Engine plateau environment laboratory

A plateau environment and engine technology, applied in engine testing, machine/structural component testing, measuring devices, etc., can solve the problem of inability to simulate and concentrate in one, the plateau environment is not realistic enough, and the accuracy and efficiency of the engine high-altitude environment test are affected. problems to ensure accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

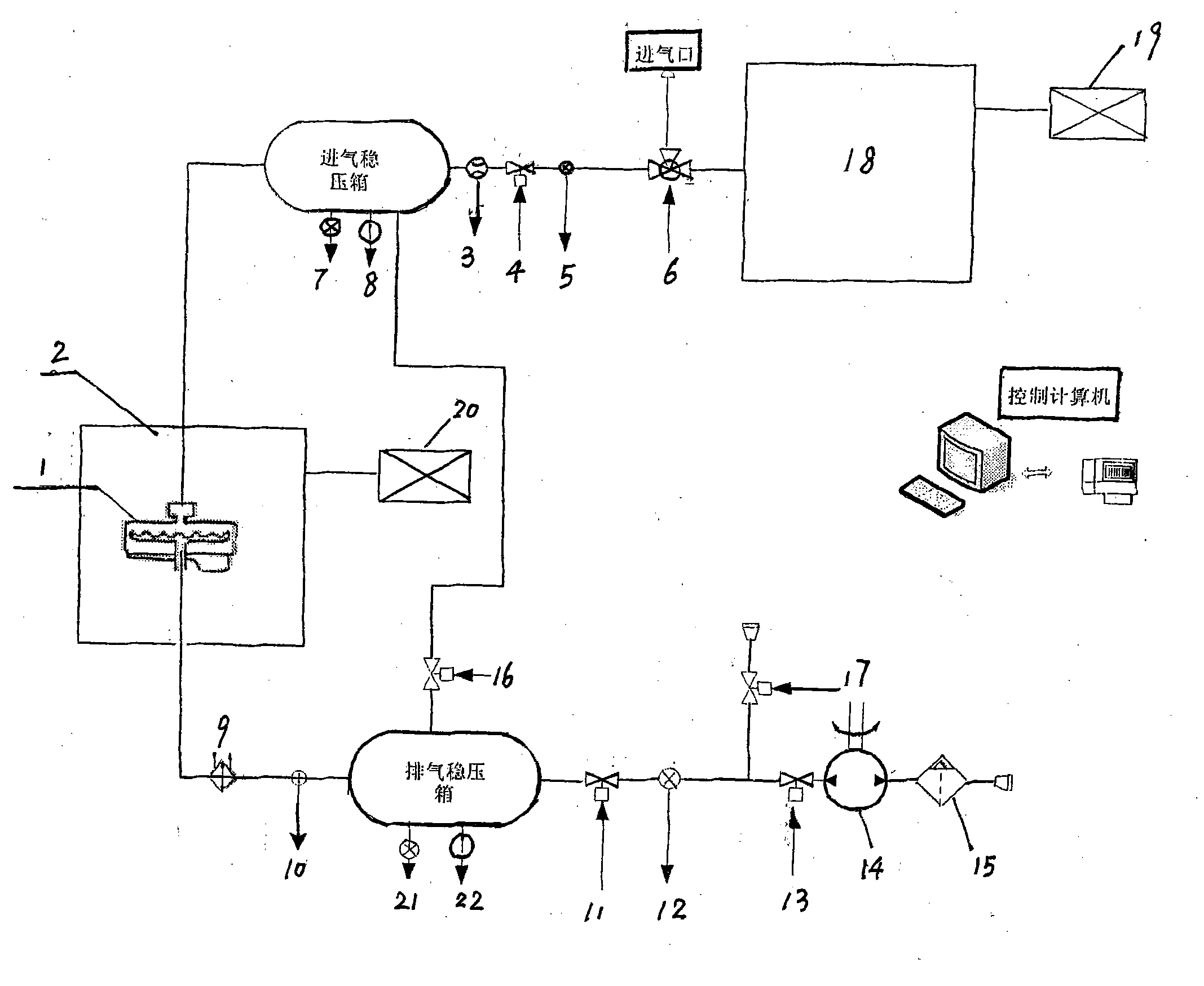

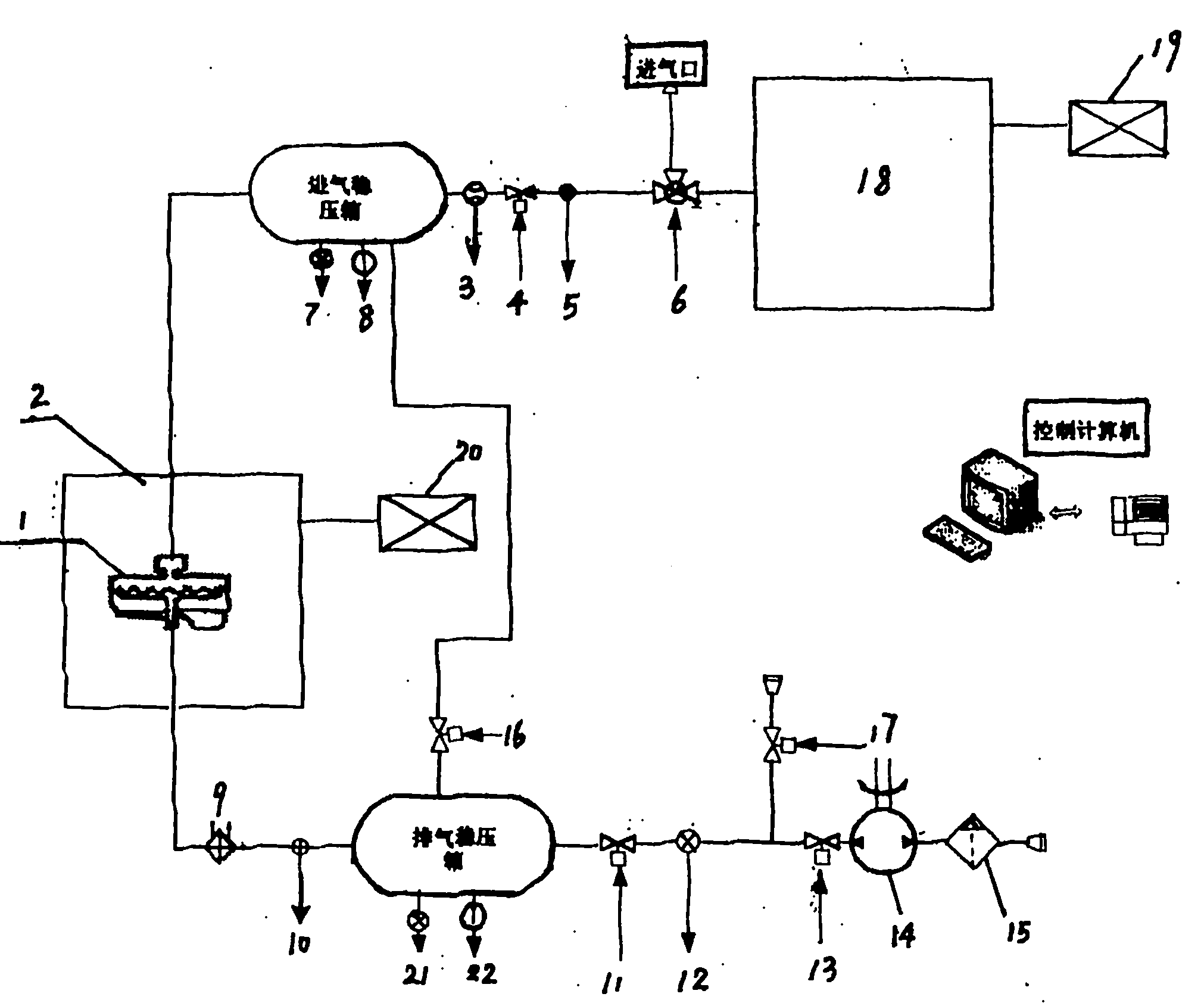

[0016] As shown in the figure: an engine plateau environment laboratory, which consists of an intake pressure simulation system, an exhaust pressure simulation system, a high and low temperature control cabin 2 for placing the engine 1 and a control system. The intake air pressure simulation system is composed of an intake air regulator box, a low temperature box 18 and a refrigeration unit 19 connected in sequence. An air flow meter 3, an air intake electric regulating valve 4, a pressure sensor 5 and a three-way valve 6 are installed on the pipeline connecting the box and the low temperature box, and a pressure sensor 7 and a temperature sensor 8 are installed on the air intake stabilizing box. The exhaust pressure simulation system consists of an exhaust heat exchanger, an exhaust pressure regulator box, an exhaust electric regulating valve, a vacuum pump and a gas-water separator. The inlet of the exhaust heat exchanger 9 communicates with the air outlet of the engine plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com