Variable rigidity beam, manufacturing method and actuating method thereof

A technology with variable stiffness, applied in the field of MEMS, can solve the problems of reducing device reliability, device design limitations, and poor anti-vibration performance, and achieve the effects of reducing internal stress, improving performance, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The variable stiffness beam proposed by the present invention and its preparation method and actuation method are described as follows in conjunction with the accompanying drawings and embodiments.

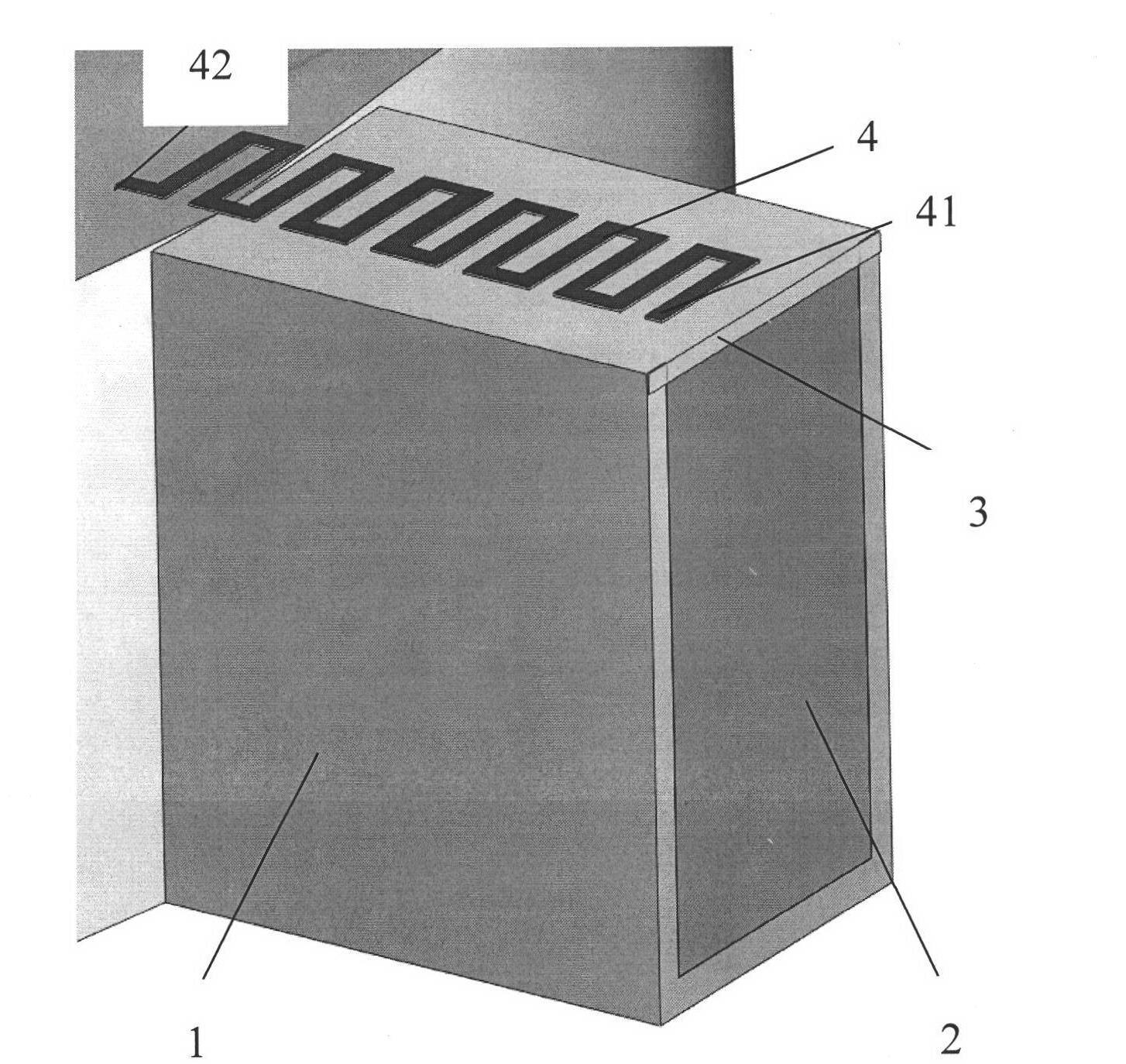

[0027] Such as figure 1 As shown, the variable stiffness beam according to one embodiment of the present invention includes: a frame structure 1; a filling part 2 nested in the frame structure 1; an insulating layer 3 located on the filling part 2; and an insulating layer located on the insulating layer 3 Heating part 4. Among them, the frame structure 1 is made of single crystal silicon material, or polycrystalline silicon, or gallium arsenide, or silicon carbide, or metal material; the filling part 2 is a low melting point material, and when the heating part 4 is heated, the filling part 2 can be solid, All or part of the liquid is converted, thereby changing the stiffness of the variable stiffness beam, in order to realize the core structure of the variable stiffness be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com