Pre-stress construction method of parallel steel stranded wire assembled cable in annular sealed steel pipe

A parallel steel strand and ring-closed technology, which is applied in the processing of building materials, structural elements, building components, etc., can solve the problem of meeting the operating space requirements of large tension jacks and tooling, and the difficulty of realizing the tension of the whole bundle of assembled cables , the small space at the end of the cable anchorage, etc., to achieve the effect of reducing the tensioning tooling, jack and its operating space, low requirements for cable length control, and good construction simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] 1) The cable is assembled with steel strands.

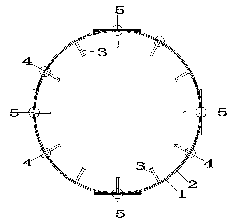

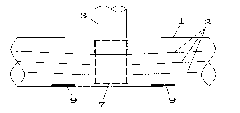

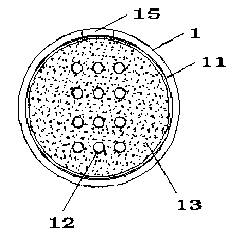

[0045]2) A one-way split wire diverter is installed at the inflection point of the circular steel pipe, and a two-way cross split wire diverter is arranged at the intersection of the cables inside the steel pipe. The steering gear is composed of an outer sleeve, a splitter plate, a guide tube and filling materials. Each guide tube corresponds to a steel strand, and each steel strand of the same bundle of assembled cables passes through the diverter through the tunnel in the guide tube. The guide tunnel of the diverter is arranged in a rectangular or approximately rectangular manner, which corresponds to the arrangement of the anchor plate holes and steel strands at the cable end. The two-way crossing split wire diverter corresponds to the crossed two bundles of assembled cables, the number of its guide holes is the sum of the number of steel strands of the two bundles of assembled cables, and the guide holes of the two bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com