Multi-color light adjustment mask, its manufacture method and a pattern transfer-printing method

A manufacturing method and photomask technology, which is applied in the field of multi-color photomasks, can solve problems such as difficulty in producing grayscale masks, and achieve the effects of suppressing poor operation and suppressing the decrease in transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, several embodiments of the present invention will be described with reference to the drawings.

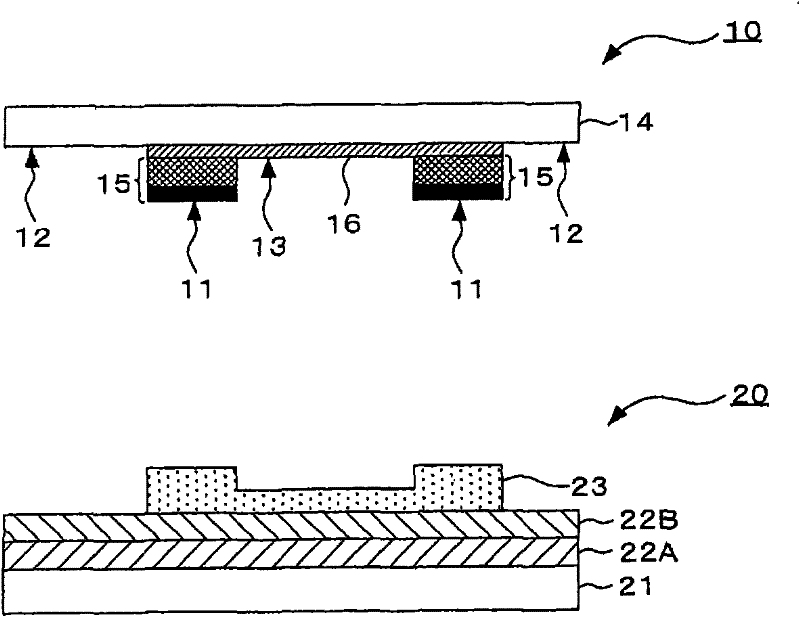

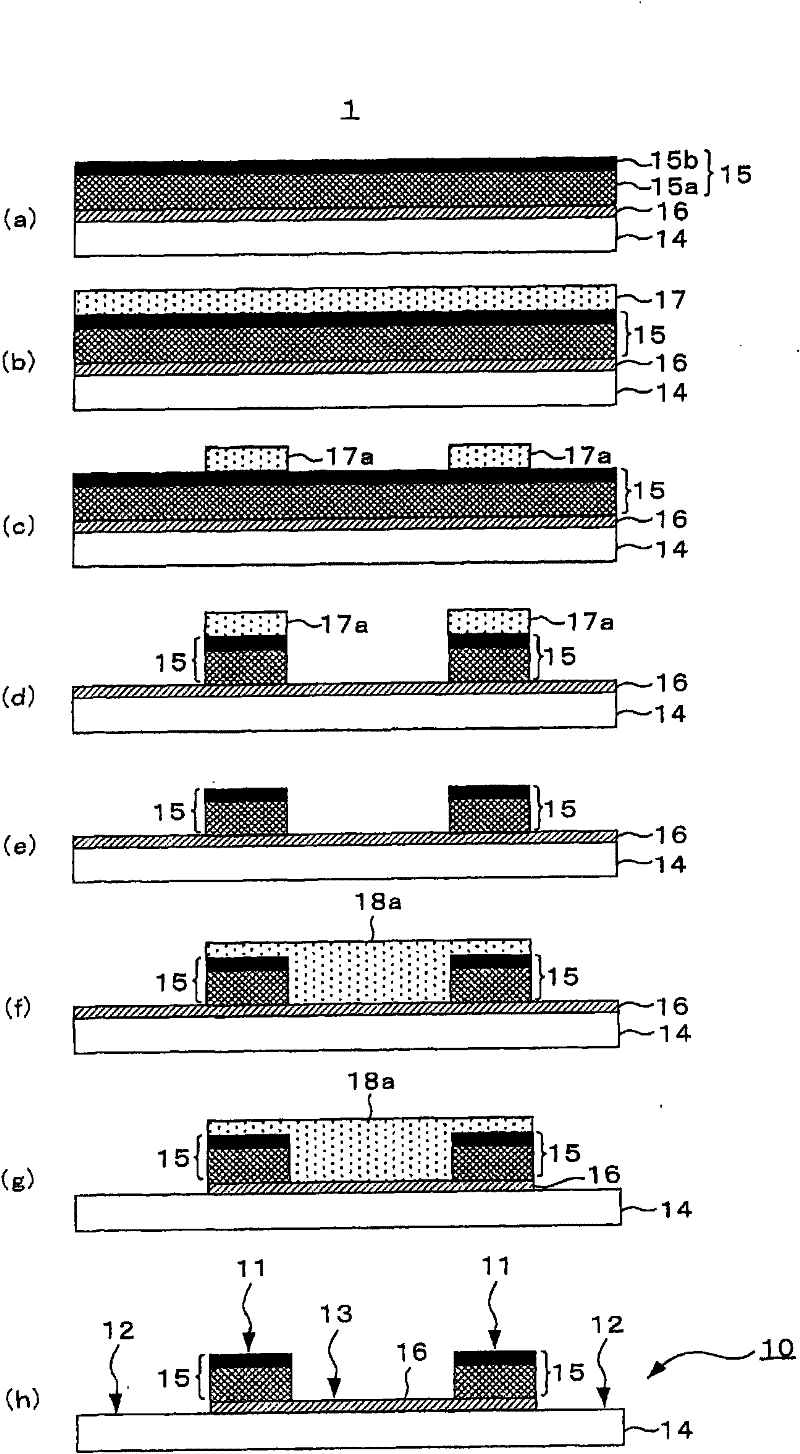

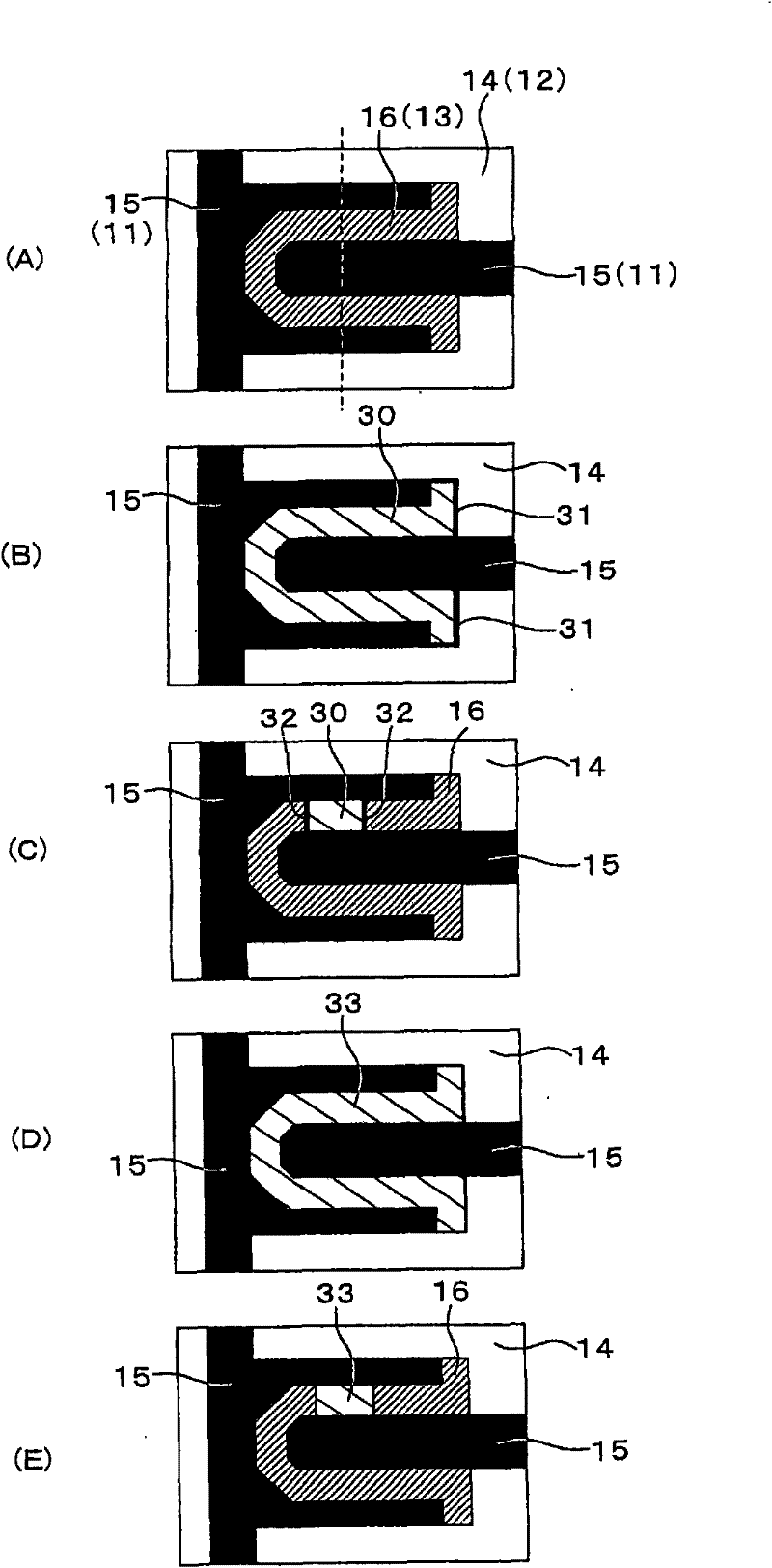

[0055] figure 1 It is a cross-sectional view for explaining a pattern transfer method using a multi-color photomask. figure 1 The shown multi-color photomask 10 is used, for example, to manufacture electronic devices such as thin-film transistors (TFTs) of liquid crystal display devices (LCDs). figure 1 Two or more resist patterns 23 having different film thicknesses stepwise or continuously are formed on the transfer target body 20 shown. also, figure 1 Reference numerals 22A and 22B denote films laminated on the substrate 21 in the body to be transferred 20 .

[0056] An example of a three-tone mask in which the above-mentioned multi-color light mask 10 has a semi-transparent portion in addition to the light-shielding portion and the light-transmitting portion is shown. Specifically, the multi-color light mask 10 is configured to have: part 11, which block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com