Method for preparing protein chip by in-situ synthesis

A protein chip, in-situ synthesis technology, which is applied in the process of producing decorative surface effects, manufacturing microstructure devices, decorative arts, etc., can solve the problem of insufficient repeatability of experimental results, difficult to control experimental conditions, and complicated production processes problems, achieve high-throughput real-time detection and analysis, avoid surface non-specific adsorption, and avoid direct contact.

Inactive Publication Date: 2010-08-25

WUXI ZHONGMEI YIXIN BIOTECH

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The first is the cost issue. The current protein chip production process is quite cumbersome and complicated, and the signal detection also requires special and expensive equipment (such as seldi-tof-ms); Small changes may cause differences in the final results, and the experimental conditions are not easy to control, making the repeatability of the experimental results relatively insufficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

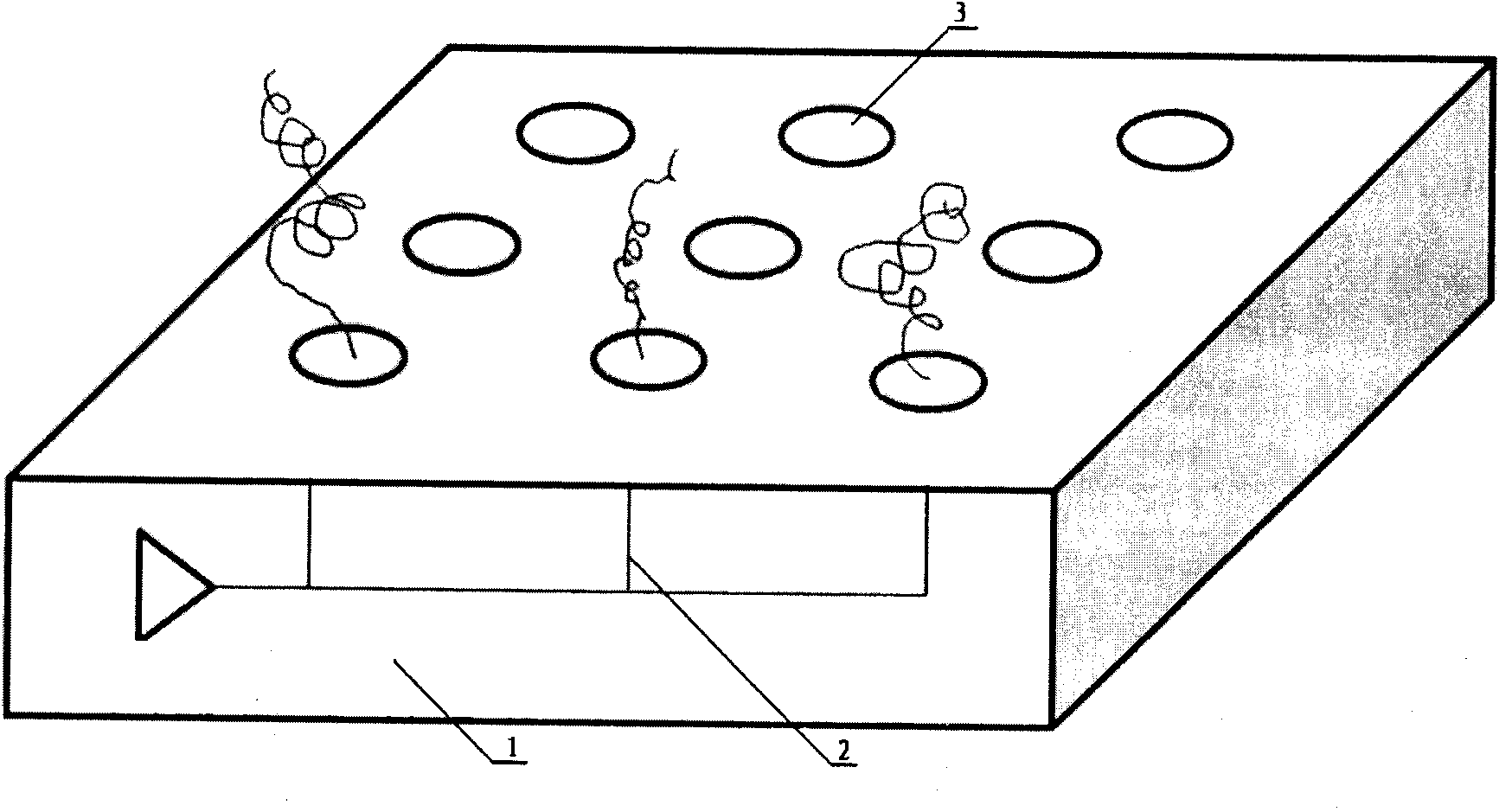

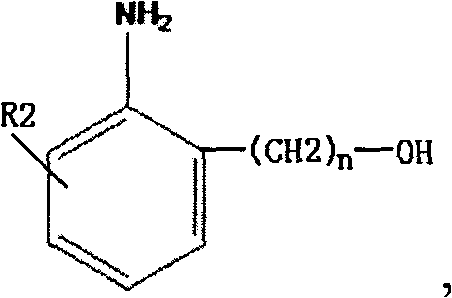

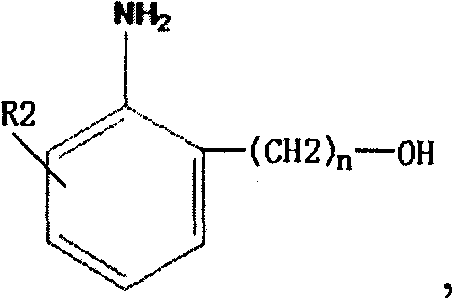

In order to solve the problem, which troubles academic circles for a long time, about how to permanently bond protein molecules to the metal actively and fixe the protein molecules on the metallic surface of any detector or any independent addressing electrode in place at one step, the invention provides a method for preparing a protein chip. The method comprises the following steps of: by adopting an in-situ electrochemical combination synthesis method and independent addressing microelectrode array technique, making an aniline derivative monomer containing bioactive units and anilines in solution copolymerized on an electrode in a mode of active free radical polymerization, generating an electrode coverings which is bioactive and electrically conductive on the electrode in situ at one step, and under bionic conditions, making avidins connected with various proteins tightly bonded with the e electrode coverings to prepare the protein chip. The method has the advantages of laying a foundation for an unmarked analysis method, truly making mass production of protein chips possible, providing the possibility for the automatic production of the protein chips at the operation level forthe first time, along with high reproducibility.

Description

A method for preparing protein chips by in situ synthesis technical field The invention relates to a method for preparing a protein chip, in particular to a microelectrode array technology using an in-situ electrochemical combinatorial synthesis (combinatorial synthesis) method and independent addressing to make aniline derivatives with biologically active units single The body is copolymerized with aniline in the solution on the electrode by living free radical polymerization, and a biologically active and conductive electrode covering is directly formed on the electrode in situ in one step, and the avidin with a variety of proteins is connected to it under biomimetic conditions. A method for making a protein chip by strong binding. Background technique Biochip technology is a high-tech developed rapidly in the field of life science since the 1990s. It mainly refers to the construction of a miniature biochemical analysis system on the surface of a solid chip through micr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/68G01N27/327B81C1/00

Inventor 王巍

Owner WUXI ZHONGMEI YIXIN BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com