Method for preparing carbon dioxide capture material with coal gangue and polyethylene

A polyethyleneimine, carbon dioxide technology, applied in chemical instruments and methods, separation methods, inorganic chemistry and other directions, can solve problems such as insufficient strength, difficulty in effective separation, limitations, etc., and achieve good heat resistance, good capture effect, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

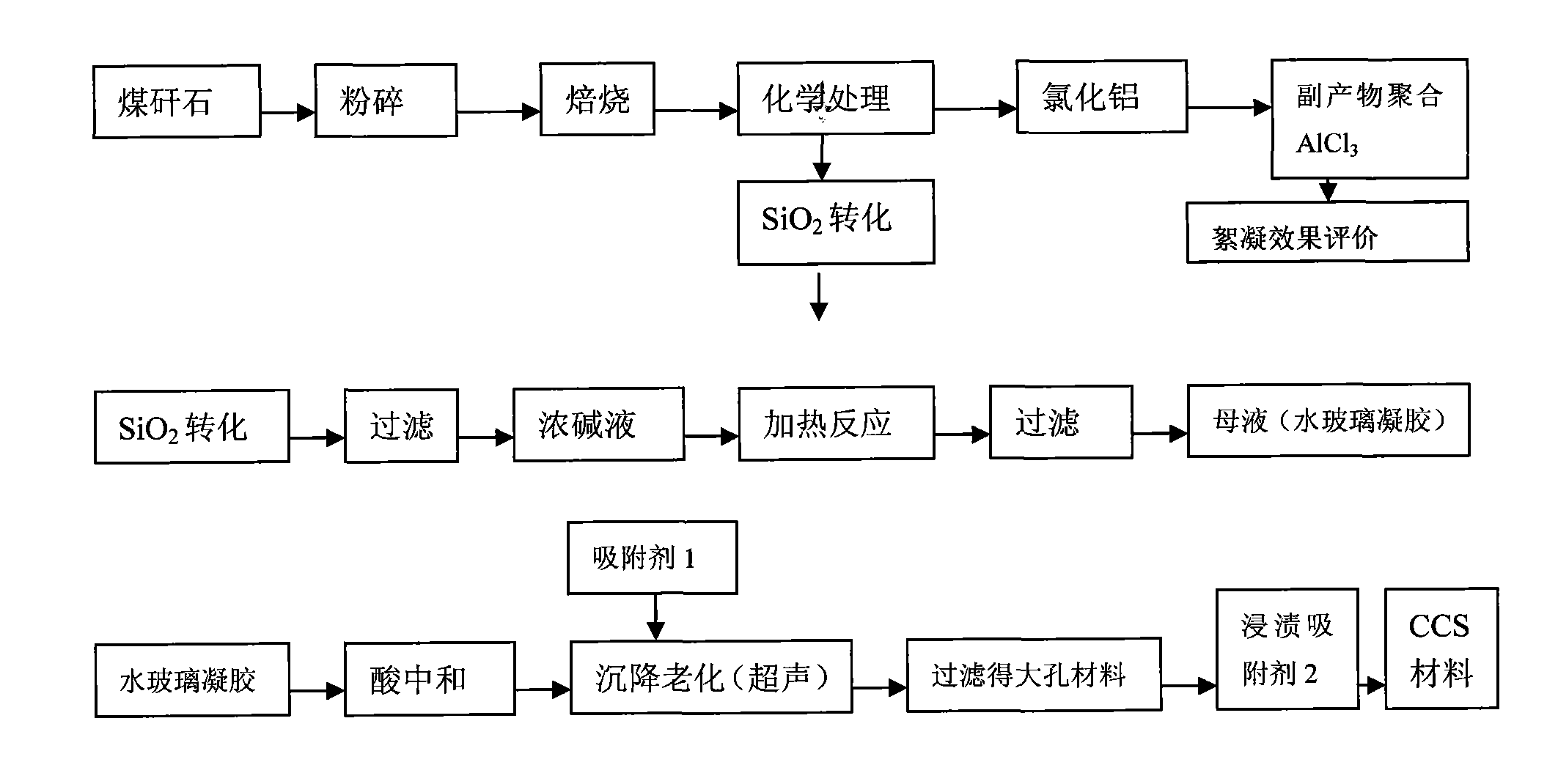

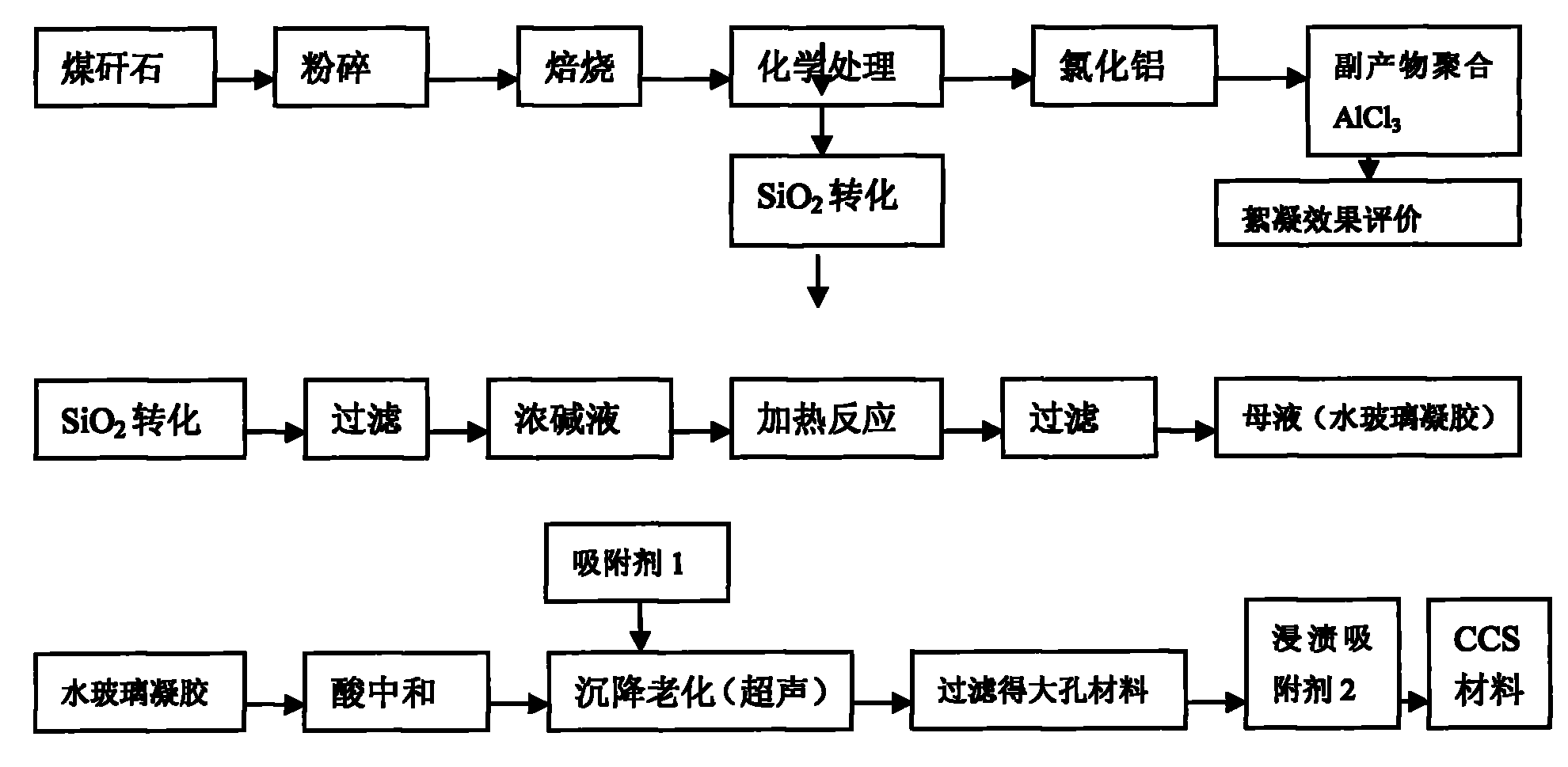

Method used

Image

Examples

Embodiment 1

[0012] Example 1, take a certain amount of coal gangue and crush it to below 40 mesh, roast it at a constant temperature of 850°C to 950°C for 6-8 hours, and then dissolve the roasted solid minerals with 15% HCl solution for 2 hours. Vacuum filtration under reduced pressure to obtain the mother liquor as an aluminum salt solution. Filter to obtain the unreacted mineral matter containing silicon dioxide, then use 40% sodium hydroxide solution to alkalinize the unreacted matter, the amount of silicon dioxide material in the mineral and the amount molar ratio of sodium hydroxide material is 1: 4. The reaction time is 6 hours, the reaction temperature is 100°C, and the silicate solution is obtained by suction filtration under reduced pressure. Use a 3% polyethyleneimine hydrochloric acid solution with a hydrochloric acid concentration of 10-15% to react with the silicate solution to produce precipitation , the mass ratio of polyethyleneimine to silicon dioxide is 1:4. Ultrasonic ...

Embodiment 2

[0013] Embodiment 2, get a certain amount of coal gangue, through 850 ℃~950 ℃, constant temperature 6-8 hour roasting, then the solid mineral matter after roasting is dissolved with 15% HCl solution, dissolving time 2h, through reduced pressure suction filtration, The mother liquor is obtained as aluminum salt solution. Filter to obtain the unreacted mineral matter containing silicon dioxide, then use 40% sodium hydroxide solution to alkalinize the unreacted matter, the amount of silicon dioxide material in the mineral and the amount molar ratio of sodium hydroxide material is 1: 4. The reaction time is 6 hours, the reaction temperature is 100°C, and the silicate solution is obtained by suction filtration under reduced pressure. The silicate solution is first precipitated and aged with 10-15% hydrochloric acid solution. The mass ratio of polyethyleneimine to silicon dioxide is 1:3. At the same time, ultrasonic treatment was used to prepare mesoporous particles, and then impre...

Embodiment 3

[0014] Example 3, take a certain amount of coal gangue and crush it to below 40 mesh, roast it at a constant temperature of 6-8 hours at 850°C to 950°C, then dissolve the roasted solid minerals with 15% HCl solution for 2 hours, Vacuum filtration under reduced pressure to obtain the mother liquor as an aluminum salt solution. Filter to obtain the unreacted mineral matter containing silicon dioxide, then use 40% sodium hydroxide solution to alkalinize the unreacted matter, the amount of silicon dioxide material in the mineral and the amount molar ratio of sodium hydroxide material is 1: 4. The reaction time is 6 hours, the reaction temperature is 100°C, and the silicate solution is obtained by vacuum filtration, and the hydrochloric acid solution containing 5% polyethyleneimine is used, and the concentration of hydrochloric acid is 10-15%, and the silicate solution is mixed and reacted to produce precipitation , the mass ratio of polyethyleneimine to silicon dioxide is 1:5. Ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com