Icing sugar spray drying system with high DE value

A technology of drying system and sugar powder, which is applied in sugar drying, spray evaporation, sucrose production, etc. It can solve the problems of small air volume, sugar powder is easy to stick to the wall, and sugar powder absorbs moisture and sticks to the wall, so as to prevent moisture absorption and stick to the wall, and eliminate pumps. Absorption phenomenon, reducing the effect of dry powder returning to the top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

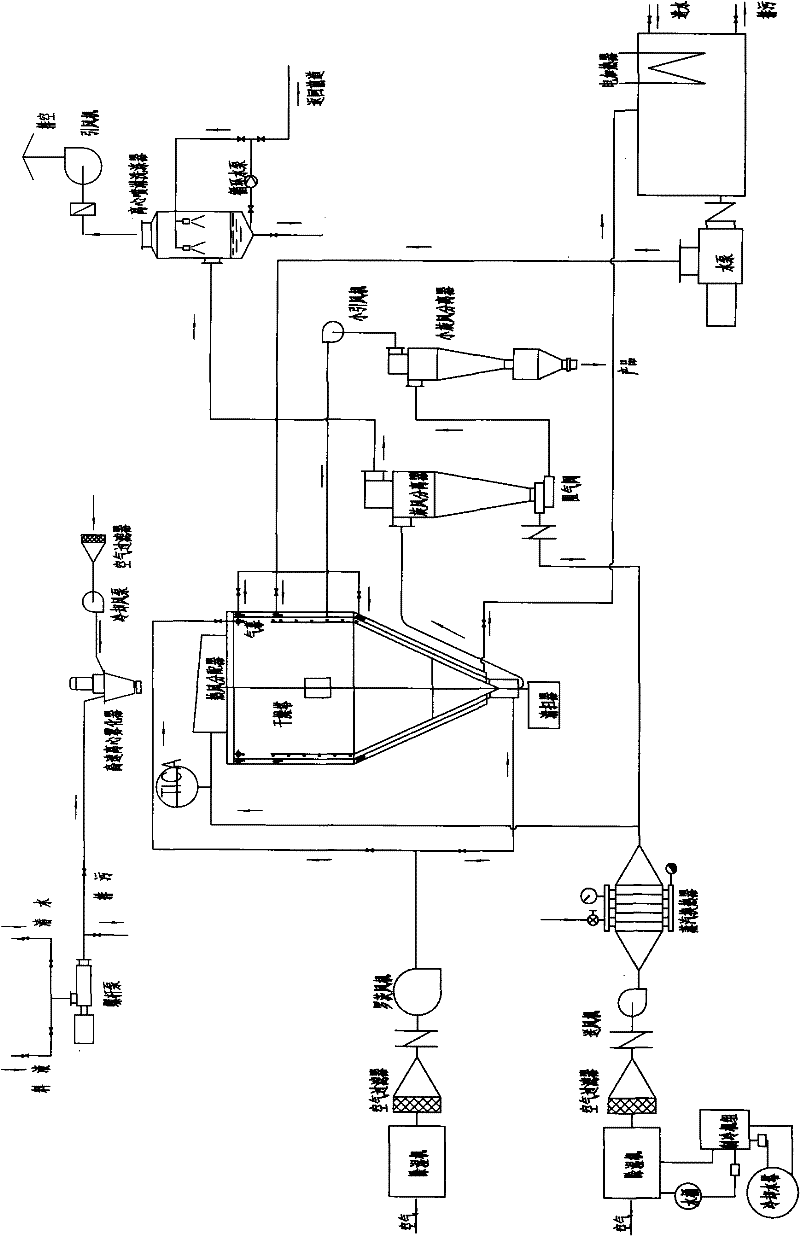

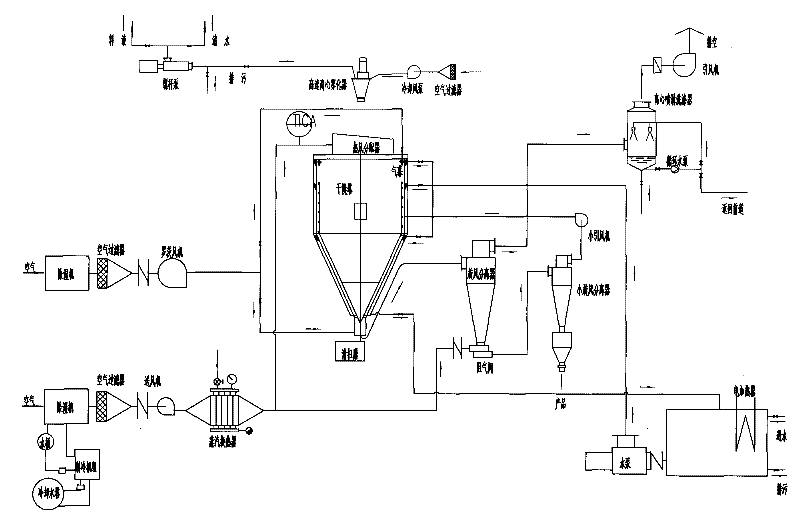

[0025] Such as figure 1 As shown, a high DE value powdered sugar spray drying system is composed of a feeding part, a spraying part, a drying part, and an air supply part; Part of the syrup is delivered to the spraying part, after being atomized by the spraying part, it enters the drying part, and the dry hot air is sent to the drying part by the air supply part, and the powdered sugar after evaporating water in the drying part is separated by a cyclone and finally enters the product package; the feeding part The main body is a feeding pump, the spraying part is a centrifugal atomizer, the feeding pump is connected to the centrifugal atomizer through a pipeline, the main body of the drying part is a drying tower, the wall of the drying tower is a double-layer water jacket structure, and the drying tower wall passes The pipeline is connected with the tower wall temperature control device. The tower wall temperature control device includes a water pump, a heater and a temperatur...

Embodiment 2

[0027]A high DE value powdered sugar spray drying system consists of a feeding part, a spraying part, a drying part, and an air supply part. It is transported to the spraying part, after being atomized by the spraying part, it enters the drying part, and the dry hot air is sent to the drying part by the air supply part, and the powdered sugar after evaporating water in the drying part is separated by a cyclone and finally enters the product package; the main body of the feeding part is a The feeding pump, the spraying part is a centrifugal atomizer, the feeding pump is connected to the centrifugal atomizer through pipelines, and the centrifugal atomizer in the spraying part is also connected to an air filter and a cooling air pump through pipelines. The main body of the drying part is a drying tower. The wall of the drying tower is a double-layer water jacket structure. The wall of the drying tower is connected to the temperature control device of the tower wall through pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com