Reinforced concrete lightweight board

A technology of reinforced concrete and lightweight slabs, applied in the direction of floor slabs, formwork/formwork/work frames, structural elements, etc., can solve the problems of reducing construction speed and increasing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

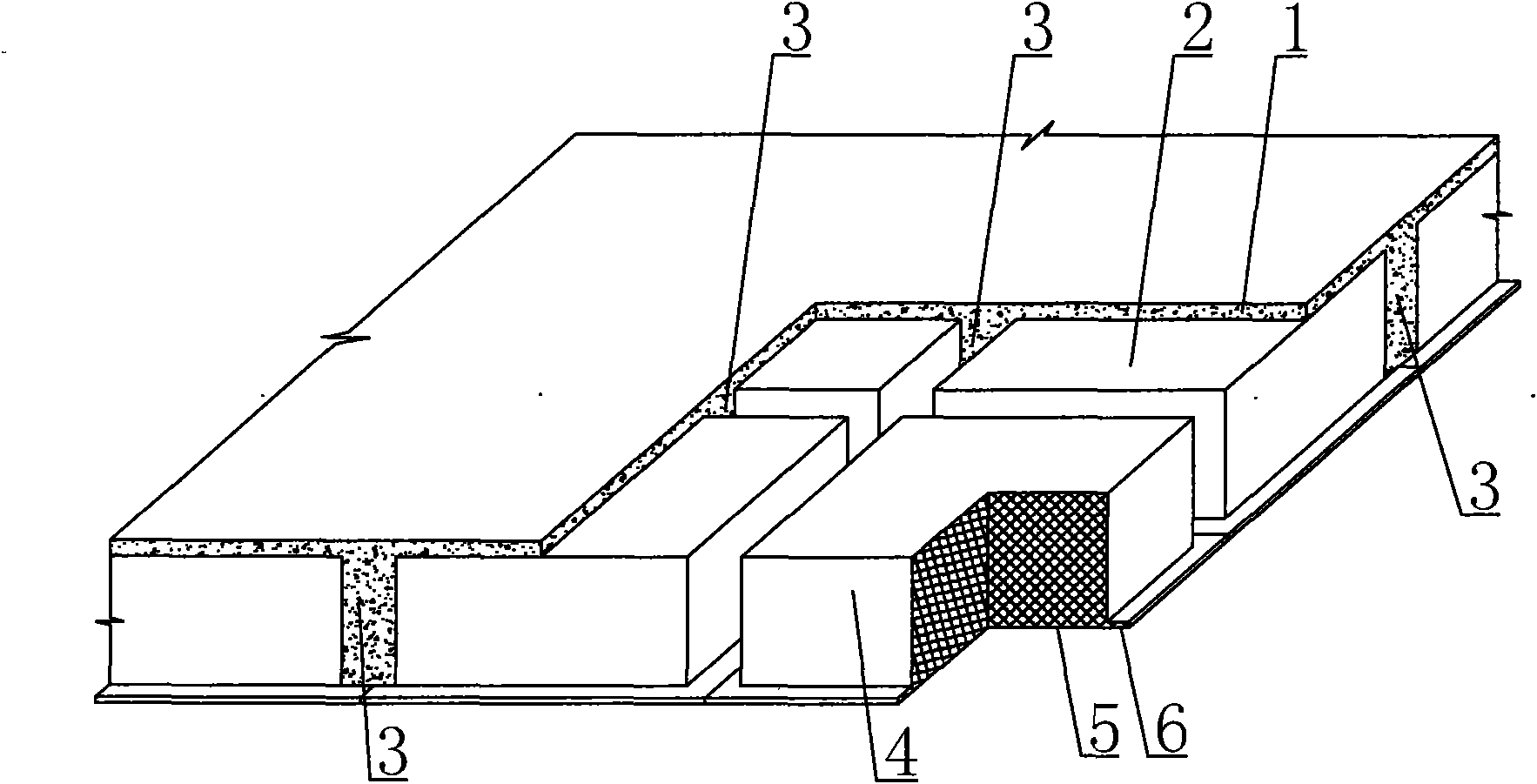

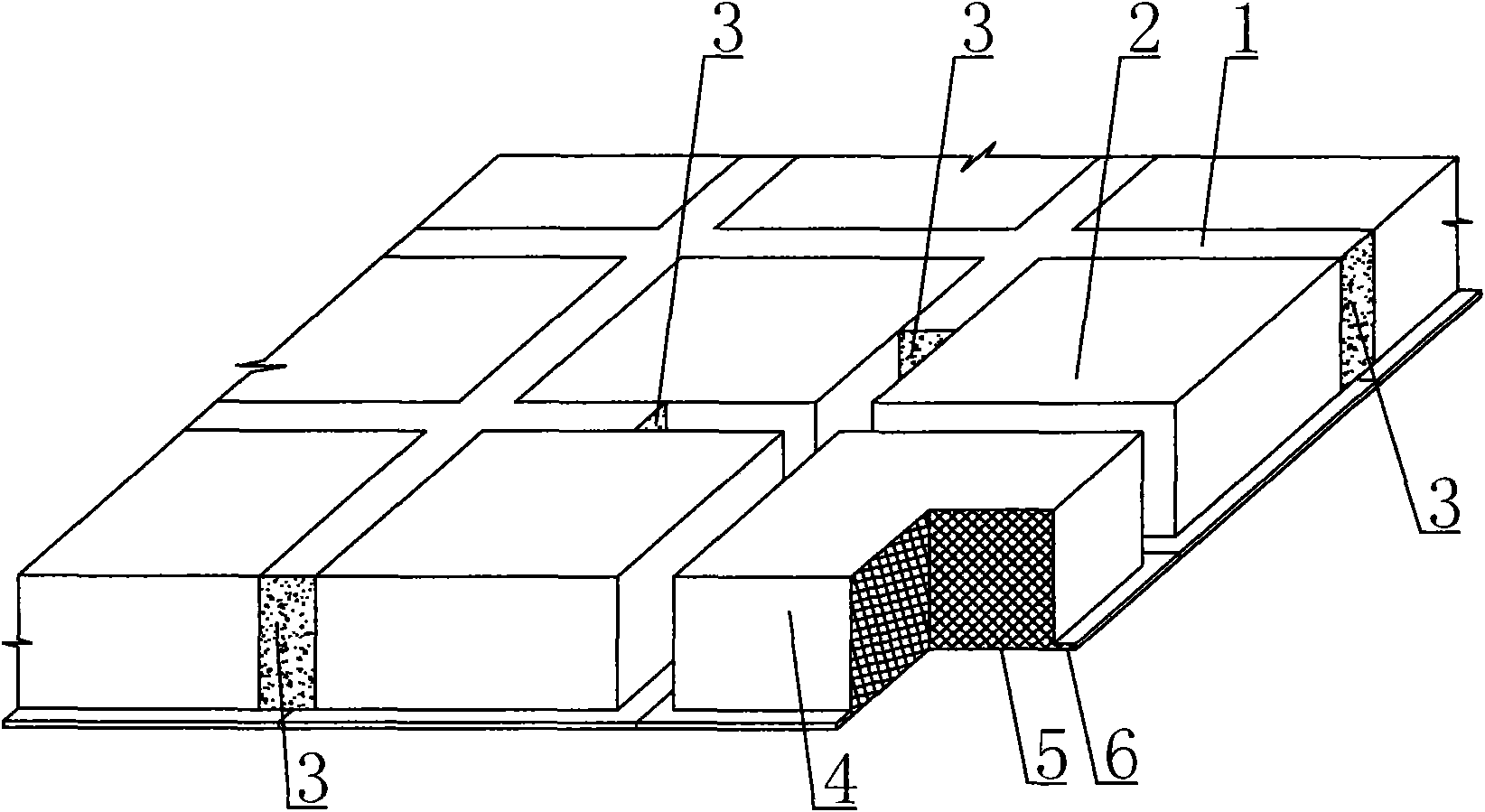

[0045] As shown in the accompanying drawings, the present invention includes reinforced concrete 1 and solid lightweight components 2, the solid lightweight components 2 are wrapped in reinforced concrete 1, the solid lightweight components 2 are arranged alternately, and there are cast-in-place reinforced concrete ribs 3 between them , characterized in that at least one surrounding side 4 of the solid lightweight member 2 protrudes outward along the bottom surface 5 with a pick plate 6, and the bottom surface 5 is flush with the bottom surface of the reinforced concrete lightweight board. In each drawing, 1 is reinforced concrete, 2 is solid lightweight component, 3 is cast-in-place reinforced concrete rib, 4 is surrounding side, 5 is bottom surface, 6 is pick plate, in the following drawings, the number is the same, its The instructions are the same. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com