Method for increasing leaching rate of navajoite under navajoite kiln roasting condition

A vanadium ore roasting technology, applied in the field of improving the vanadium ore leaching rate, can solve the problems of low leaching rate, unreasonable proportion, uneven particle size of green pellets, etc., and achieve the effect of improving the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

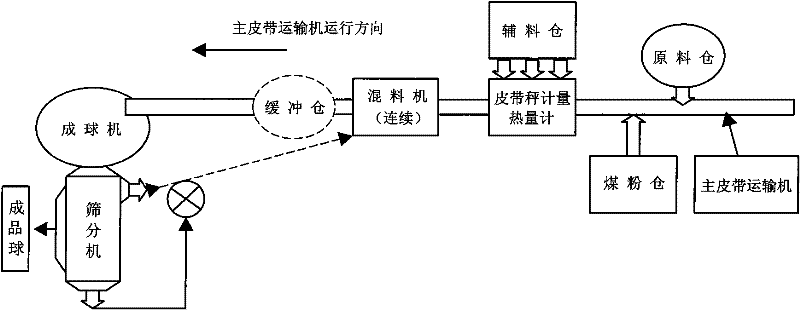

[0018] As shown in the figure, with NaCl and Na 2 CO 3 Put it into the auxiliary material bin as auxiliary materials, and put vanadium ore powder as raw material into the raw material bin, wherein the vanadium ore powder with a particle size of 2 CO 3 Accurately measure 10 parts of NaCl, Na 2 CO 3 3 parts are sent to the main belt conveyor; the raw materials and auxiliary materials enter the mixer set at the front end of the main belt conveyor through the main belt conveyor for mixing, and after mixing, they are sent to the buffer bin, and then sent to the ball forming machine through the buffer bin, and after being balled Machine-made raw balls, each of the described mixing machine and the ball forming machine is one. After being sieved by the sieving machine, the green balls with a diameter of 8-13mm are transported to the flat kiln, and the green balls with a diameter of 13mm are returned to the mixer; the green balls entering the flat kiln are roasted and roasted. The ...

Embodiment 2

[0020] As shown in the figure, with NaCl and Na 2 CO 3 Put the auxiliary material into the auxiliary material warehouse, and put the vanadium ore powder as the raw material into the raw material warehouse, wherein the vanadium ore powder with a particle size of 2 CO 3 Accurately measure 8 parts of NaCl, Na 2 CO 3 4 parts are sent to the main belt conveyor; the raw and auxiliary materials enter the mixer set at the front end of the main belt conveyor through the main belt conveyor for mixing, and after mixing, they are sent to the buffer bin, and then sent to the ball forming machine through the buffer bin, and after being balled Machine-made raw balls, each of the described mixing machine and the ball forming machine is one. After being sieved by the sieving machine, the green balls with a diameter of 8-13mm are transported to the flat kiln, and the green balls with a diameter of 13mm are returned to the mixer; the green balls entering the flat kiln are roasted and roasted...

Embodiment 3

[0022] As shown in the figure, with NaCl and Na 2 CO 3 Put it into the auxiliary material warehouse as an auxiliary material, and put it into the raw material warehouse with vanadium ore powder as raw material, wherein the vanadium ore powder with a particle size of 2 CO 3 Accurately measure 8-10 parts of NaCl, Na 2 CO 3 3-4 parts are sent to the main belt conveyor; the raw and auxiliary materials enter the mixer set at the front end of the main belt conveyor through the main belt conveyor for mixing. The ball forming machine produces raw balls, and each of the mixer and the ball forming machine is one. After being sieved by the sieving machine, the green balls with a diameter of 8-13mm are transported to the flat kiln, and the green balls with a diameter of 13mm are returned to the mixer; the green balls entering the flat kiln are roasted and roasted. The temperature is 700°C, and the temperature is kept for 2.5 hours to obtain the finished ball, and the leaching rate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com