Dust removal type concrete spraying machine

A technology of concrete spraying machine and dust removal device, which is applied in earthwork drilling, shaft lining, tunnel lining, etc. It can solve the problems of polluting the working environment, material waste, spraying dust discharge, etc., and achieves good dust removal effect and avoids air pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

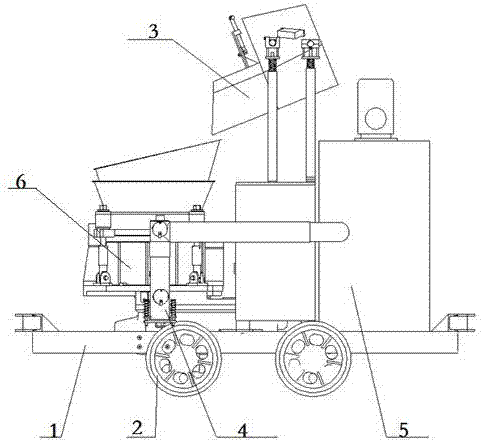

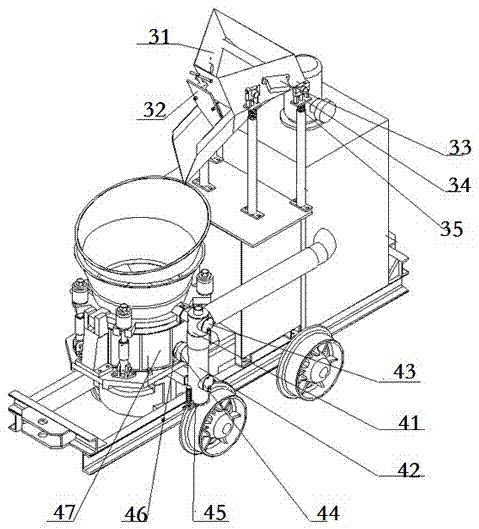

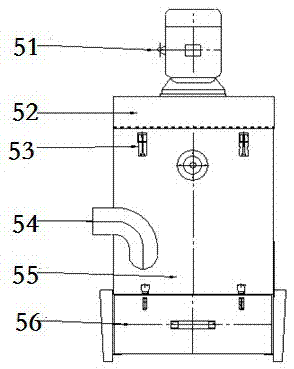

[0027] Embodiment one of the dust removal type concrete sprayer of the present invention, as Figure 1~6 As shown, it includes a chassis 1, a walking wheel 2 installed under the chassis 1, a concrete sprayer body 6 installed on the chassis 1, an automatic quick-setting agent addition mechanism 3 and a dust removal device 5, and the quick-setting agent automatic addition mechanism 3 is arranged on Above the side of the concrete sprayer body 6, the concrete sprayer body 6 includes a dust discharge mechanism 4, and the dust discharge mechanism 4 is connected to the dust removal device 5 through an exhaust pipe. The concrete sprayer body includes a reducer 62, a rotor body assembly 61 connected to the output shaft of the reducer 62, a panel 63 arranged between the reducer 62 and the rotor body assembly 61, and a shield surrounding the rotor body assembly 61 47. A rotor body assembly 61 is installed on the upper part of the reducer 62, a hopper seat 65 is arranged above the rotor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com