Grinding and cooling liquid purification method and device thereof

A technology of cooling liquid and grinding liquid, which is applied in the field of devices realizing the method, can solve the problems of less grinding iron filings, affect the surrounding environment, affect the grinding effect, etc., and achieve the goal of saving cooling liquid materials and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the protection scope of the present invention is not limited to the scope described in the examples.

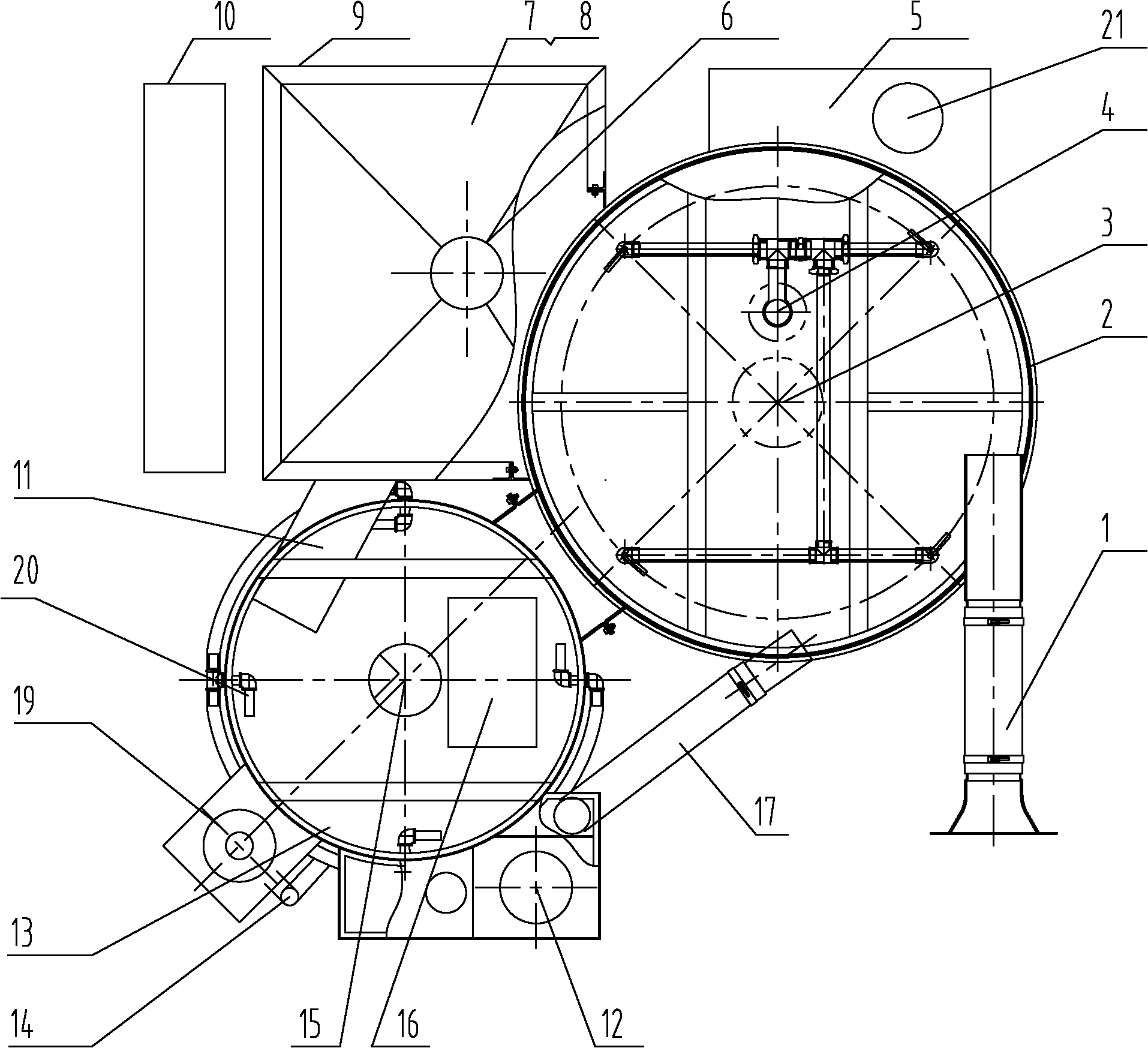

[0018] see figure 1 The outlet of the water connection pipe 1 is connected with a first cylindrical funnel-shaped water tank 2 in a tangential direction, and the bottom of the funnel of the first circular funnel-shaped water tank 2 passes through a first water pump 3 and a magnetic separator 7 and a paper filter 8 are installed. The water inlet pipe 6 of the separation water tank 9 is connected, the slag outlet of the separation water tank 9 is connected with the slag receiving box 10, the drain pipe 11 of the separation water tank is connected with the second cylindrical funnel-shaped water tank 13 in a tangential direction, and the second cylindrical funnel-shaped water tank The bottom of the funnel of 13 is connected with the water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com