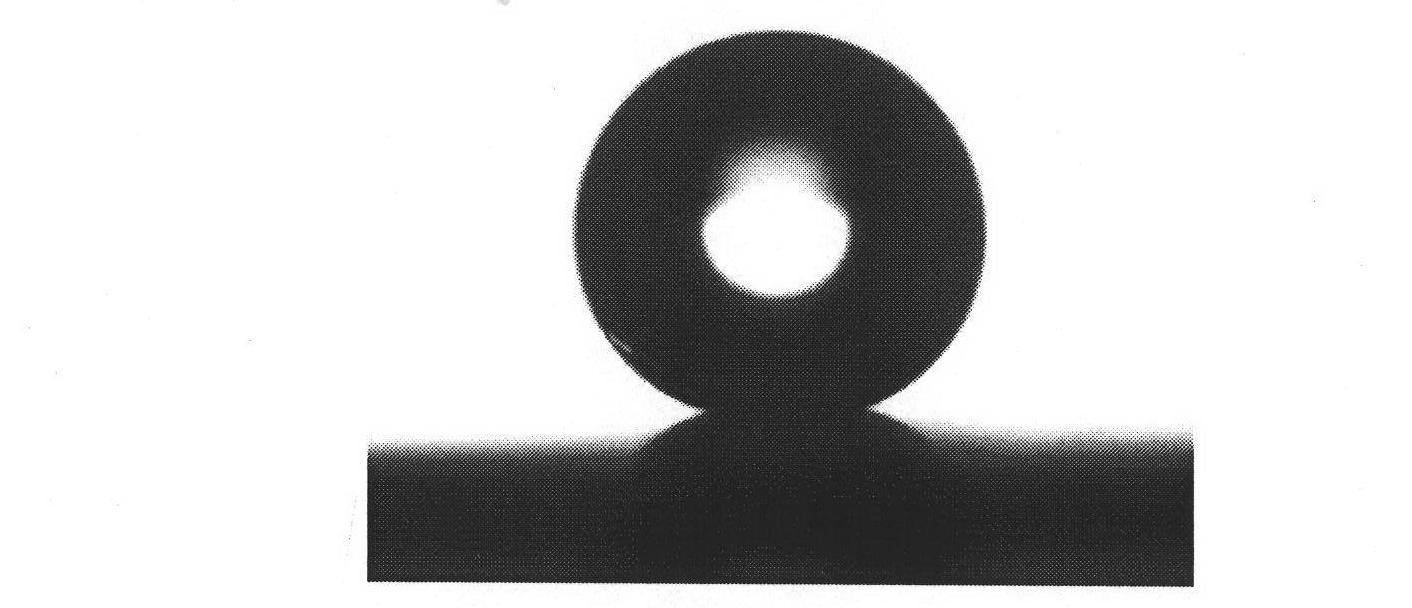

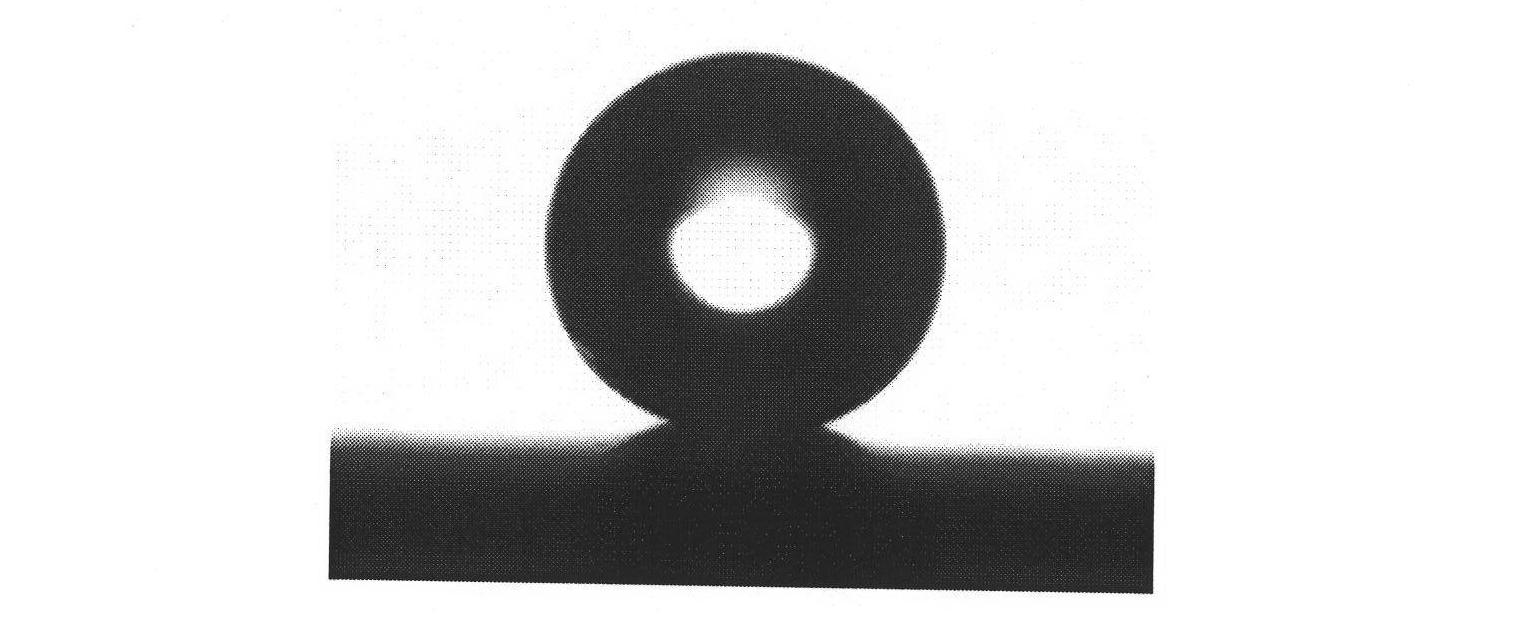

Preparation method of self-repairing super hydrophobic coating

A super-hydrophobic coating, self-healing technology, applied in the direction of cleaning methods, coatings, chemical instruments and methods using liquids, etc., to achieve the effects of easy availability of raw materials, simple process, and good self-cleaning properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Treatment of the substrate:

[0029] The silicon wafer was ultrasonically treated with ethanol and distilled water for 10 minutes respectively to remove various impurities (grease and dirt) attached to the surface of the substrate, and then dried with nitrogen gas for use.

[0030] (2) Preparation of solution:

[0031] Pour 50mL, 0.2mg / mL deionized aqueous solution of sulfonated polyaniline into 50mL, 0.4mg / mL deionized aqueous solution of polydimethyldiallylamine hydrochloride to prepare a complex solution for use; then Dissolve 0.4g of polyacrylic acid in 100mL of deionized water, and dissolve evenly before use.

[0032] (3) Preparation of micro-nano composite surface:

[0033] Soak the silicon chip processed in step (1) in the deionized aqueous solution of polyacrylic acid prepared in step (2) for 10 minutes, take out and rinse with deionized water; then prepare the composite solution in step (2) Soak in water for 10 minutes, take it out and rinse it with deio...

Embodiment 2

[0040] (1) Treatment of the substrate:

[0041] The aluminum sheet was ultrasonically treated with ethanol and distilled water for 10 minutes respectively to remove various impurities attached to the surface of the substrate, and then dried with nitrogen gas for use.

[0042] (2) Preparation of solution:

[0043] Pour 100mL, 0.4mg / mL deionized aqueous solution of sulfonated polyaniline into 50mL, 1mg / mL deionized aqueous solution of polydimethyldiallylamine hydrochloride to prepare a complex solution, ready for use; Then dissolve 0.4g of polymethacrylic acid in 100mL of deionized water, dissolve evenly and set aside.

[0044] (3) Preparation of micro-nano composite surface:

[0045] Soak the aluminum sheet processed in the step (1) in the polymethacrylic acid solution prepared in the step (2) for 5 minutes, take out and wash it; then soak it in the composite solution prepared in the step (2) for 5 minutes, Take it out and wash it with water; repeat the above process 15 time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com