Copper polysilicate, preparation method thereof and application thereof in water treatment

A technology of copper-silicon and copper salts, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, copper compounds, etc., can solve the problems of unseen preparation methods of poly-copper-silicon salt catalysts, high toxicity of by-products, etc., and achieve improved oxidation The effect of high performance and utilization rate, strong activity and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

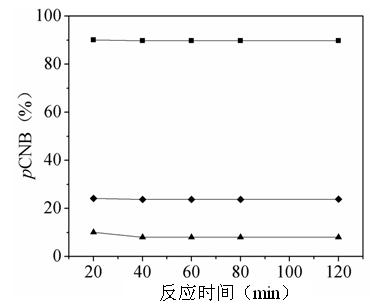

Image

Examples

specific Embodiment approach 1

[0008] Embodiment 1: In this embodiment, the polycopper silicon salt is made by adding the alkali metal silicate aqueous solution dropwise into the soluble copper salt aqueous solution, and then sieving through static sedimentation, activation, filtration, washing, drying, and grinding. wherein, the alkali metal silicate aqueous solution is added dropwise to the soluble copper salt aqueous solution until the pH value is 8-9.

[0009] The polycopper silicon salt described in this embodiment is solid, amorphous, blue-green in color, with a particle size of 0.1-0.5 mm, and can completely settle after standing in water for 2 minutes, with a specific surface area of 377.1597 m? / g.

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment is different from Embodiment 1 in that: the soluble copper salt in the soluble copper salt aqueous solution is copper nitrate, copper sulfate or copper chloride. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the alkali metal silicate in the alkali metal silicate aqueous solution is sodium silicate, potassium silicate or sodium metasilicate. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com