molar weight of = 0.5 (Al 3+ +Zr 4+ ) molar weight], solution A and NaOH solution are simultaneously titrated into the beaker, the rate of addition is controlled, and the stirring is continued to keep the pH between 9 and 10. After the dropwise addition, stir and age in a constant temperature water bath at 60°C for 12 hours, wash and centrifuge until the pH is around 7, perform suction filtration, put the filter cake in an oven, and dry at 80°C for 12 hours to o...

Embodiment 2

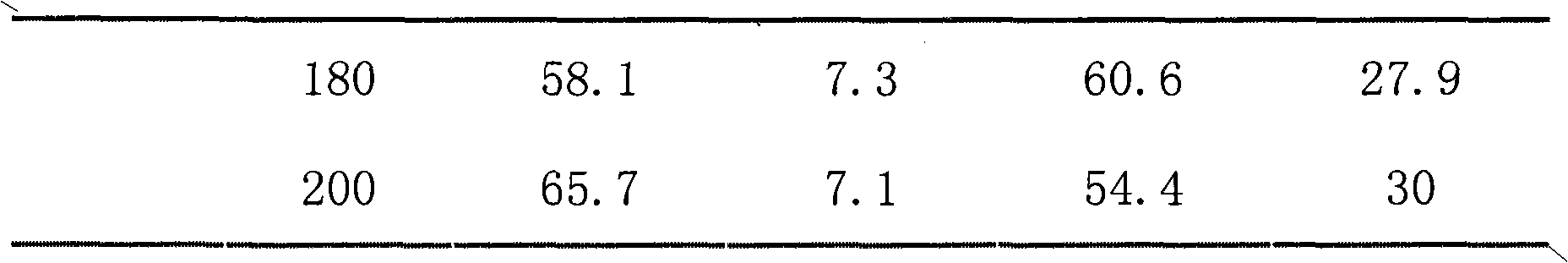

[0019] The catalyst is the same as in Example 1, the reaction temperature is 180° C., the molar ratio of hydrogen to ketone is 1, and the reaction is carried out under different liquid space velocities. The results are shown in attached table 2.

Embodiment 3

[0021] Catalyst is the same as embodiment 1, and reaction temperature is 180 ℃, and liquid space velocity is 4.8ml / g cat h, react under different hydroketone molar ratios, the results are shown in attached table 3.

[0022] Attached Table 1 Catalytic Performance of Catalysts at Different Reaction Temperatures

[0023]

[0024]

[0025] Attached Table 2 Catalytic Performance of Catalysts at Different Liquid Space Velocities

[0026]

[0027] Schedule 3 Different H 2 / Catalytic performance of the catalyst under acetone

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com