Ion deodorization centralized treatment box

A concentrated treatment and ion technology, applied in deodorization, disinfection, etc., can solve the problems of low treatment efficiency, uneven mixing, poor mixing effect, etc., and achieve the effect of thorough reaction, uniform mixing and thorough purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

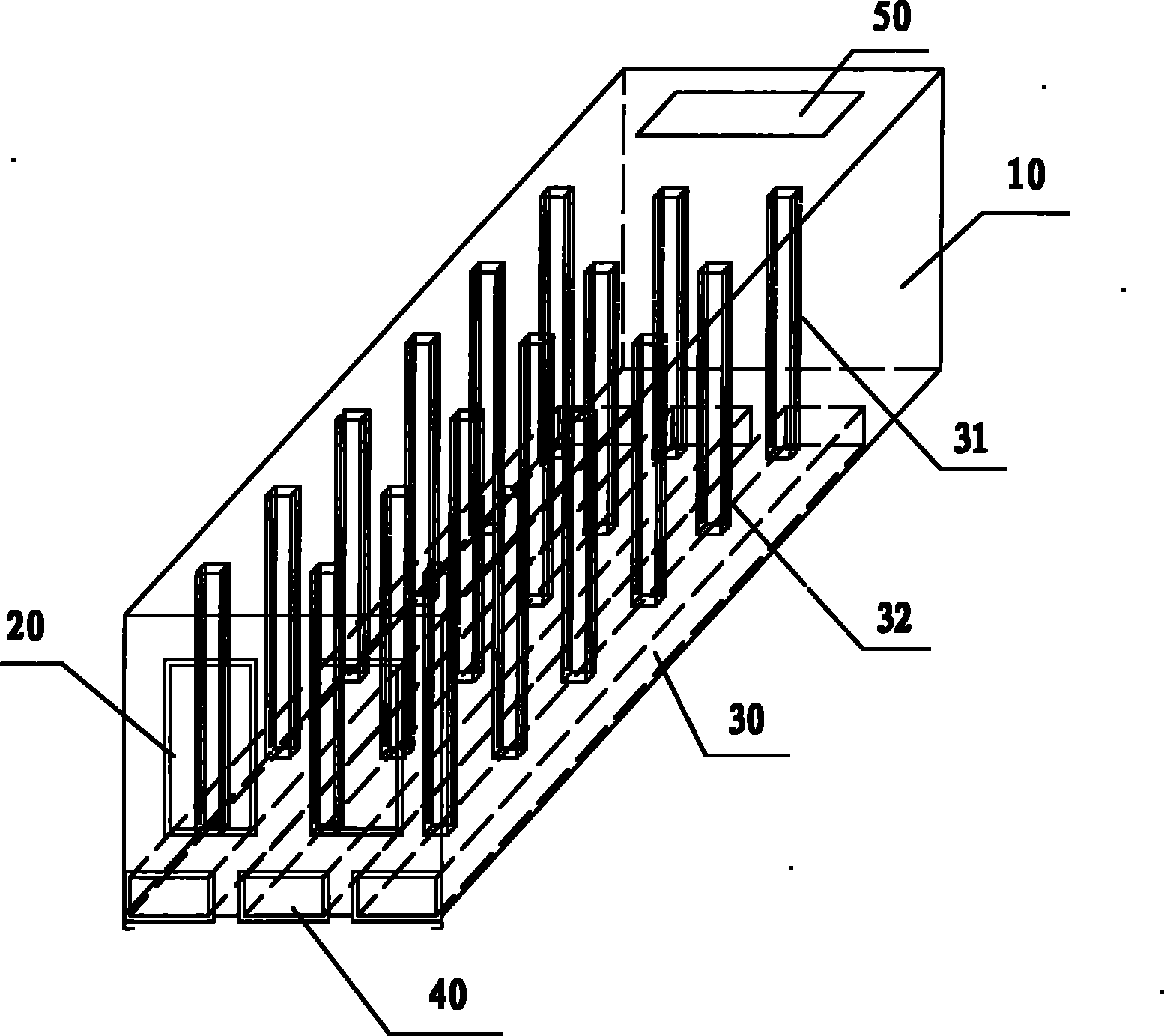

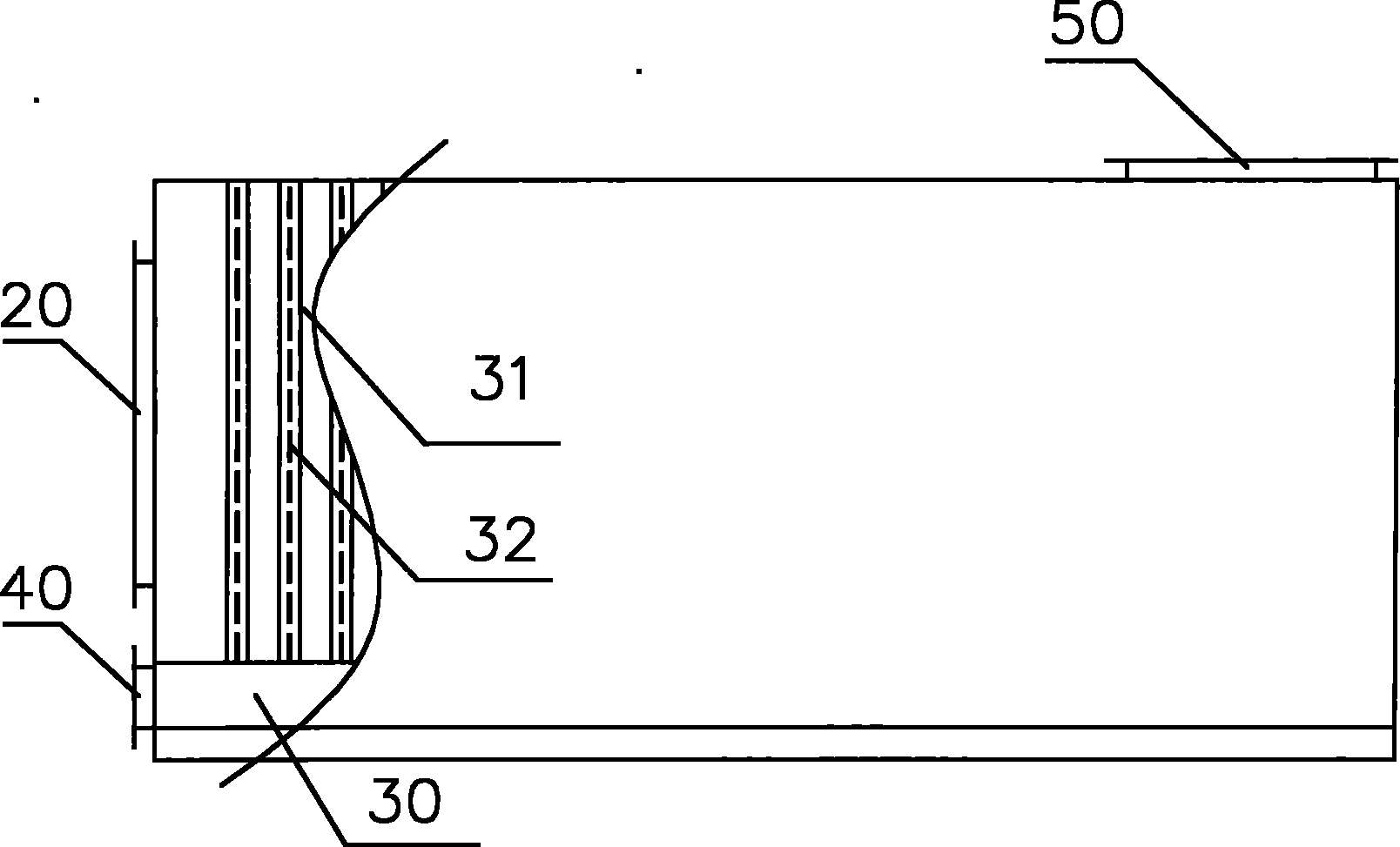

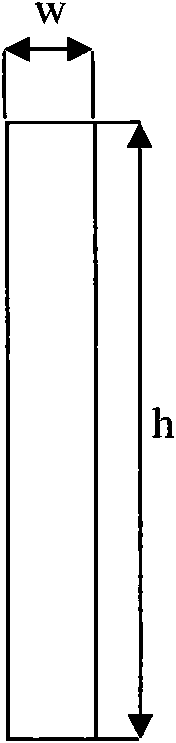

[0037] Such as Figure 1 ~ Figure 2 Shown is a single-layer structure ion concentration treatment box, the concentration treatment box includes a box body 10, two first air inlets 20 are arranged on one side of the box body 10; Three second air inlets 40 are also arranged on the top; at the bottom of the box body 10, three air distribution ducts 30 corresponding to the second air inlets 40 are arranged, and one end of each air distribution duct 30 is connected to a corresponding second air inlet. The air outlet 40 is connected, and the other end is closed; the air distribution duct 30 is parallel to the plane of the bottom of the box body 10, and the malodorous gas to be treated is imported into the box body 10 from the second air inlet 40 through the corresponding air distribution duct 30; Each of the air distribution ducts 30 is also vertically provided with several ventilation branch pipes 31, and the air distribution duct 30 communicates with the ventilation branch pipes 3...

Embodiment 2

[0049] Such as Figure 4 The ion concentration processing box shown has a double-layer structure. The centralized processing box of the present embodiment comprises a box body 10, and a first air inlet 20 is arranged at the center of the side of the box body 10; several second air inlets 40 are respectively arranged at the upper and lower ends of the same side of the first air inlet 20; The middle part of the box body 10 is provided with an air distribution duct 30. The air distribution duct 30 is a box-type structure. One end of the air distribution duct 30 is connected to the second air inlet 40, and the other end is closed. The top and bottom of 30 are vertically provided with a number of ventilation branch pipes 31, the top of the ventilation branch pipe 31 is closed, the bottom end communicates with the air distribution duct 30, and several slit-like through holes 32 are provided on the ventilation branch pipe 31, and each ventilation branch pipe The top end of the branc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com