Compound feed additive for preventing and controlling ketosis of dairy cows and preparation method thereof

A feed additive and cow ketone technology, which is applied in the field of compound feed additives and preparations for preventing and treating cow ketosis, can solve the problems of incomplete curative effect and inability to treat ketosis, achieve obvious curative effect, increase glycogen, relieve acidosis, and bioutilize high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

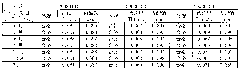

Embodiment 1

[0012] Weigh 20 parts of codonopsis, 20 parts of astragalus, 20 parts of hawthorn, 20 parts of tangerine peel, 20 parts of angelica, 20 parts of red peony, 20 parts of chuanxiong, 20 parts of rehmannia, 20 parts of motherwort, 20 parts of fenugreek, propionic acid 46.5 parts of sodium, 0.05 parts of cobalt sulfate, 0.2 parts of copper sulfate, 0.5 parts of manganese sulfate, 0.5 parts of niacin, vitamin D 3 0.5 parts, 8 parts of calcium dihydrogen phosphate, and 4 parts of citric acid. Add water to decoct the ten traditional Chinese medicines twice, each time for 2 hours, concentrate to 50°C to measure the clear paste with a relative density of 1.25-1.28, and put it in a drying oven at 80°C to form an extract powder, mix it with the remaining raw materials evenly, and wait until mechanically supercharged. In a micro pulverizer, pulverize into 0.1-30 μm fine powder, pack separately, and obtain.

Embodiment 2

[0014] Weigh 5 parts of codonopsis, 5 parts of astragalus, 30 parts of hawthorn, 30 parts of tangerine peel, 30 parts of angelica, 10 parts of red peony, 10 parts of chuanxiong, 10 parts of rehmannia, 40 parts of motherwort, 10 parts of fenugreek, propionic acid 34.4 parts of sodium, 0.05 parts of cobalt sulfate, 0.2 parts of copper sulfate, 0.5 parts of manganese sulfate, 0.5 parts of niacin, vitamin D 3 0.6 parts, 10 parts of calcium dihydrogen phosphate, 4 parts of citric acid. Decoct the ten flavors of traditional Chinese medicine with water twice, each time for 2 hours, concentrate to 50°C and measure the clear paste with a relative density of 1.25-1.28, and put it in a drying oven at 80°C to form an extract powder, mix it with the remaining raw materials evenly, and place it in a vibrating mill , pulverize into 0.1-30 μm micropowder, pack separately, and obtain.

Embodiment 3

[0016] Weigh 40 parts of Codonopsis, 50 parts of Astragalus, 10 parts of hawthorn, 10 parts of tangerine peel, 20 parts of angelica, 20 parts of red peony, 20 parts of Chuanxiong, 10 parts of Rehmannia glutinosa, 30 parts of motherwort, 10 parts of fenugreek, propionic acid 71.8 parts of sodium, 0.05 parts of cobalt sulfate, 0.2 parts of copper sulfate, 0.5 parts of manganese sulfate, 0.5 parts of niacin, vitamin D 3 0.2 parts, 4 parts of calcium dihydrogen phosphate, and 3 parts of citric acid. Decoct the ten traditional Chinese medicines with water twice, each time for 2 hours, concentrate to 50°C and measure the clear paste with a relative density of 1.25-1.28, put it in a drying oven at 80°C to form extract powder, mix with the remaining raw materials evenly, and then airflow crush In the machine, pulverize into 0.1-30μm fine powder, pack separately, and obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com