Process for manufacturing muffler

A manufacturing process and technology of mufflers, applied in mufflers, machines/engines, engine components, etc., can solve the problems of high surface temperature and easy burns, low mechanical strength, low efficiency, etc., and achieve low noise, low surface temperature, and accurate assembly. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further illustrate the principle and structure of the self-heating moxibustion patch and processing method of the present invention, the preferred embodiments of the self-heating moxibustion patch and processing method of the present invention will be described in detail in conjunction with the accompanying drawings, but the embodiments are only for illustration and explanation It cannot be used to limit the scope of patent protection of the present invention.

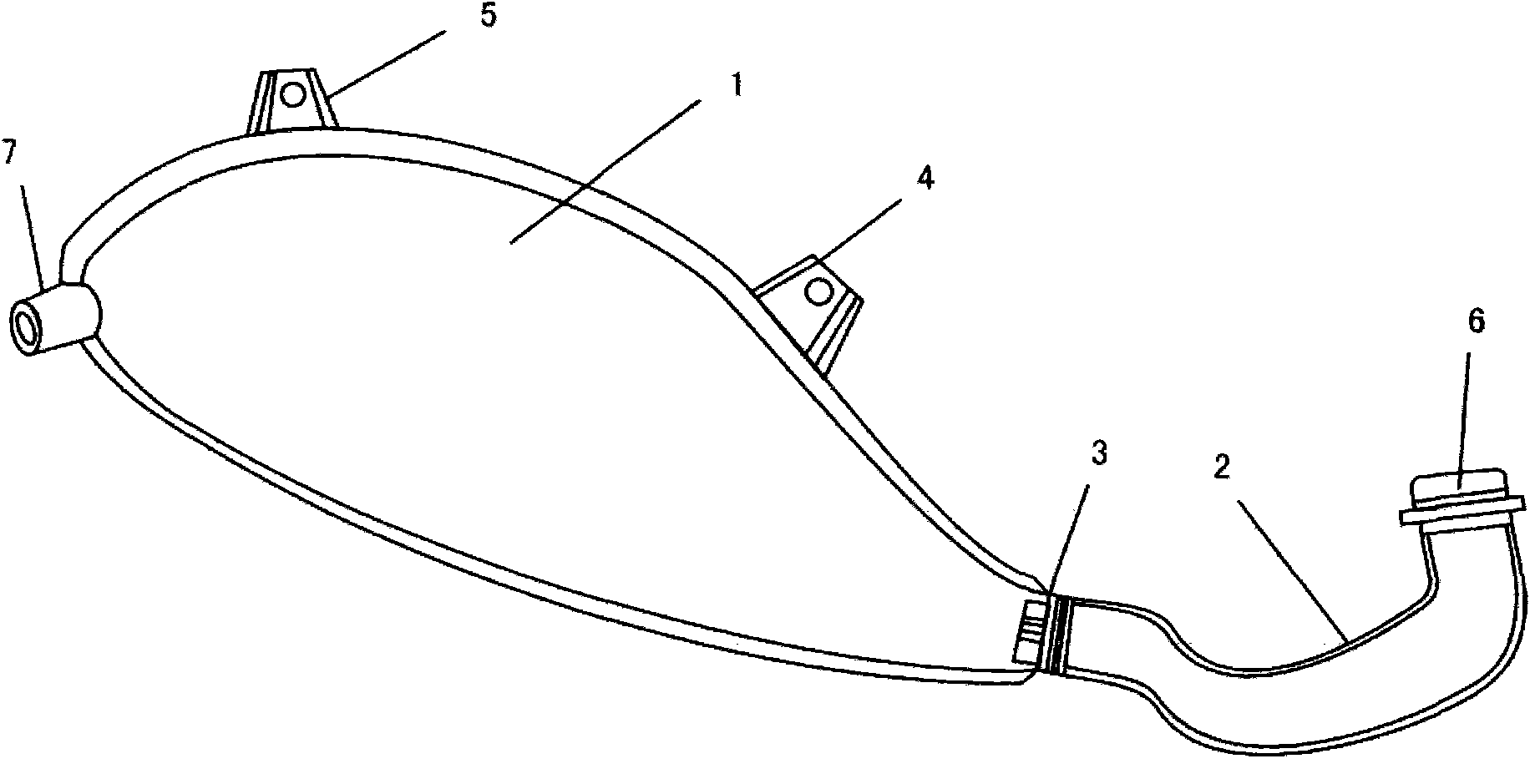

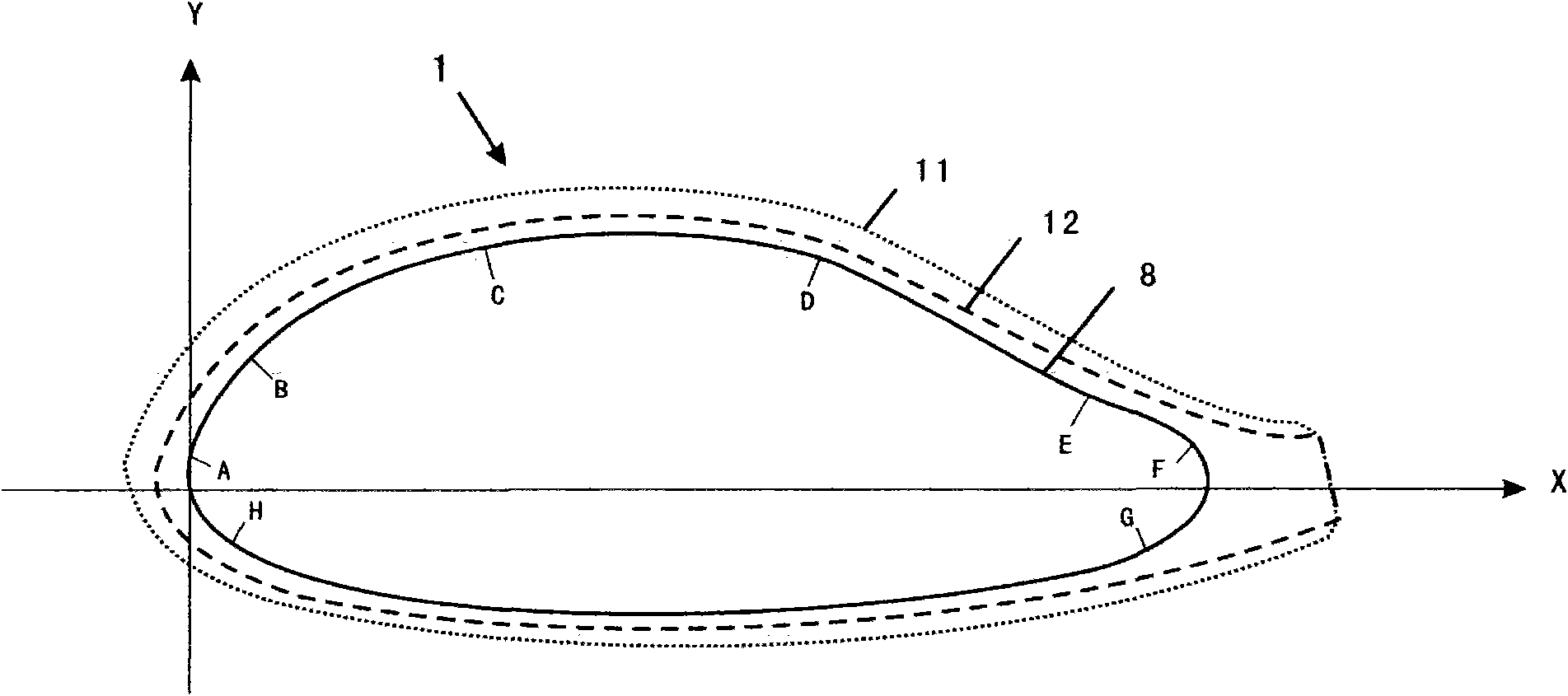

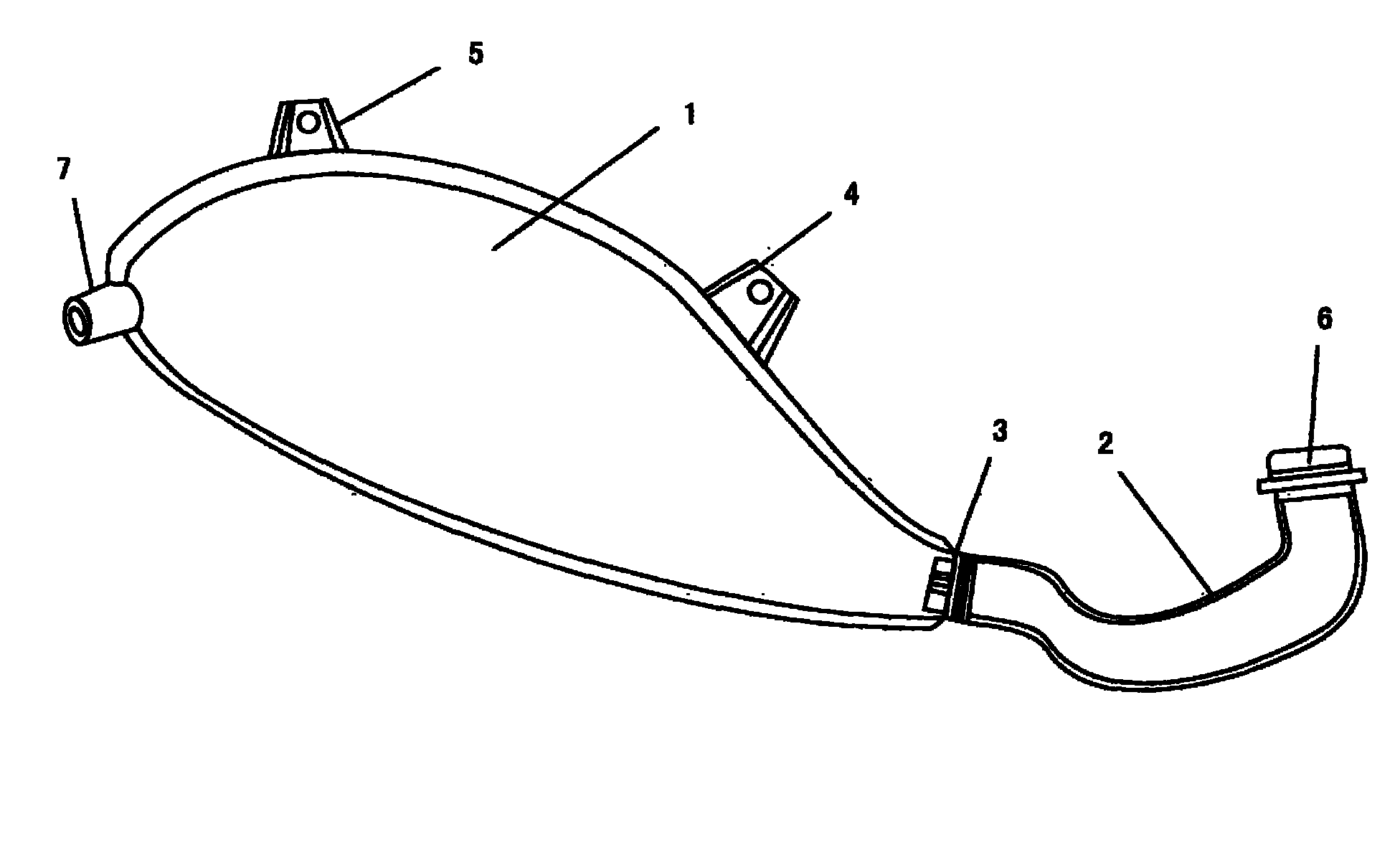

[0039] like figure 1 , figure 2 Shown, implement a kind of manufacturing process of muffler, described process comprises steps:

[0040] ①. This is the initial step. First, assemble and weld the outer bushing ring A of the inner muffler tube into an inner muffler tube assembly;

[0041] ②, then put the glass wool of the inner muffler tube inside the outer muffler tube, and then put the inner muffler tube assembly into it to assemble the outer muffler tube sub-assembly;

[0042] ③ Next, place the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com