Fully-degradable polylactic acid fiber melt-blowing nonwoven and preparation method thereof

A technology of melt-blown non-woven fabrics and polylactic acid fibers, which is applied in non-woven fabrics, melt-spinning, textiles and papermaking, etc., can solve the problems of low strength of melt-blown non-woven fabrics, large vertical and horizontal strength, and uneven fibers. , to achieve the effect of good process stability, stable quality and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

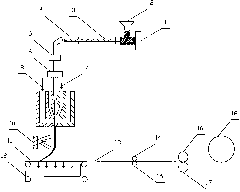

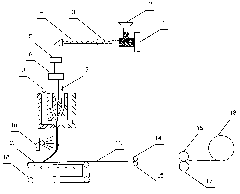

[0041] The specific implementation process of the present invention will be further described below in conjunction with examples. The preparation method of the invention adopts novel fully degradable PLA slices as raw materials, and prepares non-woven fabrics by a melt blown process. The PLA melt-blown nonwoven fabric process prepared by the present invention mainly includes the following four steps: (1) PLA chip selection and drying. (2) Melt extrusion process. (3) Spinning and stretching process. (4) Web forming process. (5) Hot rolling reinforcement process. According to the prior art, the technical problems to be solved are mainly the selection and drying of PLA chips, melt spinning process, web forming process and hot rolling process parameters.

[0042] Considering the rheology and melt viscosity of the PLA melt after melting the slices, the melt blown process has the following requirements for the PLA slices: the molecular weight of the slices should be concentrated...

Embodiment 1

[0059] (1) PLA slices were dried. The PLA slices are put into continuous drying equipment for full drying. The molecular weight of the slices is 100,000, the melt index is 80-85, and the thermal cracking temperature is 305°C. The drying temperature is 100°C, the drying time is 5 hours, and the water content of the PLA chips is 22ppm after drying.

[0060] (2) PLA chip melt extrusion process. The screw pitch is 3mm, the length-to-diameter ratio (L / D) is 30, the screw speed is 25rpm, the internal temperature of the screw extruder is 208°C, the box temperature is 190°C, the feed section is 150°C, and the compression section is 180°C. °C, the metering section is at 215 °C. The temperature of the melt-blown die head is 195°C, the hole diameter is 0.2mm, and the melt extrusion rate is 0.344g / (hole·min).

[0061] (3) PLA filament stretching process. The hot air temperature is 205°C, the hot air velocity is 600m / s, the pressure is 0.3Mpa, the hot air injection angle is 60°, the co...

Embodiment 2

[0069] (1) PLA slices were dried. The PLA slices are put into continuous drying equipment for full drying. The molecular weight of the slices is 100,000, the melt index is 80-85, and the thermal cracking temperature is 340°C. The drying temperature is 80°C, the drying time is 8 hours, and the moisture content of the PLA chips is 18ppm after drying.

[0070] (2) PLA chip melt extrusion process. The screw pitch is 3mm, the length-to-diameter ratio (L / D) is 35, the screw speed is 45rpm, the internal temperature of the screw extruder is 198°C, the box temperature is 190°C, the feed section is 155°C, and the compression section is 185°C. °C, the metering section is at 210 °C. The temperature of the melt-blown die head is 185°C, the hole diameter is 0.2mm, and the melt extrusion rate is 0.144g / (hole·min).

[0071] (3) PLA filament stretching process. The hot air temperature is 195°C, the hot air velocity is 800m / s, the pressure is 0.28Mpa, the hot air injection angle is 60°, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fineness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com