Concrete track slab prefabricating construction method of CRTS I type slab ballastless track

A slab ballastless track and concrete technology, which is used in manufacturing tools, ceramic molding machines, etc., achieves the effects of high density, high blanking efficiency, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

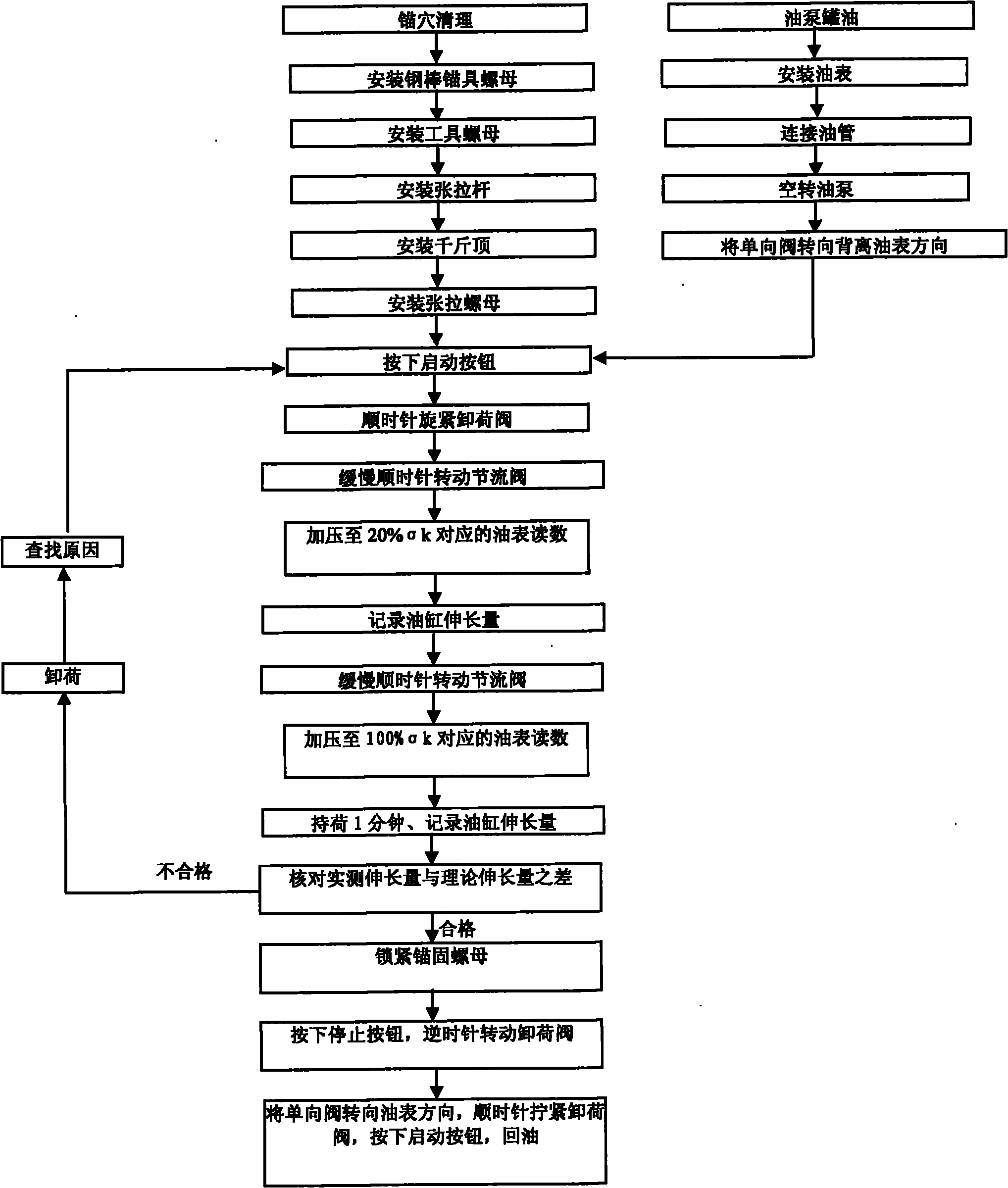

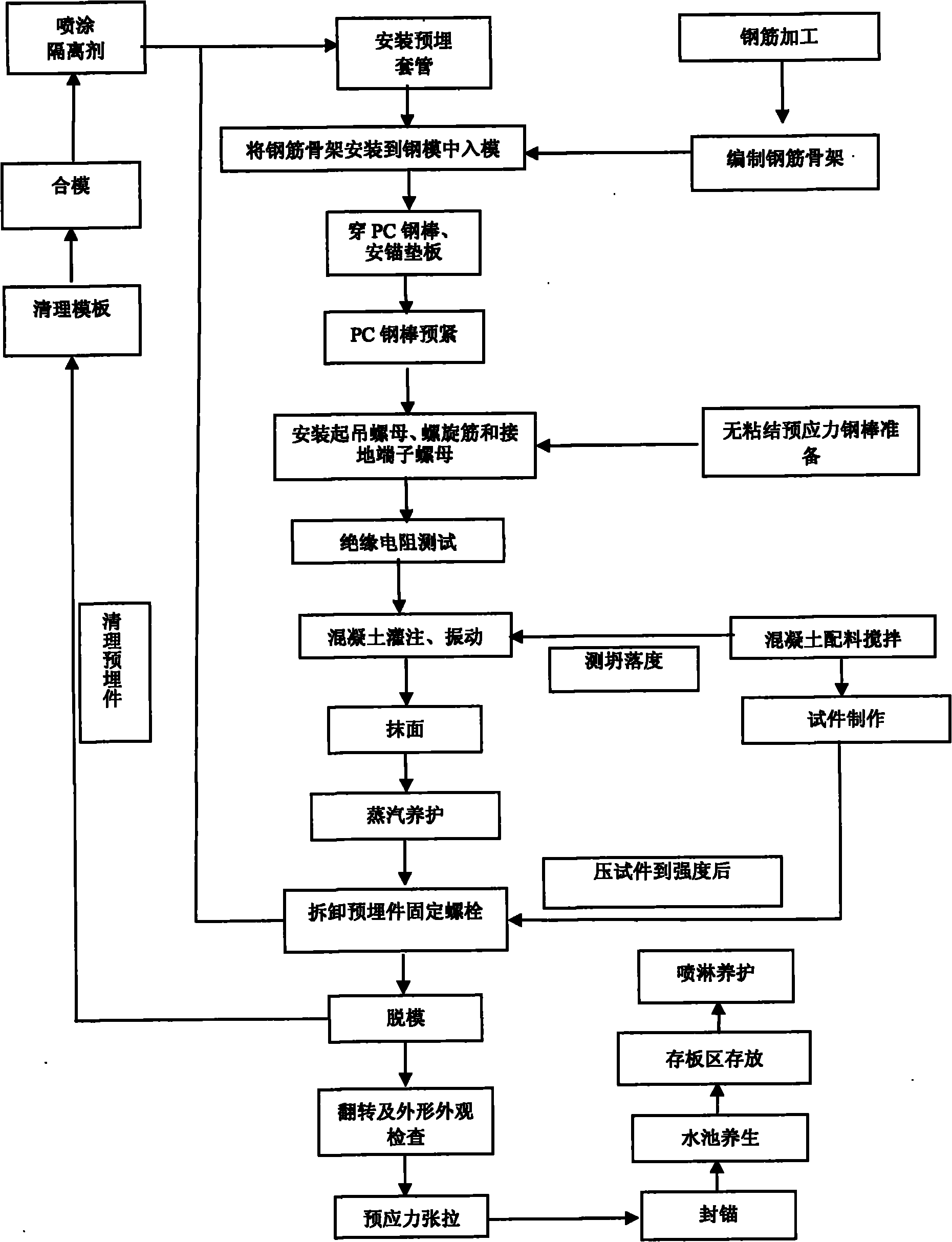

[0044] The CRTS I type slab type ballastless track concrete track slab prefabrication method of the present embodiment is to be constructed in winter, and the temperature is lower than 5 ℃, comprises the following steps (process flow chart is as follows figure 2 shown):

[0045] (1) Preparation of steel skeleton

[0046] (1-1) Technical requirements for steel bar raw materials

[0047] Reinforcement bars must meet the requirements of the current relevant national specifications and the "Interim Technical Conditions for Concrete Track Slabs of CRTS I-Type Ballastless Tracks for Passenger Dedicated Railways". The prestressed tendons are made of low-relaxation unbonded prestressed steel rods, with a nominal diameter of 13mm, and no scratches or other defects on the surface of the steel bars; the tensile strength of PC steel rods is ≥1420Mpa, the yield strength is ≥1280Mpa, and the elongation at break is ≥7%; other The physical and mechanical properties should meet the relevant r...

Embodiment 2

[0316] The CRTS I type slab type ballastless track concrete track slab prefabrication method of the present embodiment is to be constructed in summer, and the temperature is higher than 5 ℃, comprises the following steps (process flow chart as follows figure 2 shown):

[0317] (1) Prepare the steel skeleton;

[0318] (2) steel bar skeleton is installed in the steel mold, is sprayed with release agent and is installed with pre-embedded casing in described steel mold;

[0319] (3) Wearing PC steel rods and anchor pads: Using the track plate mold PC steel rods disclosed in the patent No. 200920302254.3 for rapid positioning and fixing bolts, it can quickly and accurately locate and fix PC steel rods and anchor pads during installation. It is fastened and can be quickly disassembled when the mold is disassembled, which meets the needs of fast and efficient construction. It has the characteristics of simple structure and high efficiency; the positioning time of a single PC steel...

Embodiment 3

[0347] The CRTS I type slab type ballastless track concrete track slab prefabrication method of the present embodiment is to be constructed in summer, and the temperature is higher than 5°C, and includes the following steps (the process flow chart is as follows: figure 2 shown):

[0348] (1) Prepare the steel skeleton;

[0349] (2) steel bar skeleton is installed in the steel mold, is sprayed with release agent and is installed with pre-embedded casing in described steel mold;

[0350] (3) Wearing PC steel rods and anchor pads: The PC steel rods of the track plate mold disclosed in the patent No. 200920302254.3 are used for rapid positioning and fixing bolts, which can quickly and accurately position and fix the PC steel rods and anchor pads during installation. It is fastened and can be quickly disassembled when the mold is disassembled, which meets the needs of fast and efficient construction. It has the characteristics of simple structure and high efficiency; the positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com