Preparation method of aluminum-cladding boron composite powder

A composite powder, aluminum coating technology, used in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve problems such as difficulty, uneven coating structure, difficult melting and gasification, etc. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

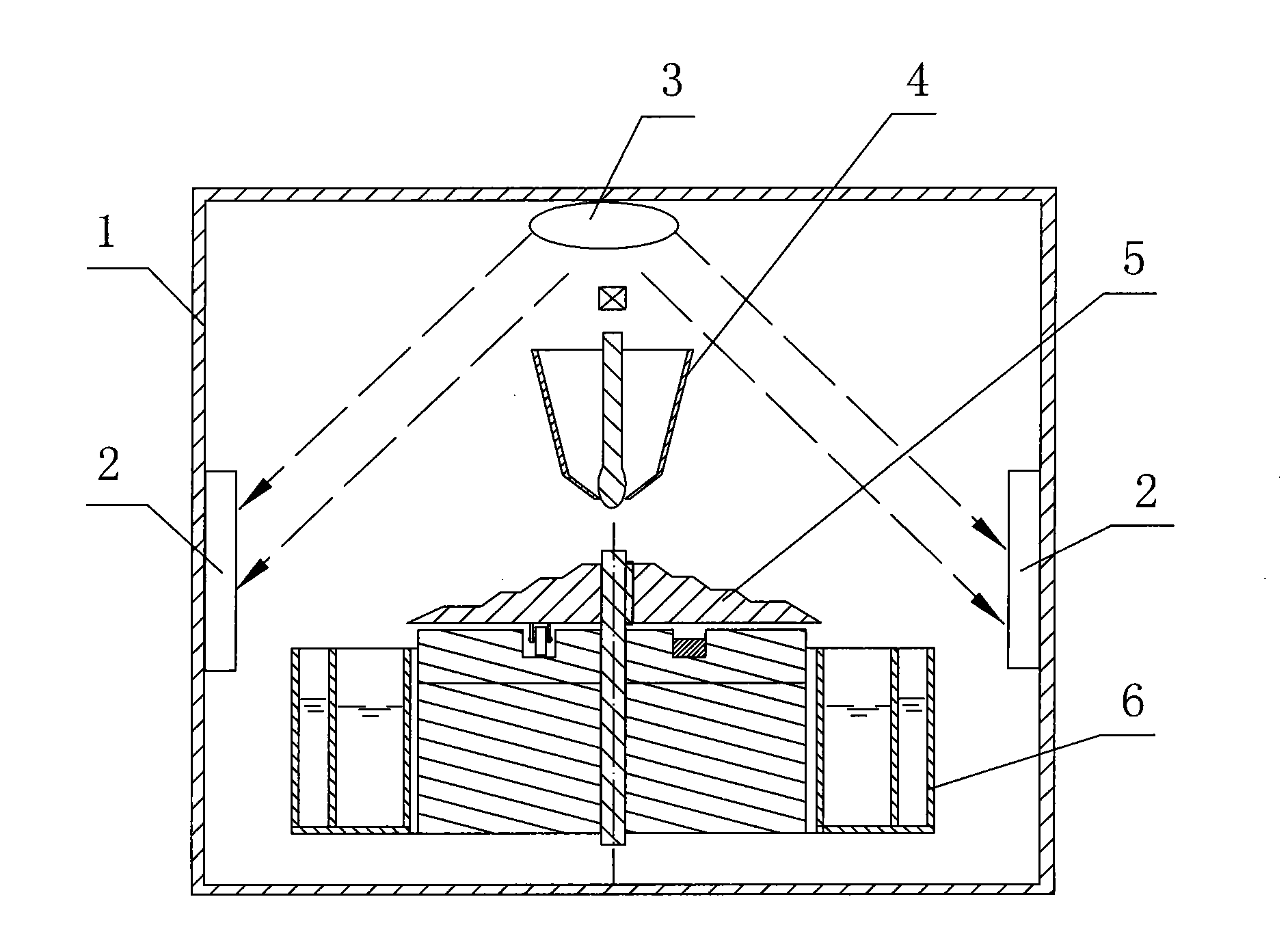

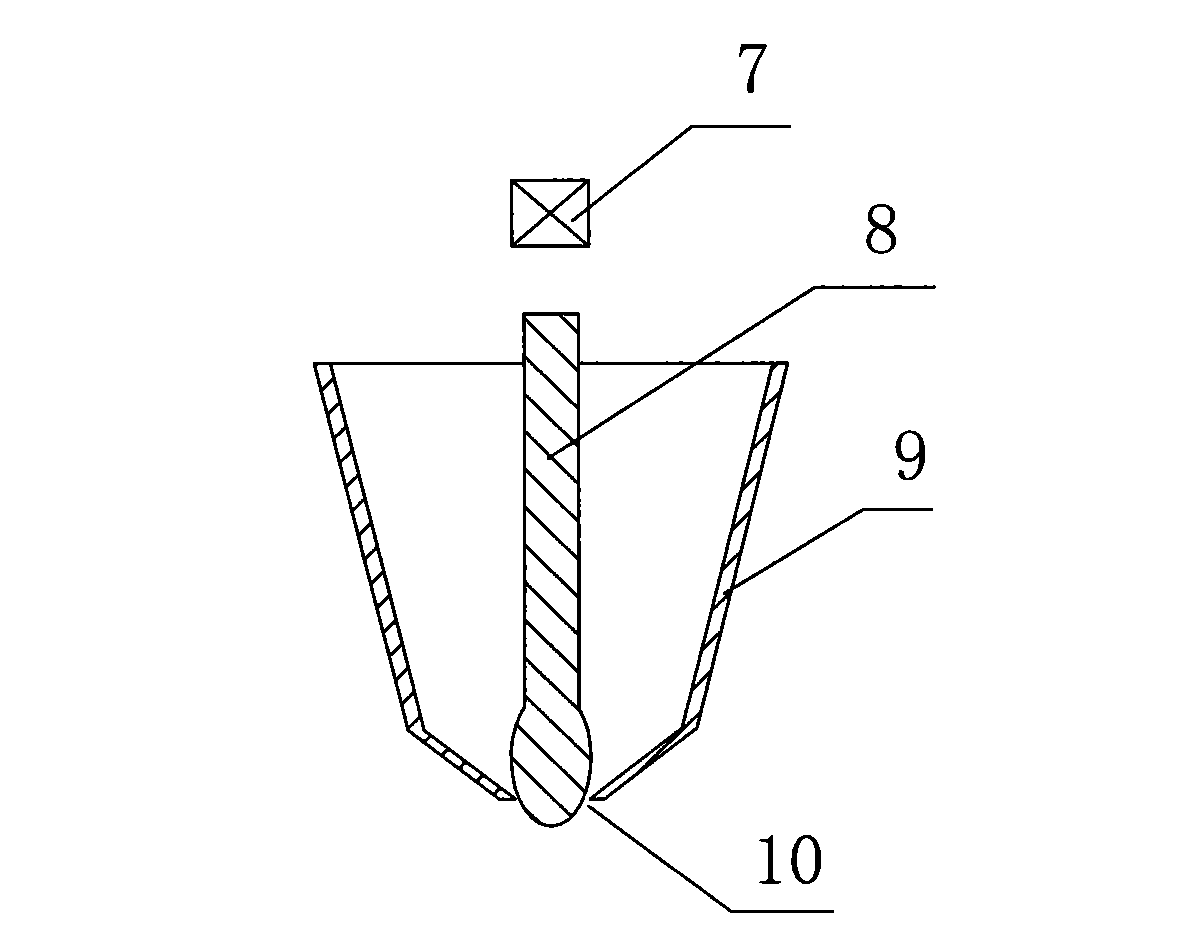

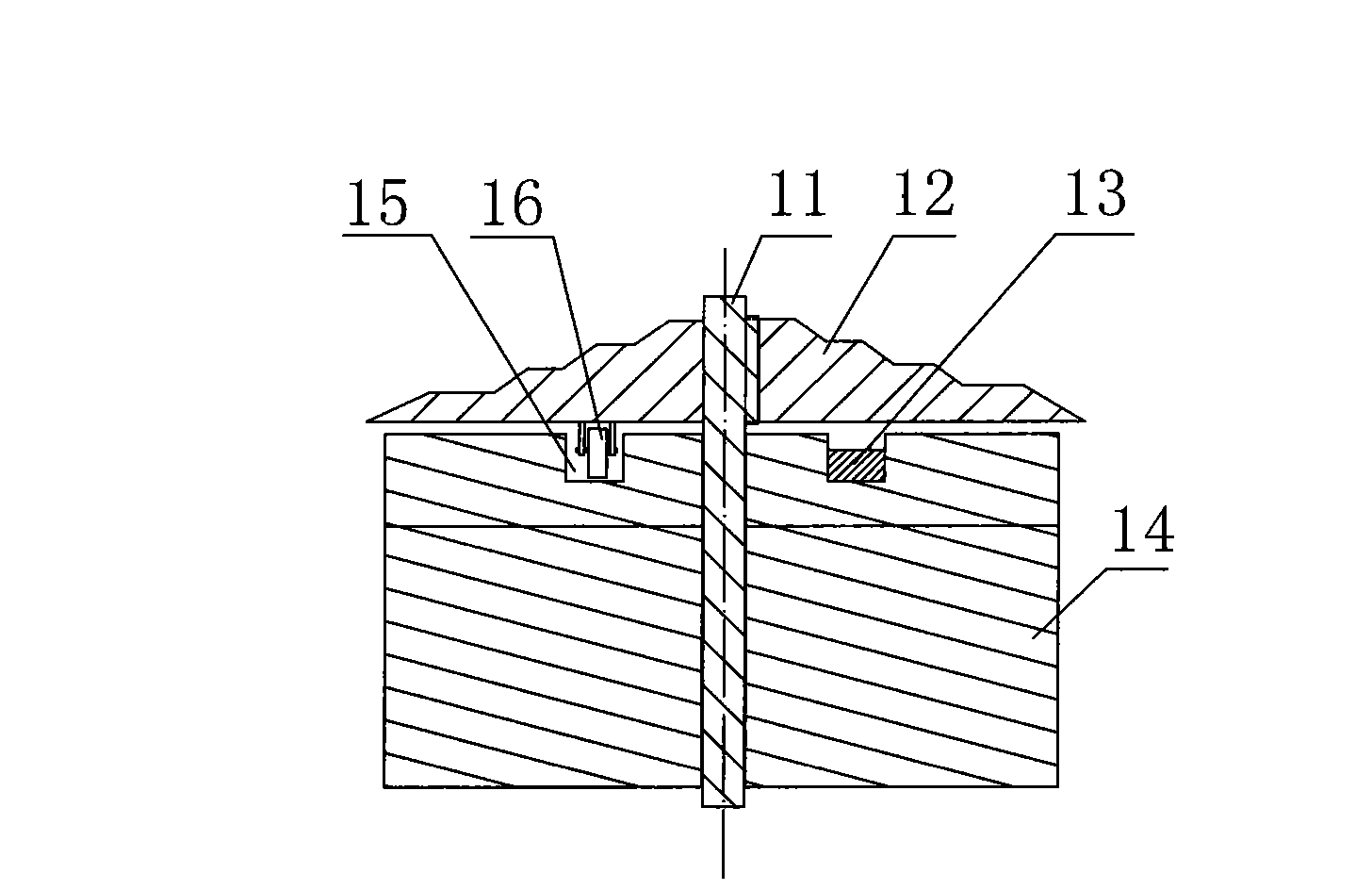

[0036] Such as Figure 7 Shown, a kind of preparation method of aluminum-coated boron composite powder, it comprises the steps:

[0037] Take 3 kg of granulated boron powder with a particle size of 50-80 μm, and then put it into the feeding hopper of the multi-arc ion coating machine. Set the feeding speed to 15g / min, the total coating time to 200 minutes, set the rotating speed of the loading platform to 3 rpm, the vibration frequency to 18 times / min, and the coating time to 5-8 minutes for the powder monomer. The target material in the vacuum furnace body of the multi-arc ion coating machine is an aluminum target. Vacuum to 2.0×10 -2 Pa, firstly clean the target (argon to 2Pa, 5min), and then evacuate to 2.0×10 -2 Pa. The vacuum furnace body is heated to a coating temperature of 200°C. Then filled with argon to 2.5×10 -1 Pa, the current of the argon emission source (that is, the arc source) is 60A (the voltage is passively adjusted with the current and air pressure). ...

Embodiment 2

[0039] A method for preparing an aluminum-coated boron composite powder, comprising the steps of:

[0040] Take 6 kg of granulated boron powder with a particle size of 30-50 μm, and then put it into the feeding hopper of the multi-arc ion coating machine. Set the feeding speed to 15g / min, the total coating time to 400 minutes, set the rotating speed of the loading platform to 4 rpm, the vibration frequency to 24 times / min, and the coating time to 3 to 4 minutes for the powder monomer. The target material in the vacuum furnace body of the multi-arc ion coating machine is an aluminum target. Vacuum to 2.0×10 -2 Pa. Firstly, the target is cleaned (pass argon to 2Pa, 5min), and then vacuumize to 2.0×10 -2 Pa. The vacuum furnace body is heated to a coating temperature of 180°C. Then filled with argon to 2.5×10 -1 Pa, the current of the argon emission source (that is, the arc source) is 55A (the voltage is passively adjusted with the current and air pressure). The granulated ...

Embodiment 3

[0042] A method for preparing an aluminum-coated boron composite powder, comprising the steps of:

[0043] Take 10 kg of granulated boron powder with a particle size of 80-100 μm, and then put it into the feeding hopper of the multi-arc ion coating machine. Set the feeding speed to 20g / min, the total coating time to 500 minutes, set the rotating speed of the carrying table to 2 rpm, the vibration frequency to 6 times / min, and the coating time to 8-10 minutes for the powder monomer. The target material in the vacuum furnace body of the multi-arc ion coating machine is an aluminum target. Vacuum to 2.0×10 -2 Pa, firstly clean the target (argon to 2Pa, 5min), and then evacuate to 2.0×10 -2 Pa. The vacuum furnace body is heated to a coating temperature of 170°C. Then filled with argon to 2.5×10 -1 Pa, the current of the argon emission source (that is, the arc source) is 70A (the voltage is passively adjusted with the current and air pressure). The granulated boron powder fal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com