Cast-in-place pile foundation sewage removal system based on rotary tooth rake type sewage removal machine

A technology of cast-in-situ piles and rotary teeth, which is applied in sheet pile walls, foundation structure engineering, water conservancy projects, etc., can solve the problems that the rotary tooth rake type cleaning machine cannot be put into use, and the stagnant reservoir area cannot be cleaned, so as to save labor , good reliability and good ecological benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

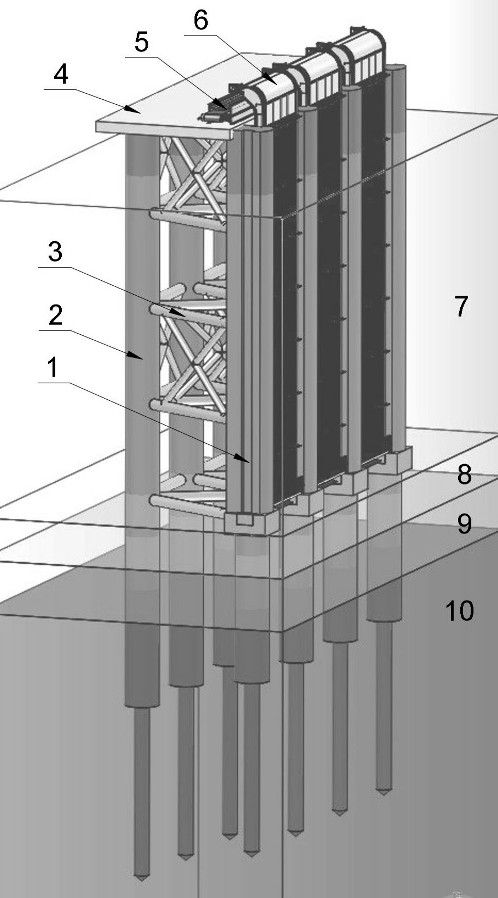

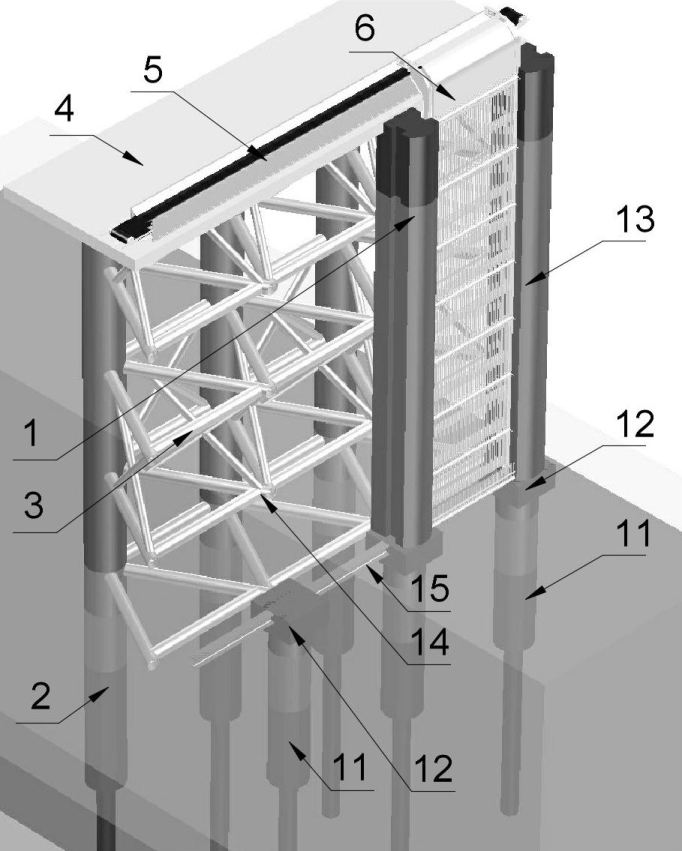

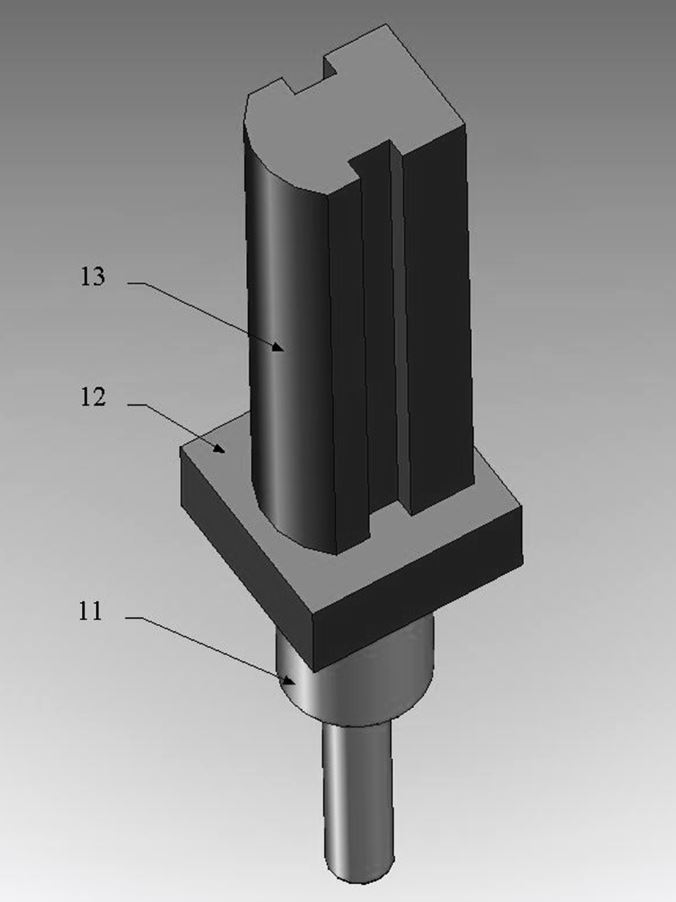

[0012] The following is a detailed description of the cast-in-place pile foundation cleaning system based on the rotary tooth rake cleaning machine combined with the attached drawings:

[0013] The cast-in-place pile foundation cleaning system based on the rotary tooth rake cleaning machine mainly consists of the front row of cast-in-place pile piers 1, the rear row of cast-in-place piles 2, the truss interconnection system 3, the cleaning bridge 4, the belt conveyor 5, The rotary tooth rake type cleaning machine is composed of 6, which is characterized in that the front row of cast-in-place pile piers 1 and the rear row of cast-in-place piles 2 are connected and reinforced through the truss interconnection system 3, and are scientifically integrated with the cleaning bridge 4 set on the top. It is effectively combined into a stable cleaning platform, and at the same time, a trash rack groove is designed in the front row of cast-in-place pier 1 for installing the rotary tooth r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com