Bearing cleaning integrated machine

A bearing cleaning and integrated machine technology, applied in dryers, drying gas layout, cleaning methods and utensils, etc., can solve problems such as inability to clean, achieve good cleaning effect, avoid waste, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

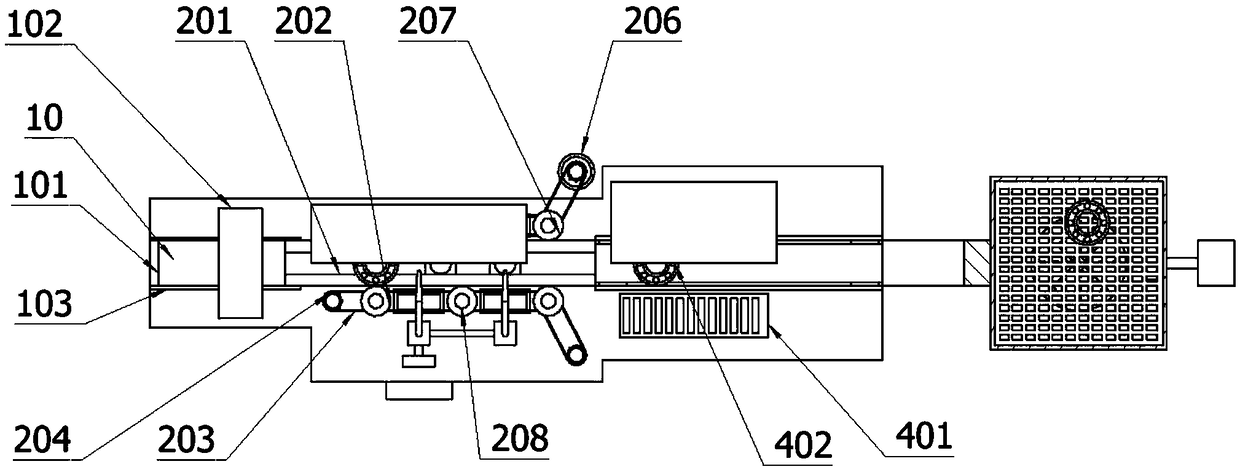

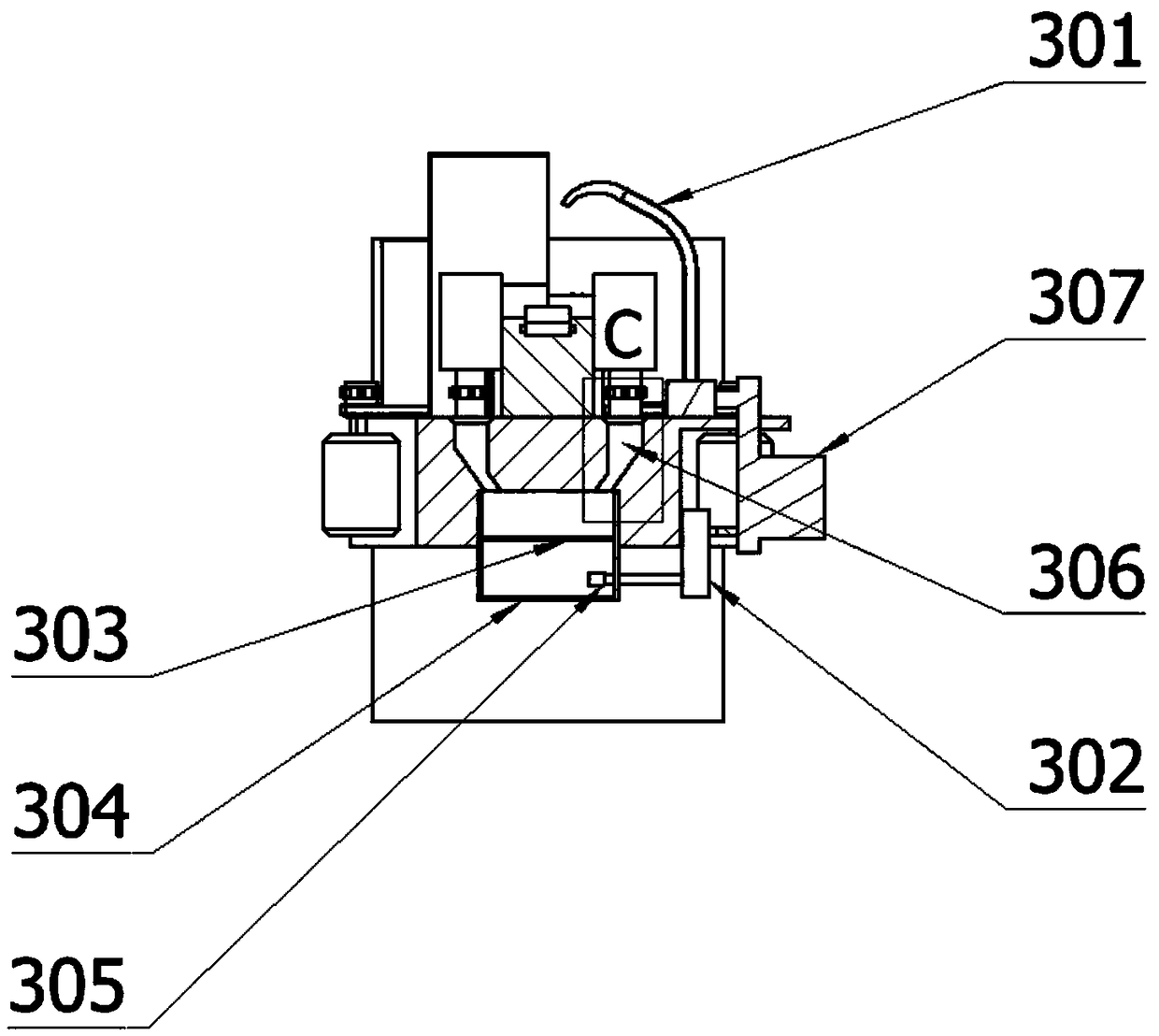

[0042] The invention provides an all-in-one machine for cleaning bearings. Through the cooperation of the transmission unit, the rotation unit and the cleaning unit, it effectively solves the technical problem of cleaning dead angles caused by the static state in the bearing cleaning process, and then realizes efficient and environmentally friendly cleaning, and Fast drying after bearing cleaning is realized by the drying unit.

[0043] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0044]An embodiment of the present application provides an all-in-one cleaning machine for bearings, including a base, a feeding unit, a conveying unit, a rotating unit, a cleaning unit and a drying unit. There is a first rectangular groove in the middle of the base; the feeding unit is connected to the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com