Self-adhesive fabric internally reinforced thermoplastic polyolefin composite waterproof roll

A technology of thermoplastic polyolefin and enhanced thermoplasticity, which is applied in fabrics, roofs using flexible materials, and film/sheet adhesives, etc. The flatness of the coil is not good, etc., to achieve the effect of strong adhesion, simple processing and simple construction

Active Publication Date: 2010-08-25

TANGSHAN DESHENG WATERPROOF

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It solves the problems of low elongation, poor dimensional stability, poor flatness of the membrane, weak adhesion with self-adhesive adhesive and poor weather resistance of the prior art waterproof membrane

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

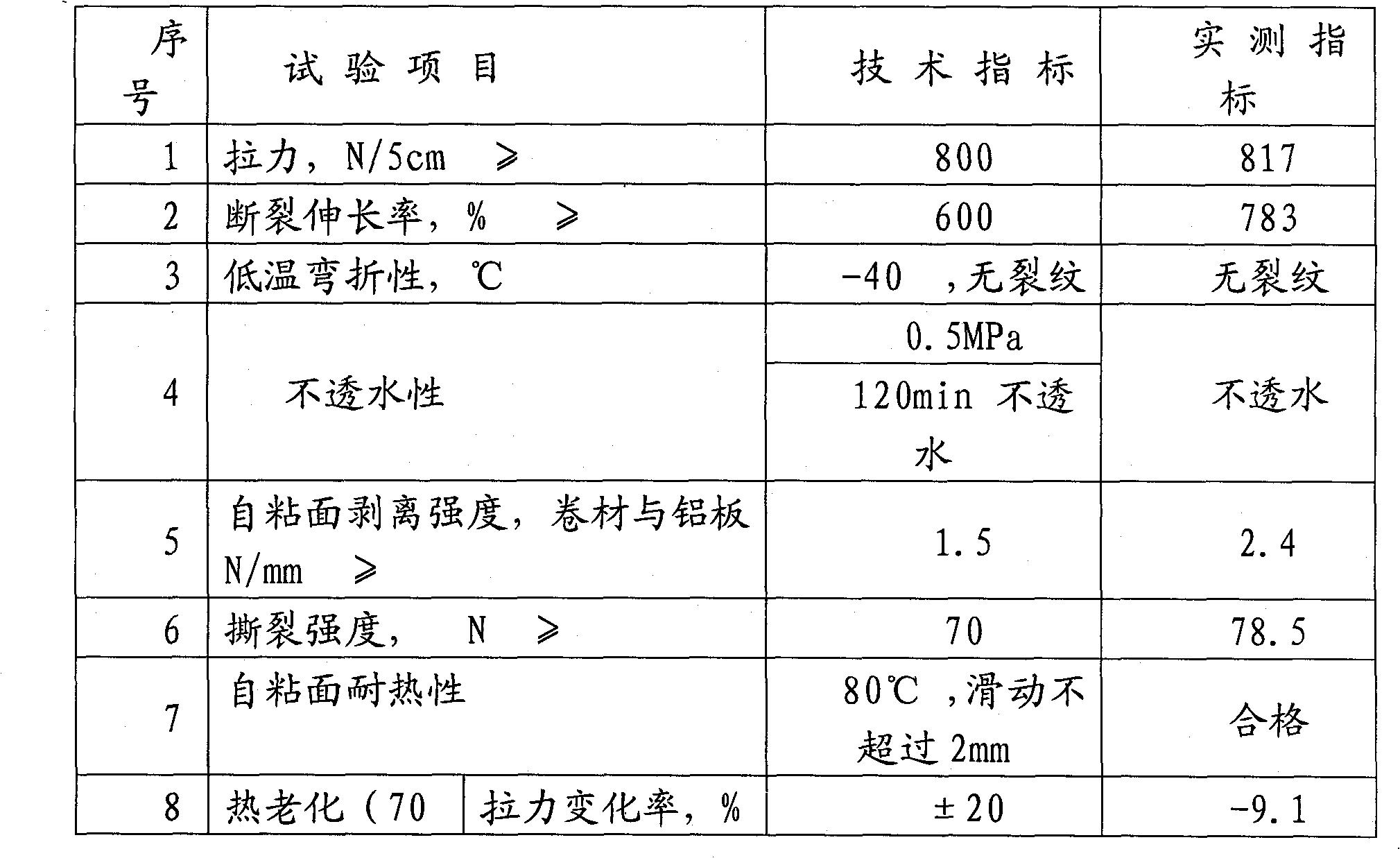

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a self-adhesive fabric internally reinforced thermoplastic polyolefin composite waterproof roll, which at least comprises a fabric internally reinforced thermoplastic polyolefin layer, a functional transition layer and a self-adhesive layer, wherein the fabric internally reinforced thermoplastic polyolefin layer is formed by combining two thermoplastic polyolefin layers with one fabric reinforcing layer. The thermoplastic polyolefin layer mainly comprises first ingredient thermoplastic polyolefin, second ingredient thermoplastic polyolefin, a filler, a coupling agent, a light screener, an antioxidant and a light stabilizer. In the invention, the advantages of environmental friendliness, simple processing, low-temperature performance, capability of welding, whether resistance and the like of the TPO roll are combined with the advantages of convenient construction, high substrate bond strength, adhering completeness, reliable lapped side welding, no 'water movement between layers' and the like of self-adhered membranes. The waterproof roll has the advantages of high strength, high elongation, high low-temperature performance, high whether resistance, high sunlight reflectivity, high roll smoothness, strong bonding force of the self-adhesive, convenient construction and the like and thus is an advanced waterproof roll.

Description

technical field The invention relates to a waterproof coiled material. Specifically, it relates to a self-adhesive fabric internally reinforced thermoplastic polyolefin composite waterproof coiled material. Background technique Thermoplastic polyolefin (TPO for short, the same below) material is a material containing only carbon and hydrogen. It has the advantages of environmental friendliness, easy processing, good low temperature performance, weldability, and good weather resistance. It is widely used in Europe, America and other countries. The single-layer roof system has been widely used, and it is increasing year by year. The single-layer roof system is generally suitable for large-scale roofs such as supermarkets and factories. However, most domestic residential buildings have relatively small roof areas at this stage, so this system is not suitable. The single-layer roof system is generally constructed by mechanical fixing and hot air welding. The advantages of thi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B1/64B32B27/06B32B27/32B32B15/085B32B15/04C08L23/16C08L23/08C08L23/06C08L23/12C09J7/29

CPCB32B27/18B32B27/12B32B27/32B32B15/08B32B27/20E04D5/10E04B1/66E04D13/1475B32B11/08E04D13/1407C09J2423/006E04D5/06E04B1/644B32B27/322E04D12/002C09J2400/263E04D5/04C09J7/0296B32B5/024B32B7/12B32B15/20B32B27/327B32B2250/40B32B2262/0261B32B2262/0276B32B2264/102B32B2264/104B32B2307/306B32B2307/416B32B2307/50B32B2307/538B32B2307/54B32B2307/546B32B2307/5825B32B2307/712B32B2307/73B32B2307/732B32B2307/734B32B2419/00B32B2607/00C09J7/29Y10T442/183Y10T428/249921

Inventor 李德生黄鹭鹭

Owner TANGSHAN DESHENG WATERPROOF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com