Model for optimally controlling heating system of large walking beam type heating furnace plate blank

An optimized control and slab heating technology, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve problems such as the heating system that has not yet established a scientific calculation method, achieve great social value, increase furnace temperature, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

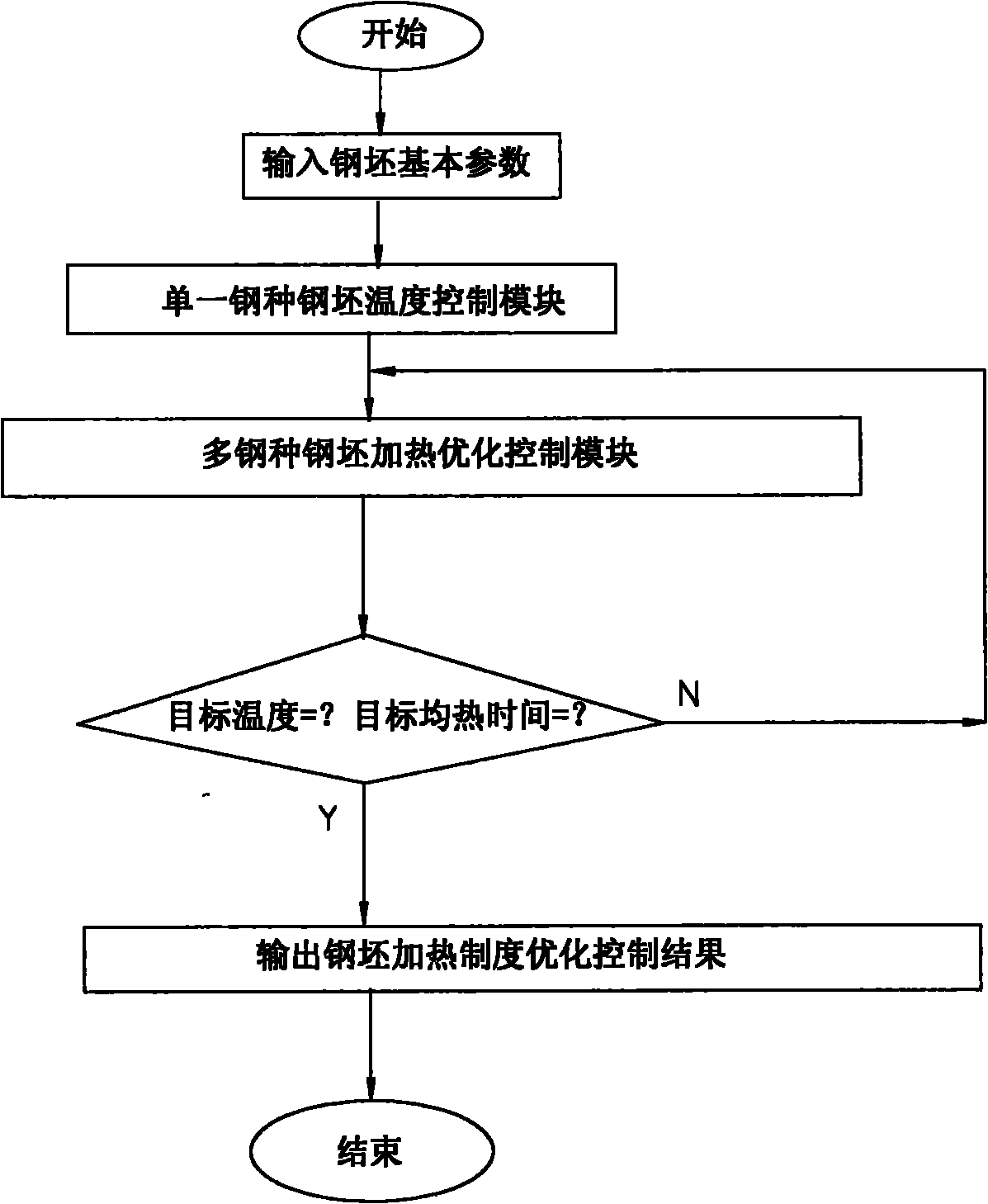

[0010] Using the steel grade heating system design and the mixed heating design model, the heating time of the billet in the furnace and the corresponding temperature control strategy of each section of the furnace are optimized under different steel grades and different furnace entry temperatures. The model can be used to predict the furnace temperature control of each section of the heating furnace, the heating time and the variation law of the slab heating temperature during the heating process under the condition of single steel grade or different steel grades or different steel grade slab entering furnace temperature and slab mixed loading. For example: optimize SPHC, Q345, ultra-low carbon steel and other steel types, the slab heating time in the furnace and the heating temperature of each section under different furnace entry temperatures, to provide a basis for improving the current billet hot charging and hot delivery system.

[0011] The key technology to optimize and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com