Sn-58Bi lead-free solder reinforced by carbon nano tube and preparation method thereof

A sn-58bi, carbon nanotube technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of Sn-58Bi alloy plastic reduction, affecting the performance of welded joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific Embodiment 1: In this embodiment, carbon nanotube reinforced Sn-58Bi lead-free solder is ball milled with eutectic Sn-58Bi alloy powder and carbon nanotubes under the protection of argon, and then the mixture is smelted by adding flux and air-cooled Made, wherein the mass fraction of carbon nanotubes in the mixture of eutectic Sn-58Bi alloy powder and carbon nanotubes after ball milling is 0.01% to 0.1%, and the mixture of eutectic Sn-58Bi alloy powder and carbon nanotubes after ball milling and auxiliary The mass ratio of flux is 8:2. The mass fraction of Sn in the eutectic Sn-58Bi alloy powder is 42%, and the mass fraction of Bi is 58%.

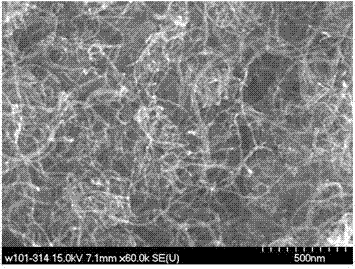

[0011] The carbon nanotubes used in this embodiment are multi-walled carbon nanotubes.

[0012] The carbon nanotubes (FloTube9000) used in this embodiment are provided by Cnano Co., Ltd., and the ball mill used for ball milling is a QM-1SP planetary ball mill produced by Nanjing University Instrument Factory.

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the particle size of the eutectic Sn-58Bi alloy powder is 25 μm˜75 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the flux is Flux55. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com