Preparation method of Al-Doped ZnO film

A technology of aluminum-doped zinc oxide thin film, which is applied in the field of preparation of aluminum-doped zinc oxide thin film, can solve the problems of high cost, complex equipment, unsuitable for large-area preparation, etc., and achieve the effect of no need for high temperature, no need for vacuum equipment, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

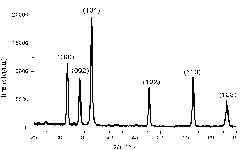

Embodiment 1

[0027] 500mg of AZO nanoparticles (20nm, where the aluminum content is 5%) were dispersed into a flask with 10ml of absolute ethanol, and the solution was ultrasonically treated for 15 minutes to obtain a uniformly dispersed solution of AZO; then 10mg of alkyl silane coupling was added agent and 10 mg 1-hydroxycyclohexyl phenyl ketone, and continued ultrasonic treatment for 2 hours; the surface-modified AZO nanoparticles were coated on the glass substrate by spin coating method, and irradiated with ultraviolet light with a wavelength of 254nm for 2min; Heat treatment at 200° C. for 4 hours in a nitrogen atmosphere to obtain an AZO film.

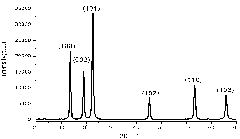

Embodiment 2

[0029] 1.5g of AZO nanoparticles (40nm, wherein the aluminum content is 20%) was dispersed in a flask with 10ml of absolute ethanol, and the solution was ultrasonically treated for 10 minutes to obtain a uniformly dispersed solution of AZO; then 15mg of vinyl silane was added. Joint agent and 5mg 1-hydroxycyclohexyl phenyl ketone. Continue to sonicate for 0.5 hours; use the spin coating method to coat the surface-modified AZO nanoparticles on the glass substrate, and irradiate with ultraviolet light with a wavelength of 254nm for 0.5min; finally heat treat at 200°C for 0.5 hours in a nitrogen atmosphere to obtain AZO film.

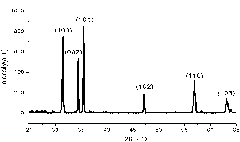

Embodiment 3

[0031] 3g AZO nanoparticles (30nm, wherein aluminum content is 15%) are dispersed in the flask that 10ml dehydrated alcohol is housed, the solution is sonicated for 20 minutes, obtain AZO homogeneously dispersed solution; Combined agent and 40mg of 2-hydroxy-methylphenylpropan-1-one, continue ultrasonic treatment for 4 hours; finally use the spin coating method to coat the surface-modified AZO nanoparticles on the glass substrate, and use a wavelength of 254nm UV light irradiation for 1 min; finally heat treatment at 200° C. for 4 hours in a hydrogen atmosphere to obtain an AZO film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com