Open-pipe zinc dispersing method

A diffusion method, zinc powder technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the troublesome process of vacuuming, sealing and opening tubes, is not suitable for mass continuous production, cannot be completely sealed, etc. problems, to achieve the effect of short production cycle, simple heat treatment equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

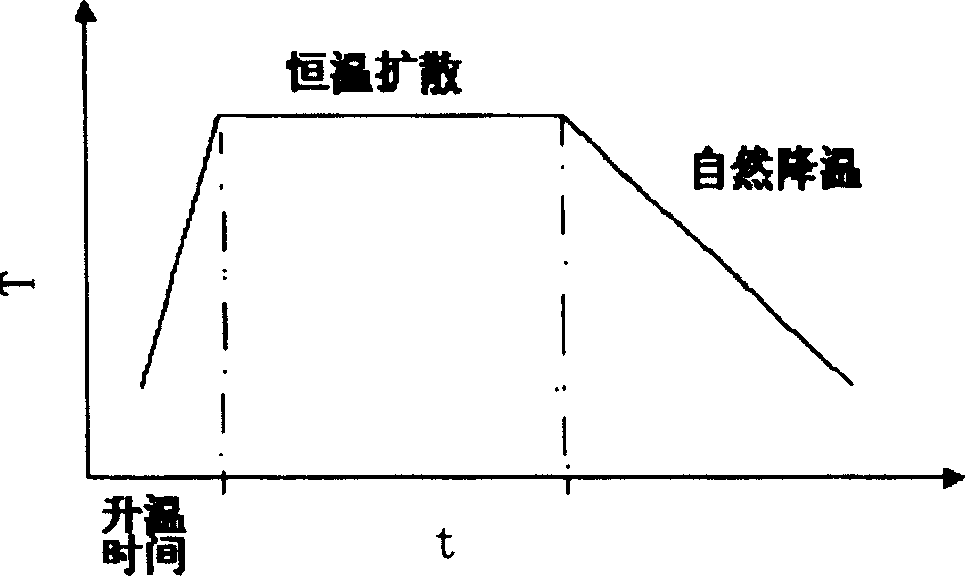

Embodiment 1

[0029] Grind 0.4g of zinc powder (the particle size of the zinc powder is like fine flour, with a purity of more than 99.99%), mix it into 0.4g of organic silica gel, and stir evenly to obtain a diffusion source. Coat a layer of diffusion source on a gallium arsenide sheet of any size, size, and shape, and use an old-fashioned gluing machine to spread the glue. The transformer can be adjusted from 0 to 50V, and the glue spreading time is about 45s, so that the zinc-containing organic silica gel is relatively Evenly distributed on the gallium arsenide sample with a thickness of 0.4mm, coated with organic silica gel on the sample after uniform glue, the thickness of the organic silica gel layer is 0.6mm, and then put it in a drying oven to dry until the glue is naturally solidified, then bake The drying temperature is 120°C. Diffusion is carried out in a rapid thermal annealing furnace with zinc-containing organic silica gel as the diffusion impurity source, nitrogen is used as ...

Embodiment 2

[0037] Similar to Example 1, the difference is that 0.4 g of zinc powder is ground and then mixed into 0.6 g of organic silica gel. Make the zinc-containing organic silica gel evenly distributed on the gallium arsenide sample with a thickness of 0.1mm, and coat the organic silica gel on the sample after uniform glue, the thickness of the organic silica gel layer is 0.1mm, and then put it in a drying oven to dry Dry until the glue solidifies naturally, and the drying temperature is 90°C.

[0038] Diffusion is carried out in a rapid thermal annealing furnace with zinc-containing organic silica gel as the diffusion impurity source, nitrogen is used as the protective gas, and the gas flow rate is 5ml / m 3 , for diffusion, the diffusion temperature is 550-580°C, and the diffusion time is 10-15min;

[0039] Wipe off surface coating with cotton dampened with acetone, then use HF:H 2 O=1:3 solution to remove the still adhered silicone layer.

Embodiment 3

[0041] Similar to Example 2, the difference is that 0.4 g of zinc powder is ground and then mixed into 0.8 g of organic silica gel. Make the zinc-containing organic silica gel evenly distributed on the gallium arsenide sample with a thickness of 0.6mm, and coat the organic silica gel on the sample after uniform glue, the thickness of the organic silica gel layer is 1mm, and then put it in a drying oven for drying Until the glue solidifies naturally, the drying temperature is 100°C.

[0042] Diffusion is carried out in a rapid thermal annealing furnace with zinc-containing organic silica gel as the diffusion impurity source, nitrogen is used as the protective gas, and the gas flow rate is 4ml / m 3 , for diffusion, the diffusion temperature is 600-620°C, and the diffusion time is 25-35min;

[0043] Wipe off surface coating with cotton dampened with acetone, then use HF:H 2 O=1:5 solution to remove the still adhered silicone layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com