Test method of alloy gold containing gold and silver and platinum group metal

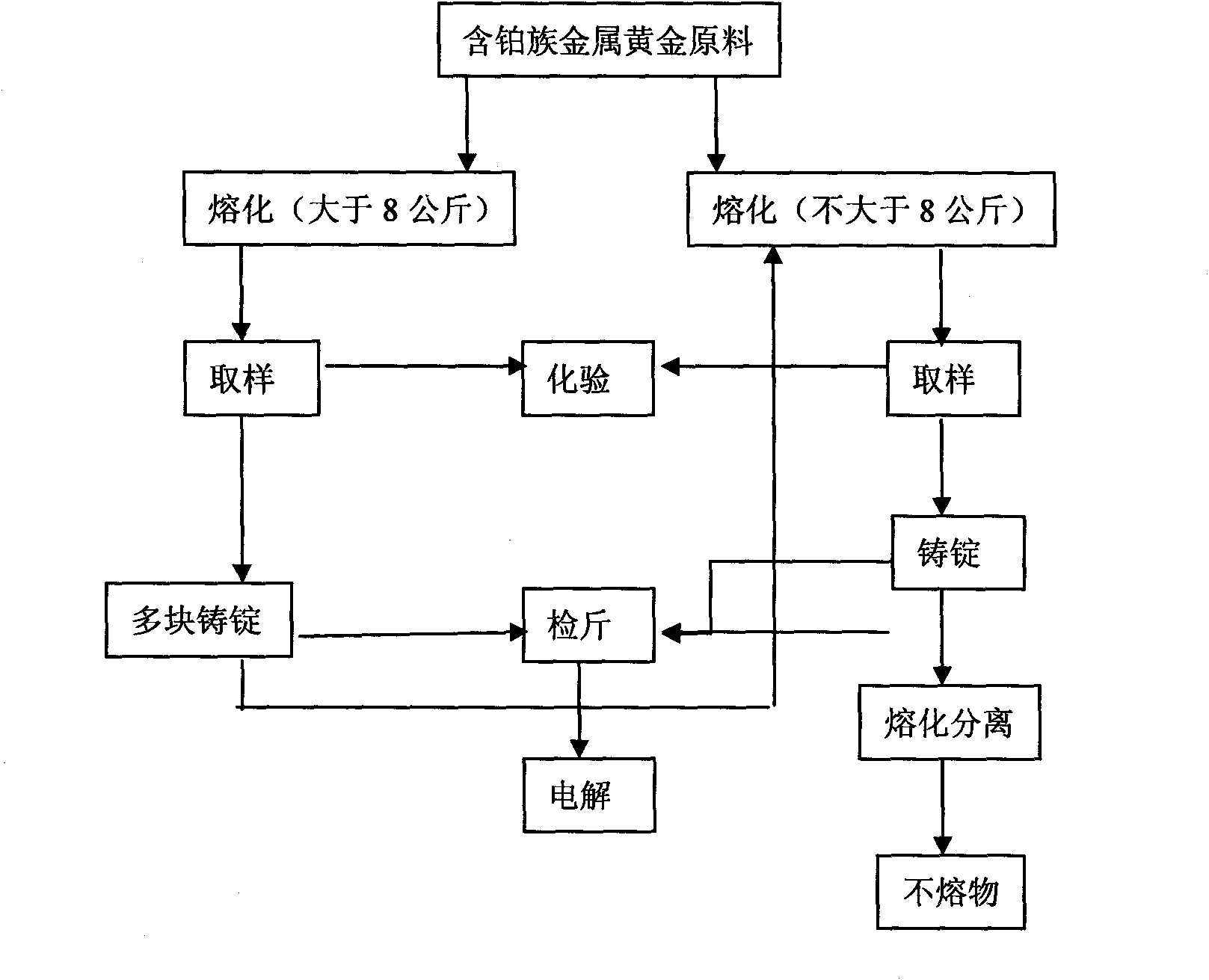

A platinum group metal and alloy gold technology, applied in the field of smelting, can solve the problems of production and operation difficulties of gold refining enterprises, the inability to accurately measure the gold content, and the difficulty of separation of fused gold, so as to shorten the production cycle, solve the backlog of precious metals, The effect of shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An acceptance method for alloy gold containing gold, silver and platinum group metals. The weight of the gold material is 6.5Kg, and the acceptance is accepted by melting with an oxyacetylene cutting torch:

[0025] (1) Carefully observe whether there are obvious lumps on the surface of the material and whether the surface color is consistent. If any abnormality is found, it should be determined as a key monitoring object. When melting and accepting, it must be highly valued and carefully operated;

[0026] (2) Each melting and feeding should not exceed 3.5Kg, and more than 3.5Kg can be checked and accepted in batches to ensure that the principle of "slow and trickle flow" is adhered to when casting after melting;

[0027] (3) The melting temperature of the material is maintained at 1250°C-1300°C for 10 minutes. After the gold raw material containing platinum group metals is melted, carefully observe the liquid material. If there is a block of refractory material or the ...

Embodiment 2

[0032] The weight of the gold material is 16Kg. The graphite crucible (No. 30) is melted in an intermediate frequency furnace. The gold material is fully melted at 1250°C-1300°C and then left for 10 seconds. Sampling is carried out before casting. The flow is poured into the mold and cooled to form an ingot, and at the same time, the material in the crucible is heated with an oxygen acetylene cutting torch. After each ingot is cast, the crucible is gently shaken and the next one is cast. Pour into the pre-prepared quartz crucible when the remaining material is 2Kg, continue heating and observing with an oxygen acetylene cutting torch, and the following steps are the same as those in Example 1.

Embodiment 3

[0034] Gold material weighs 60Kg, adopts No. 30 graphite crucibles; Except that in the first step, it will be melted in stages (can be according to each 30Kg), other is the same as embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com