Emulsified asphalt and preparation method thereof

A technology for emulsified asphalt and a manufacturing method, which is applied to building components, building insulation materials, buildings, etc., can solve the problems affecting the quality of cement emulsified asphalt mortar, narrow temperature adaptation range, and short working time, and achieves long working time and high temperature. Good adaptability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

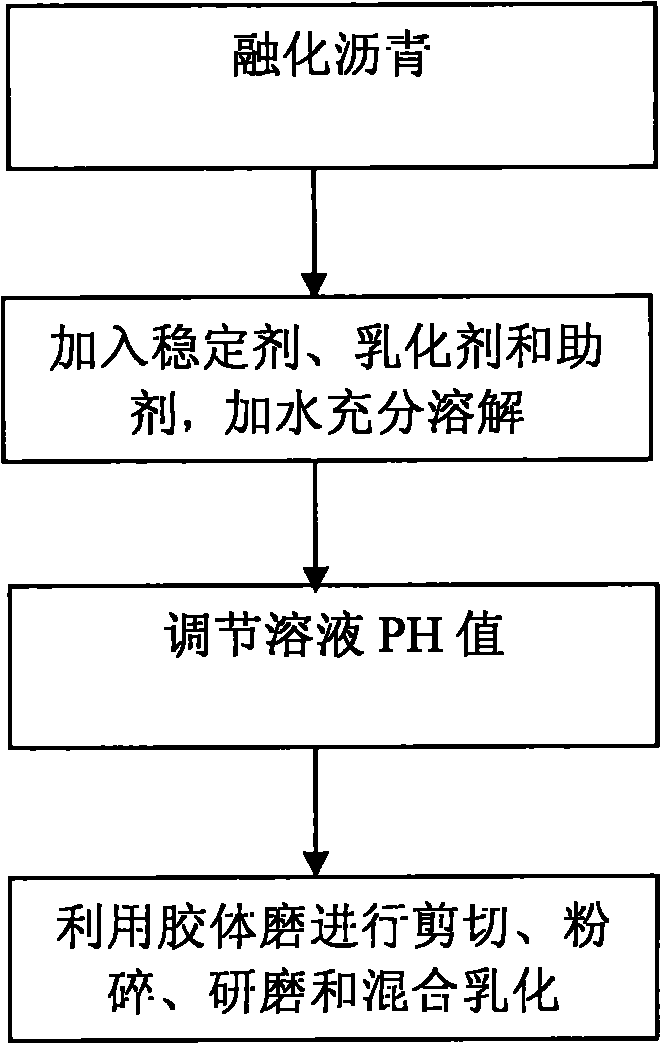

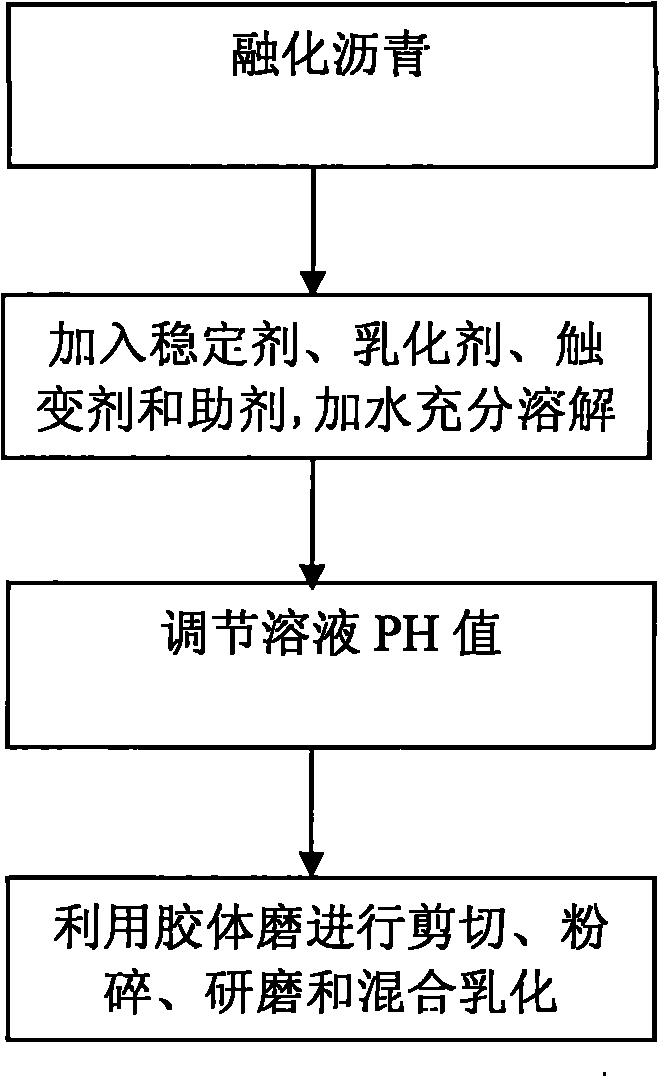

Method used

Image

Examples

Embodiment 1

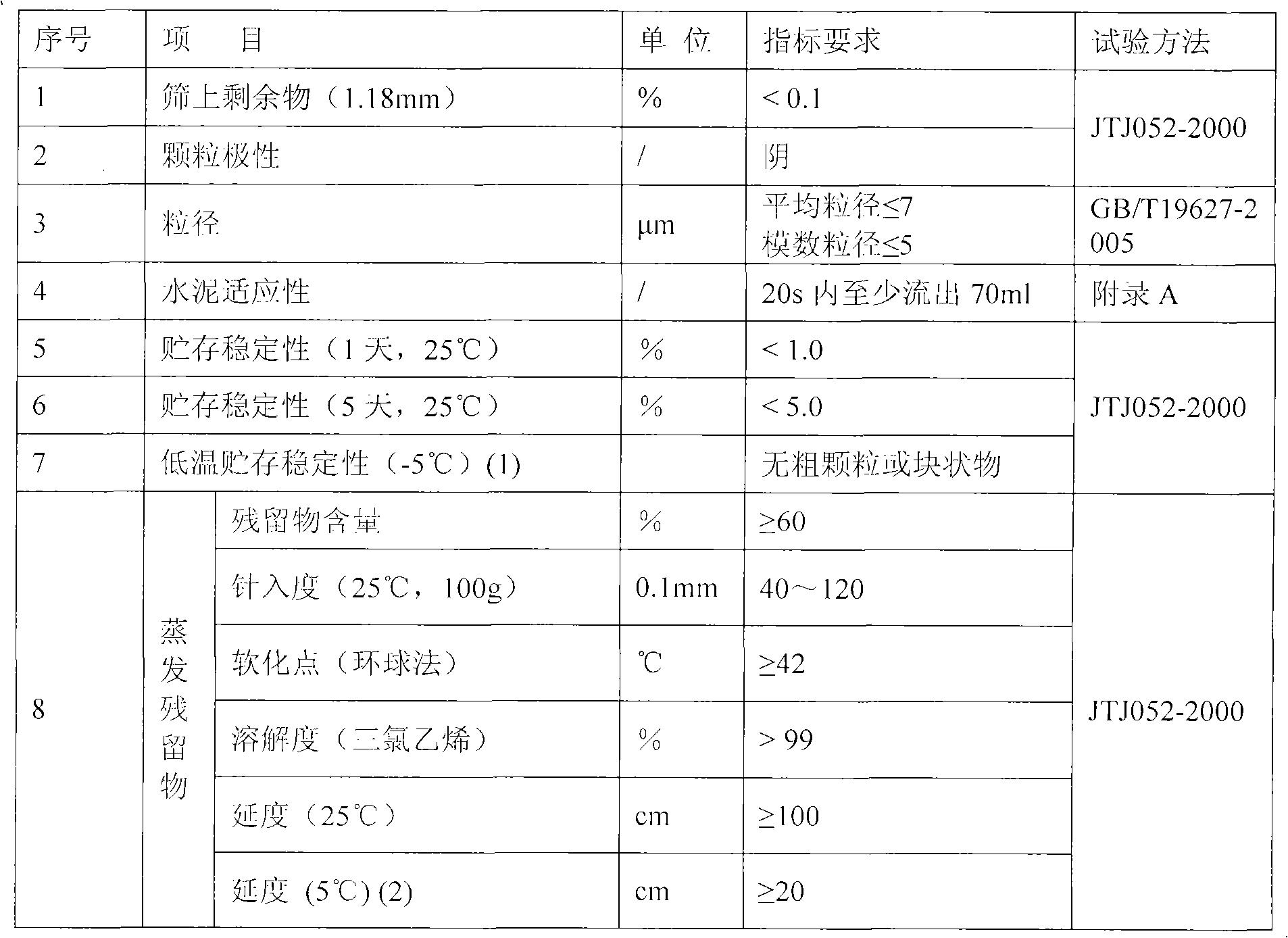

[0031] The emulsified asphalt provided in this example is No. 90 heavy traffic road asphalt, fatty acid sulfoalkyl ester anionic emulsifier, alkylphenol polyoxyethylene ether nonionic emulsifier, lauryl amidopropyl betaine amphoteric Ionic emulsifier, polyether and cellulose compound stabilizer, water-soluble silica thixotropic agent, the composition of which is shown in Table 3. The emulsified asphalt prepared in this example has good thixotropy, and the prepared mortar has good temperature adaptability, no subsidence, no layering and segregation after the mortar is cured, and is suitable for low temperature construction. The preparation steps are as follows:

[0032] ① Turn on the steam heating system, heat the No. 90 heavy traffic road asphalt to 130°C-160°C with the coil heating system in the ground tank to melt, use the pump to pump the asphalt to the batching tank, and heat the asphalt with the stated ratio to the batching tank for batching The tank is equipped with ste...

Embodiment 2

[0036] The emulsified asphalt provided by this example, the adopted asphalt is No. 90 heavy traffic road asphalt, lignosulfonate anionic emulsifier, cellulose stabilizer, water-soluble silica thixotropic agent, its composition is as shown in Table 3 shown. The emulsified asphalt prepared in this example is suitable for construction at room temperature. The preparation steps are as follows:

[0037]① Turn on the steam heating system, heat the No. 90 heavy traffic road asphalt to 130°C-160°C with the coil heating system in the ground tank to melt, use the pump to pump the asphalt to the batching tank, and heat the asphalt with the stated ratio to the batching tank for batching The tank is equipped with steam heating equipment, the temperature control parameters are set through the PLC control system, and the asphalt temperature is controlled at 130±5°C by controlling the opening of the steam valve, and the stirring is started;

[0038] ②Put the cellulose stabilizer, water-solu...

Embodiment 3

[0041] The emulsified asphalt provided in this example is No. 90 heavy traffic road asphalt, lignosulfonate anionic emulsifier, lauryl amidopropyl betaine and amino acid type zwitterionic emulsifier, cellulose stabilizer , whose composition is shown in Table 3. The emulsified asphalt prepared in this example is suitable for construction at room temperature. The preparation steps are as follows: the emulsified asphalt has good storage stability, and the prepared mortar has good fluidity and no settlement. The preparation steps are as follows:

[0042] ① Turn on the steam heating system, heat the No. 90 heavy traffic road asphalt to 130°C-160°C with the coil heating system in the ground tank to melt, use the pump to pump the asphalt to the batching tank, and heat the asphalt with the stated ratio to the batching tank for batching The tank is equipped with steam heating equipment, the temperature control parameters are set through the PLC control system, and the asphalt tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com