Swing mechanism control system for tower crane

A technology of tower crane and slewing mechanism, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of shortening the service life of the equipment, long rolling time, twisting of the tower body, etc., so as to prolong the service life, The effect of reducing the vibration of the tower body and protecting the gearbox

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

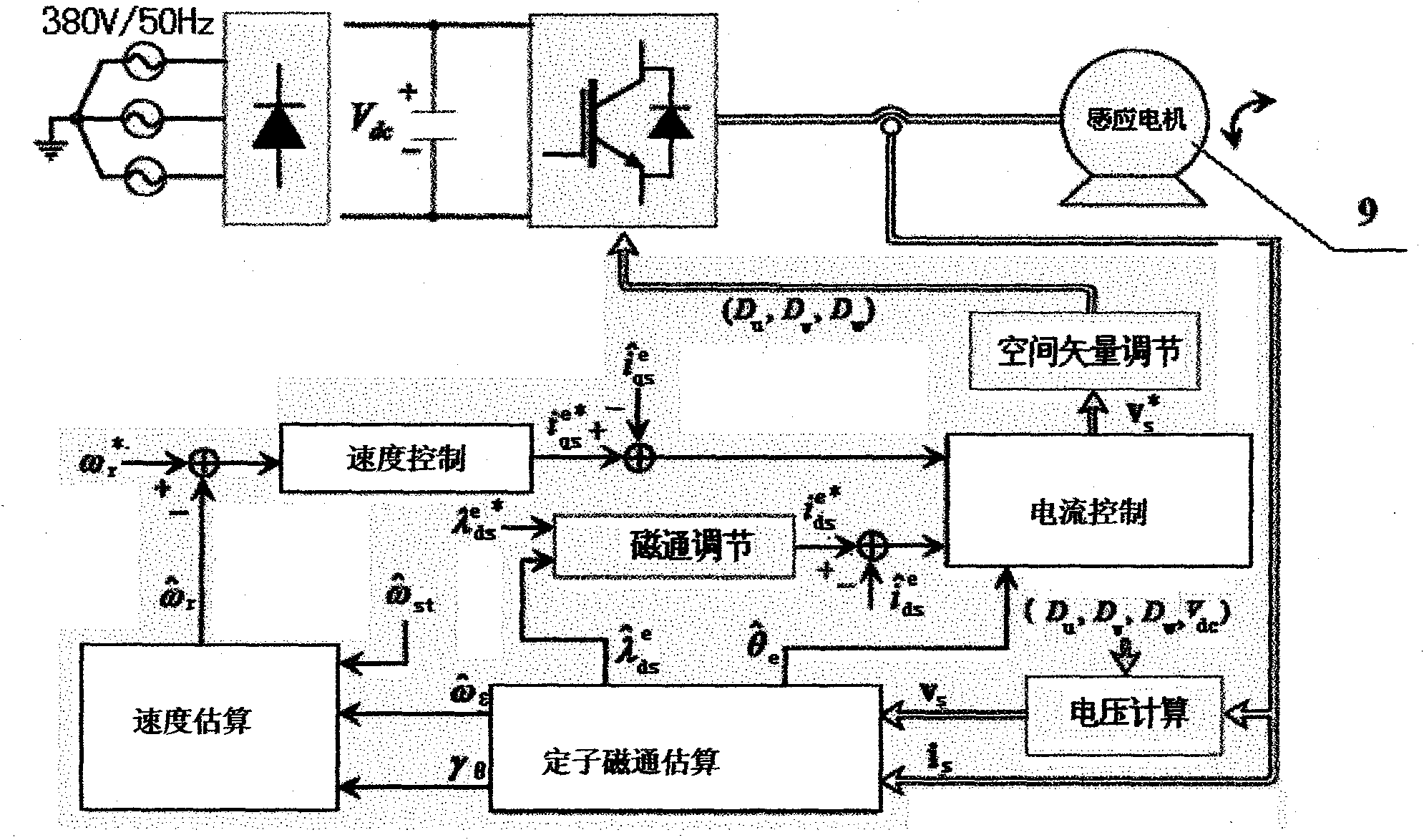

[0030] refer to figure 1 As shown, the slewing mechanism control circuit involved in the present invention includes three parts, a drive system 1, a communication system 2, and a motor system 3. The drive system adopts frequency conversion to do one-to-two vector control mode, and two motors 9 are controlled simultaneously; When the motor 9 was running, it had the same torque and rotating speed. Through the control mode of one dragging multiple motors under vector control (one frequency conversion controls two motors or more motors), it can output precise torque and powerful braking ability to the motors. When the drive system performs parameter self-learning on two coupling motors, the two motors are regarded as one motor for parameter identification.

[0031] The motor system 3 includes two motors 9, two brake controllers 8 and two circuit breakers 7; one end of the circuit breaker 7 is connected to the drive system 1 through three power lines, and the other end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com