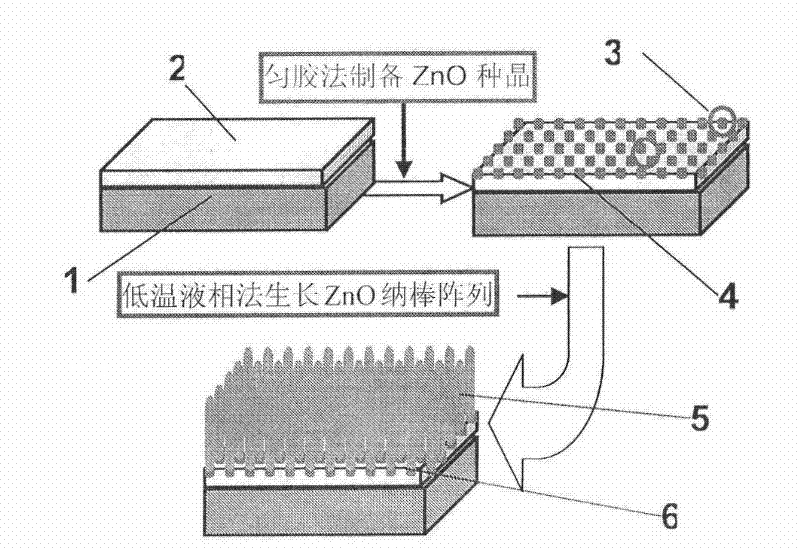

Preparation process for growing zinc oxide nanorod arrays by two-step method

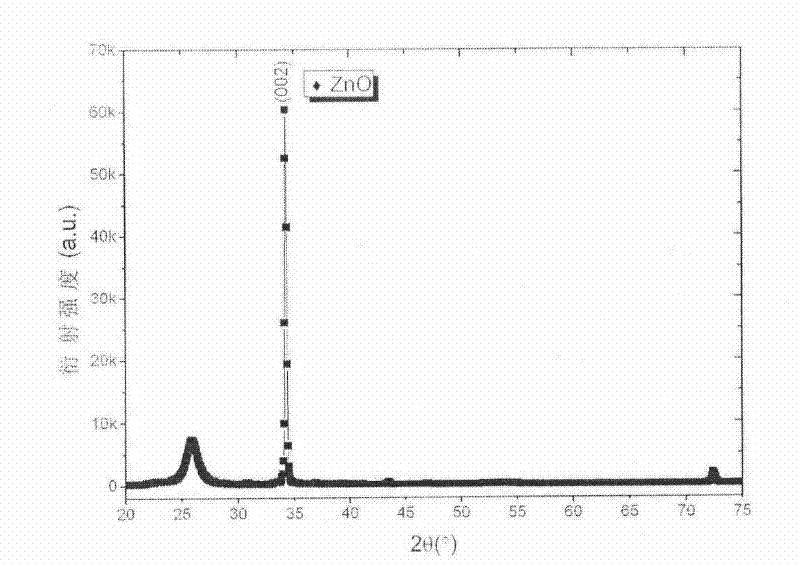

A zinc oxide nanorod, a preparation process technology, applied in the directions of zinc oxide/zinc hydroxide, crystal growth, single crystal growth, etc., to achieve the effects of high crystallinity, good electron transport ability, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

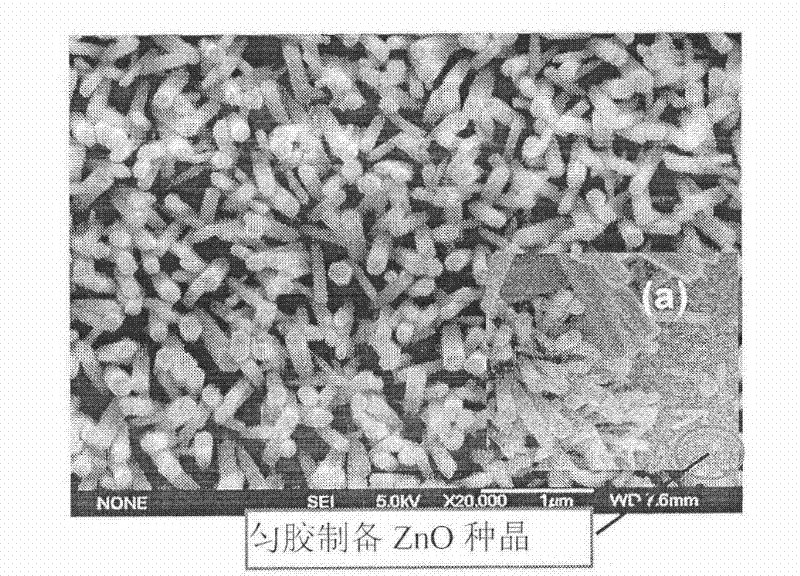

[0021] Embodiment: The preparation process of ZNRs with good growth density and orientation is as follows:

[0022] 1. Select the indium tin oxide conductive polyester film with a thickness of 0.25mm and good conductivity and cut it into the required size, wash it with absolute ethanol and dry it for later use;

[0023] 2. Under the condition of 60℃ water bath, slowly add 0.03M sodium hydroxide ethanol solution to 0.01M zinc acetate dihydrate ethanol solution, and form ZnO crystal nucleus colloid after stirring for 2 hours;

[0024] 3. Spin-coat the prepared ZnO crystal nucleus colloid on the cleaned and dried indium tin oxide conductive polyester film with a coater to pre-prepare the ZnO seed crystal;

[0025] 4. Set the speed of the homogenizer to 500r / min, spin-coat 2 layers of ZnO seed crystals, control the interlayer drying temperature to 45°C, and the drying time to 10min, then dry it for use;

[0026] 5. Growth of ZNRs: In 200mL of deionized water, add about 3g (0.05M)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com