Method for processing solvent and byproducts in aromatic carboxylic acid production

A technology for aromatic carboxylic acids and by-products, which is applied in the field of comprehensive treatment of solvents and by-products in the production of aromatic carboxylic acids, which can solve problems such as high heat of vaporization, high energy consumption of devices, and large amount of steam, so as to reduce consumption and reduce acetic acid Unit consumption, the effect of increasing economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

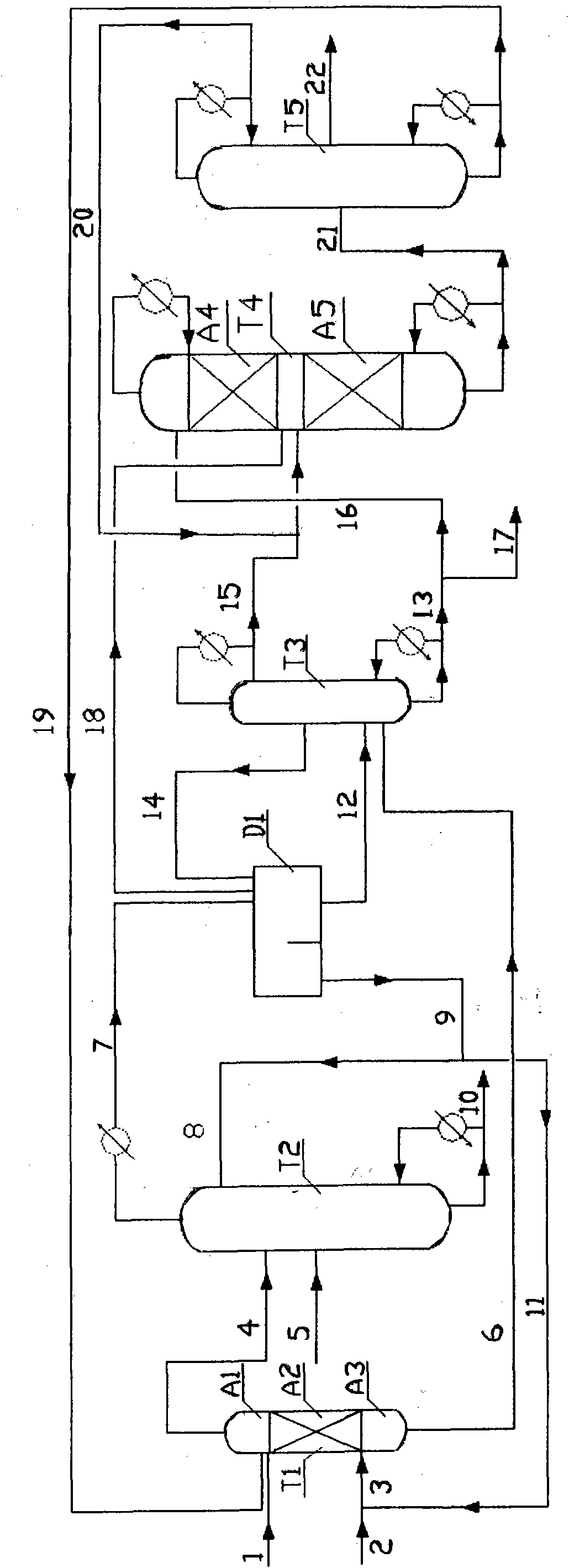

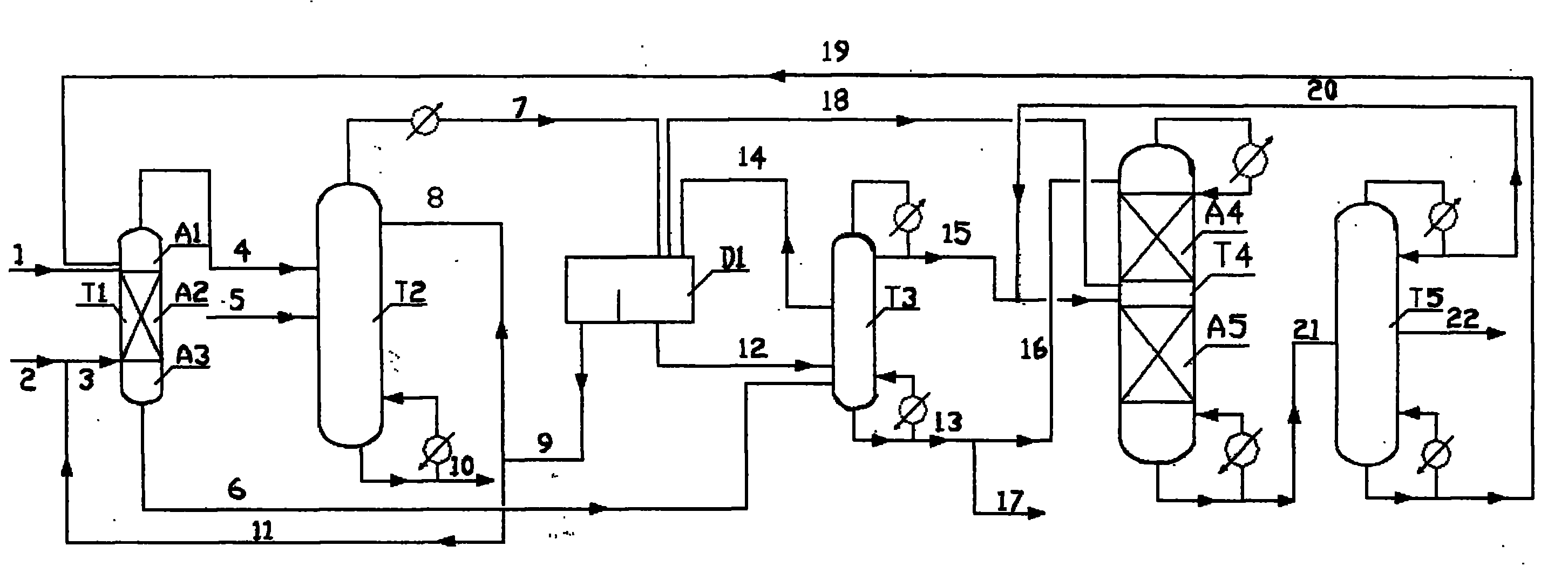

Image

Examples

Embodiment 1

[0026] A. 35000kg / h of acetic acid mixed solution from the water extraction process (containing 14070kg / h of acetic acid, 20265kg / h of water, 665kg / h of methyl acetate), and 3435kg / h of dilute solution from the hydrolysis device of methyl acetate (containing 1305kg of acetic acid / h, water 2130kg / h) enters from the top of the packing section of the extraction tower, 54300kg / h in the organic phase after decanter stratification (containing isobutyl acetate 50499kg / h, water 1955kg / h, methyl acetate 1846kg / h h) It enters from the bottom of the packing section of the extraction tower, contacts in countercurrent in the extraction tower, and obtains a raffinate phase of 11563kg / h (containing acetic acid 2kg / h, isobutyl acetate 48kg / h, water 11466kg / h, methyl acetate ester 47kg / h), the tower top obtains extract phase 81172kg / h (containing acetic acid 15373kg / h, isobutyl acetate 50451kg / h, water 12884kg / h, methyl acetate 2464kg / h);

[0027] B. Extraction tower overhead extraction phase...

Embodiment 2

[0033] A. Acetic acid mixed solution 35689kg / h (containing acetic acid 13148kg / h, water 21947kg / h, methyl acetate 594kg / h) from the water extraction process, and dilute solution 5231kg / h (containing acetic acid 942kg / h, water 4289kg / h) enters from the top of the packing section of the extraction tower, 109720kg / h in the organic phase after decanter stratification (containing propyl acetate 87776kg / h, water 17555kg / h, methyl acetate 4389kg / h ) enters from the bottom of the packing section of the extraction tower, contacts in countercurrent in the extraction tower, and obtains the raffinate phase 25252kg / h (containing acetic acid 2kg / h, propyl acetate 218kg / h, water 24886kg / h, methyl acetate 146kg / h), tower top obtains extraction phase 125388kg / h (containing acetic acid 14088kg / h, propyl acetate 87558kg / h, water 18905kg / h, methyl acetate 4837kg / h);

[0034] B. the extraction tower overhead extraction phase 125388kg / h in the step A (containing acetic acid 14088kg / h, propyl acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com