Real-time deviation correcting method for precise cutting process of diamond wire saw

A diamond wire saw and precision cutting technology, used in stone processing tools, stone processing equipment, fine working devices, etc., can solve problems such as deviation, and achieve the effect of fast deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

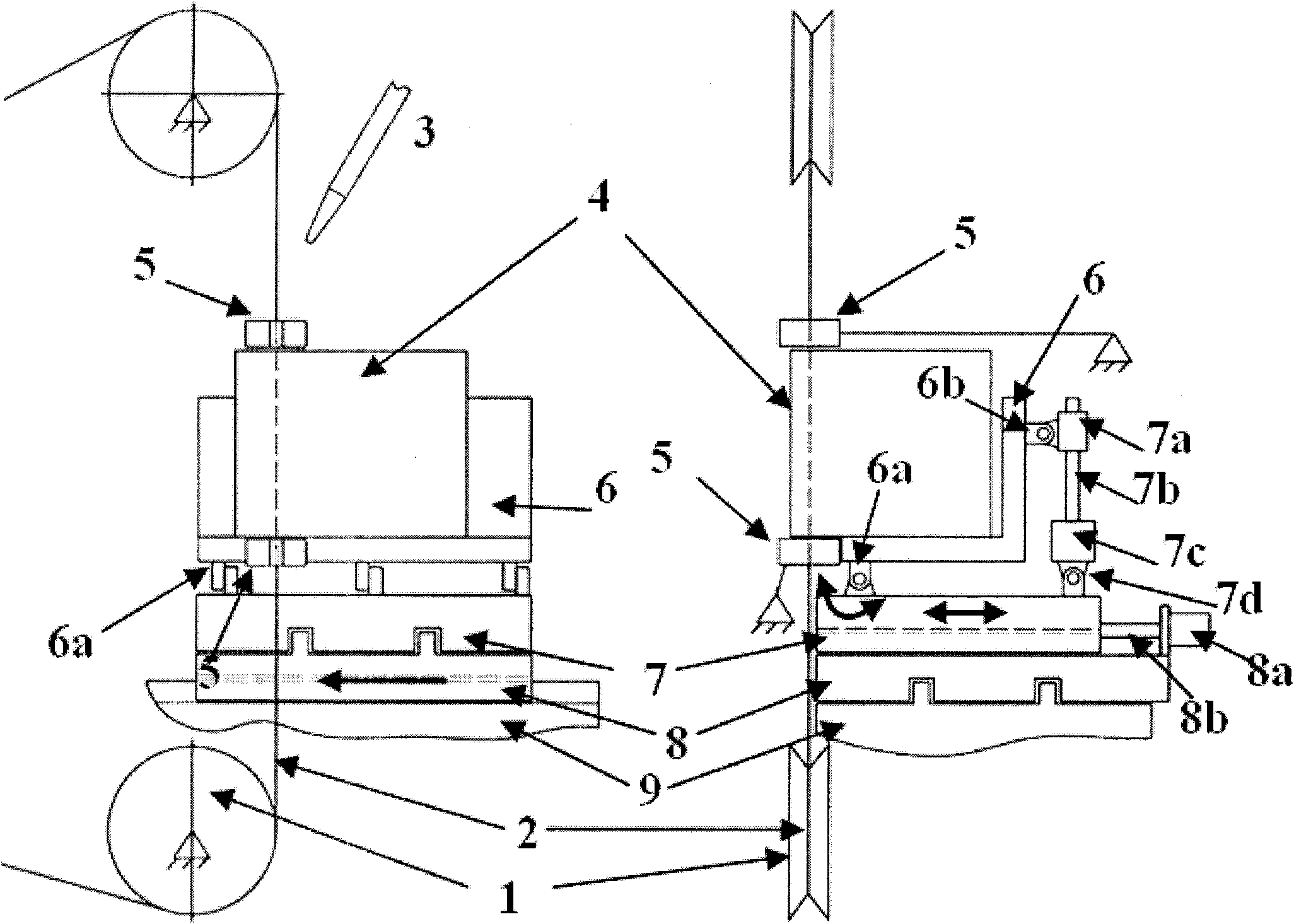

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings, and the specific implementation steps are as follows.

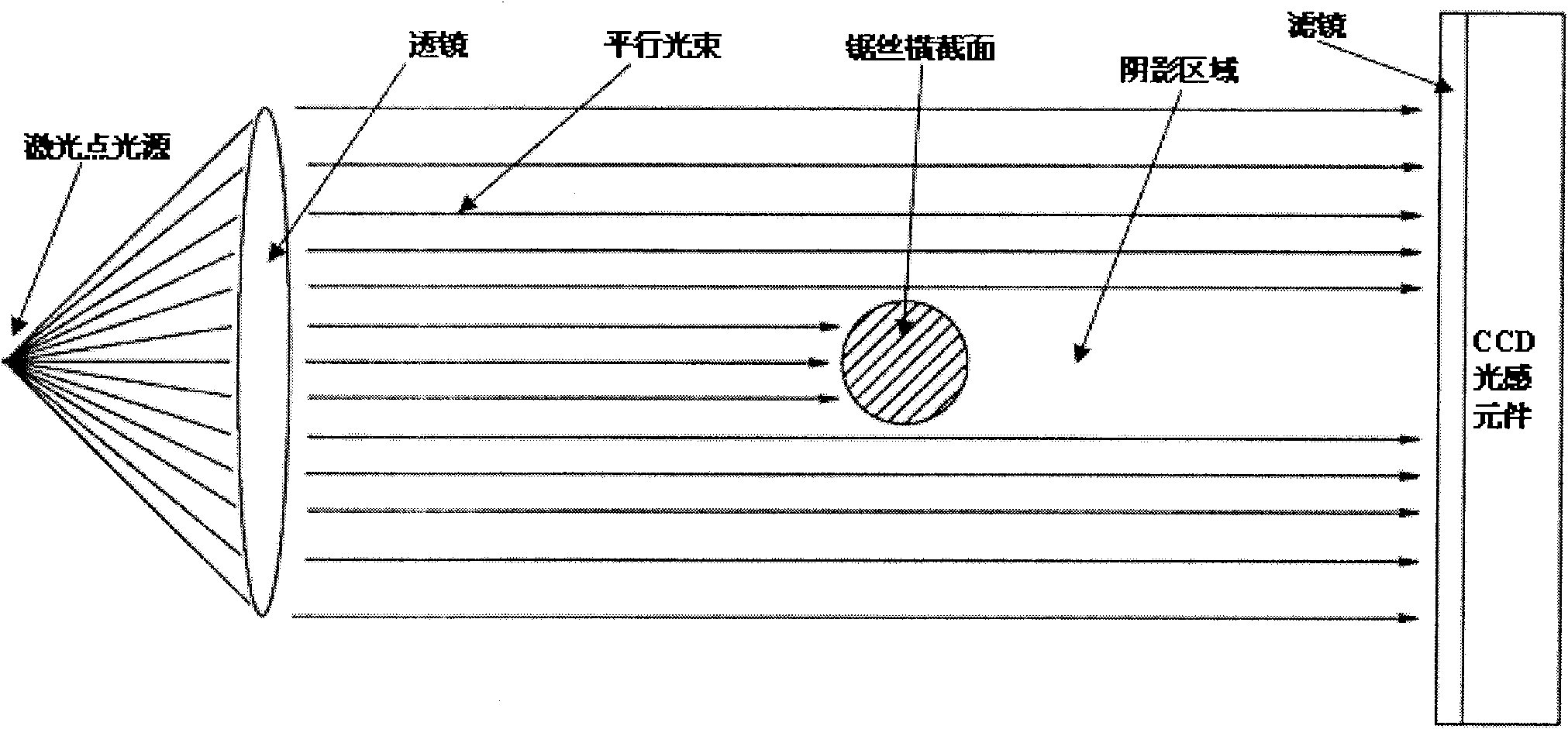

[0033] Step 1. First complete the workpiece clamping, wire saw tool setting, place two CCD photoelectric sensors on the upper and lower parts of the workpiece, and make them as close as possible to the workpiece, so that the wire saw just passes through the center of the CCD. At this time, the computer control system will The position of the straight wire saw that is not in contact with the workpiece is recorded by the CCD photoelectric sensor, which is used to characterize the initial cutting surface position of the workpiece.

[0034] Step 2. Start cutting, and the CCD starts to detect the deviation of the wire saw in real time.

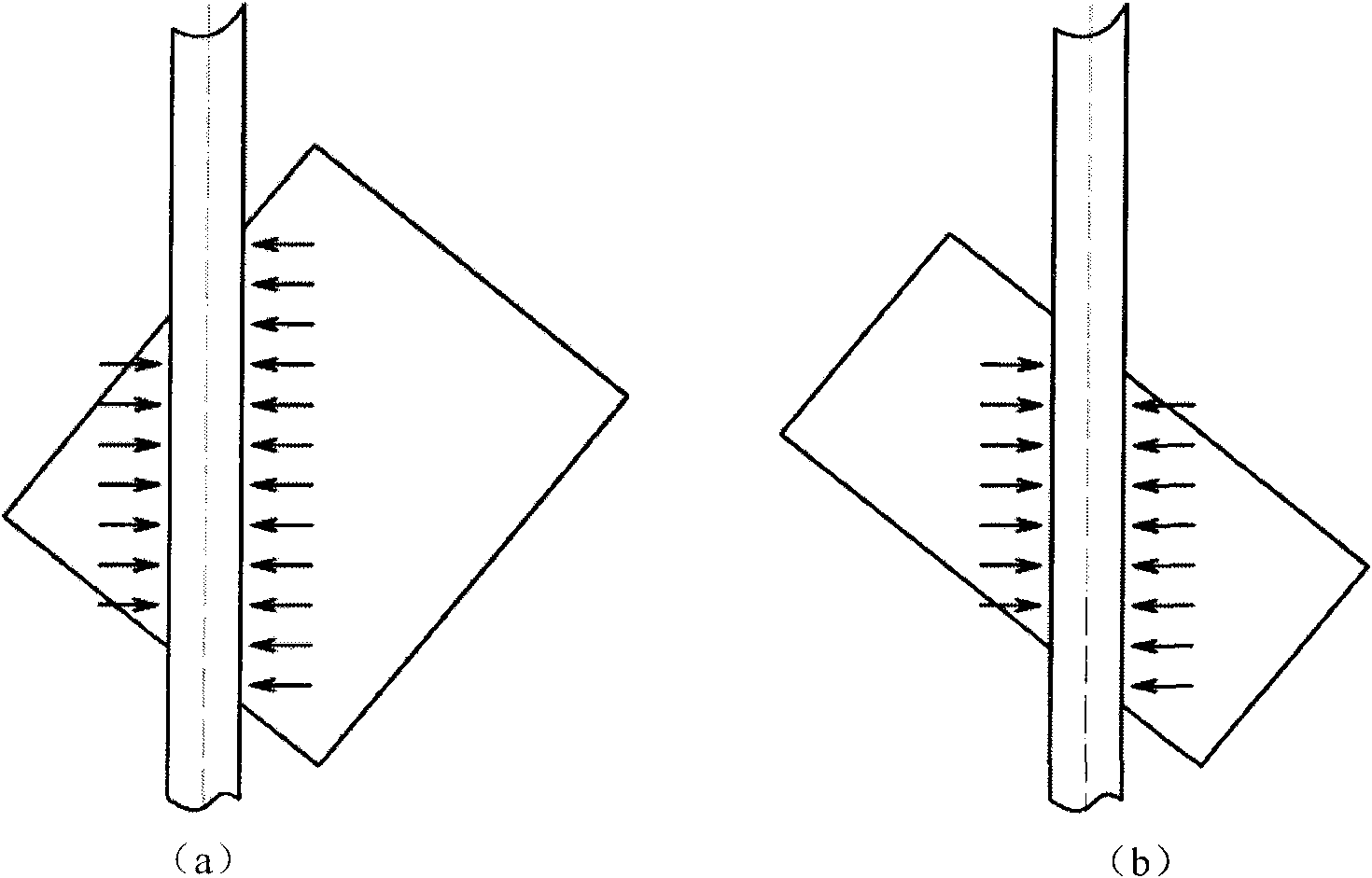

[0035] Step 3. Deviation correction strategy. When one of the CCDs detects the deviation of the wire saw, it will judge whether the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com