Method for preparing natural green nano inorganic material-modified organic pigment

A technology of nano inorganic materials and organic pigments, applied in the direction of organic dyes, etc., can solve the problems of increasing production cost, complicated process, prolonging process route, etc., and achieve the effects of improving water dispersibility, increasing specific surface area, and shortening process length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the present invention utilizing natural green nano-inorganic materials to modify organic pigments is characterized in that: the natural green nano-inorganic materials are sepiolite, and the method comprises the following steps:

[0025] (1) Primary treatment of sepiolite: raw sepiolite is dried, pulverized, ball milled, and sieved through a 100-mesh sieve, then soaked in distilled water, washed, removed impurities, filtered and dried, then ball-milled, and then passed through a 400-mesh sieve. sieve;

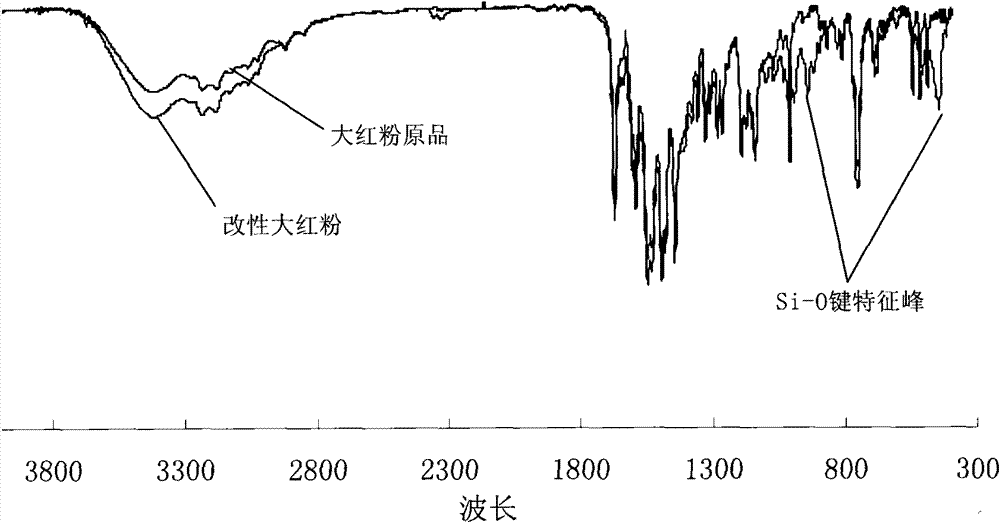

[0026] (2) Sepiolite modification: Stir the treated sepiolite in step (1) evenly with distilled water, and dropwise add 5% to 10% HCl solution five times the quality of the primary treated sepiolite to carry out acidification reaction , and heated at a temperature of 80°C to 90°C, stirred for 10 to 24 hours, and then washed repeatedly with distilled water until there is no chloride ion in the sepiolite, forming a fiber tube with 20 to 400nm in on...

Embodiment 1

[0037] Modified preparation of organic pigment C.I. Pigment Red 21 (12300) red powder:

[0038] The raw sepiolite ore is dried, pulverized, ball milled, passed through a 100-mesh sieve, then soaked in distilled water, washed to remove impurities, filtered and dried, then ball-milled and passed through a 400-mesh sieve. Stir the primary treated sepiolite evenly with distilled water, dropwise add 9% HCl solution 5 times the mass of the primary treated sepiolite, heat at 80°C and stir for 12 hours, then repeatedly wash with distilled water until there is no chlorine in the sepiolite ions, and finally filter and dry the modified sepiolite, and grind it for later use;

[0039] According to the molar ratio of aniline, hydrochloric acid and sodium nitrite of 1:2.7:1.05, the diazotization reaction is carried out at 0-5°C. Add 12mL of water and 3.5mL of 30% hydrochloric acid into the beaker, stir and add 1.2mL of aniline (industrial pure), then add 11mL of water, and add a 30% aqueous...

Embodiment 2

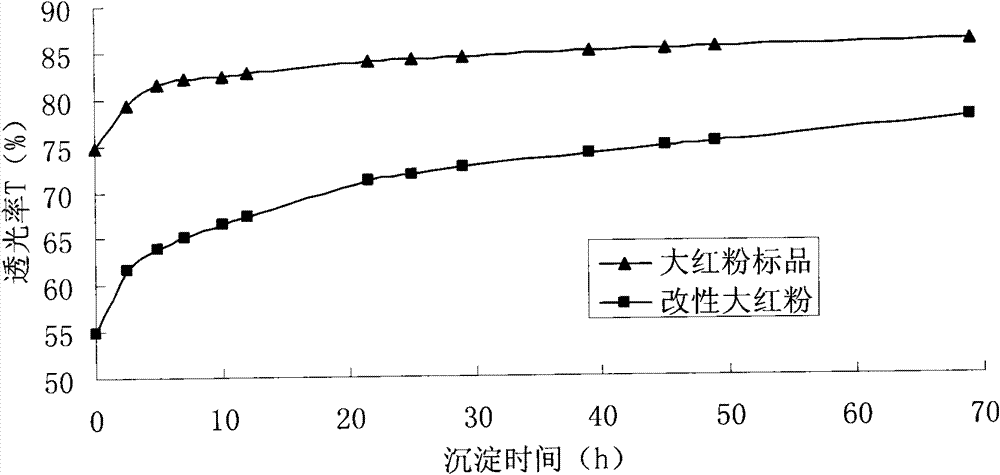

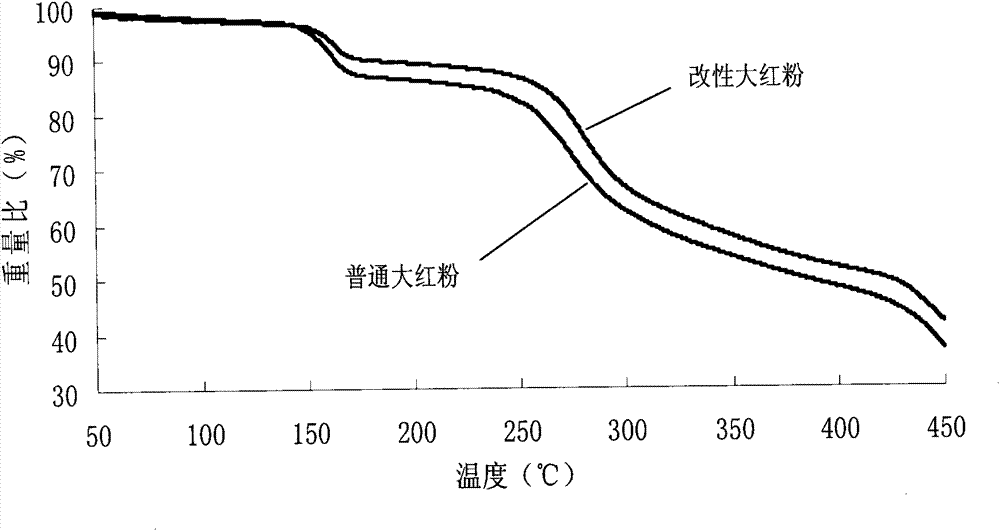

[0043] Preparation of organic pigment C.I. Pigment Red 21 (12310) Jinguanghong by modification:

[0044] The preparation method is the same as that in Example 1, Turkey red oil is not added to the coupling component, and the diazonium salt is added to the coupling component within 10 minutes in the coupling reaction, and the stirring is continued for 3 hours. It is directly filtered, washed with water, and dried without acidification and heat preservation process to obtain The modified Jinguanghong containing 15% sepiolite has a yield close to the theoretical yield, a color strength equivalent to that of the original product, and improved heat resistance and water dispersibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com