Magnetic molecular targeted ultrasound contrast agent microsphere and preparation method thereof

An ultrasonic contrast agent and microsphere technology, applied in the direction of echo/ultrasonic imaging agent, can solve the problems of unsatisfactory and insufficient imaging effect, and achieve the effect of less equipment investment, simple operation, and easy process amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

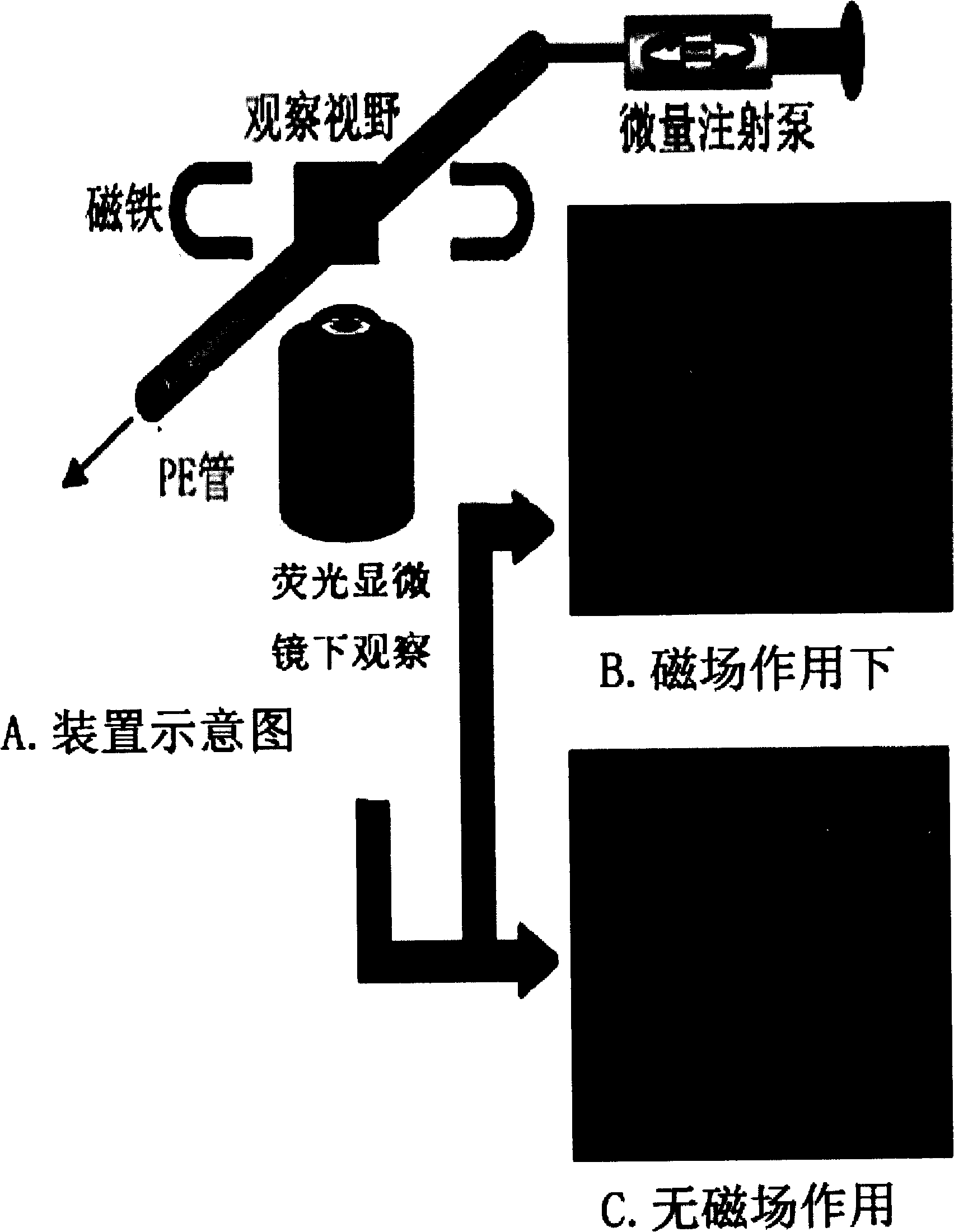

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Effect of Shear Rate on Microsphere Yield and Particle Size

[0044] Weigh phospholipids by 0.1% by weight, weigh polyethylene glycol (PEG) by 1% by weight, 0.01% by weight PEG polymerized phospholipids, 0.045% by weight biotinylated PEG polymerized phospholipids, and weigh 0.01% by weight phospholipid magnetic beads, Weigh the mixture of poloxamer at 0.03% by weight, add it to the water medium (distilled water) and mix it well under the condition of 50-80°C, inject perfluoropropane gas, and insert the dispersing cutter head of the high-speed liquid shearer into the liquid Next, the solution was subjected to high-speed shear dispersion at different rotational speeds, and the concentration and particle size data of the prepared microspheres are shown in Table 1.

[0045] Table 1 Effect of shear rate on microsphere concentration and particle size

[0046] Speed(r / min)

[0047] It can be seen from Table 1 that as the rotational speed of the dispersing...

Embodiment 2

[0048] Example 2: Effect of Adding Avidin and Biotinylated Monoclonal Antibody on Microsphere Size and Concentration

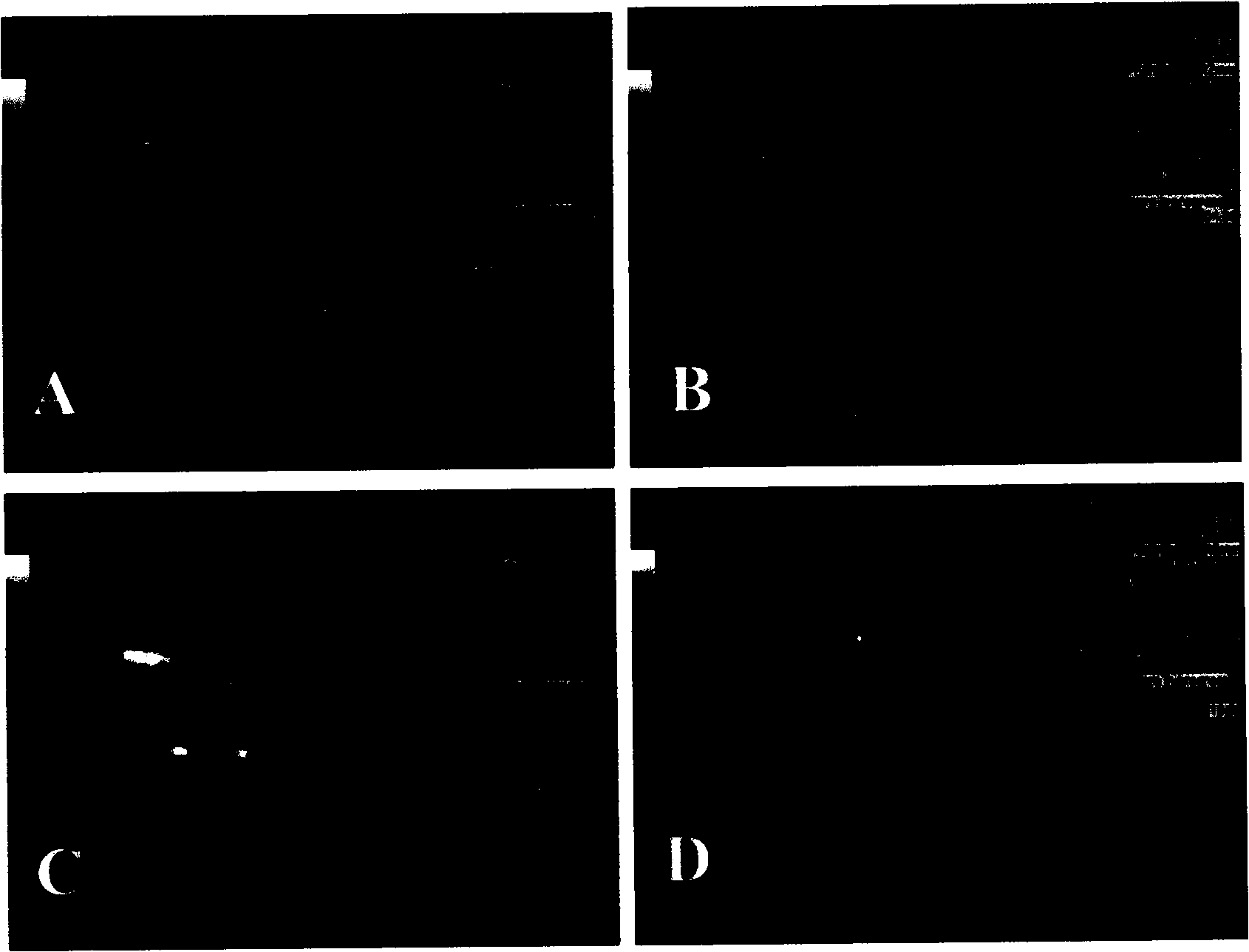

[0049] Weigh phospholipids by 0.1% by weight, weigh polyethylene glycol (PEG) by 1% by weight, 0.01% by weight PEG polymerized phospholipids, 0.045% by weight biotinylated PEG polymerized phospholipids, and weigh 0.01% by weight phospholipid magnetic beads, Weigh the mixture of poloxamer at 0.03% by weight, add it to the water medium (distilled water) and mix it well under the condition of 50-80°C, inject perfluoropropane gas, and insert the dispersing cutter head of the high-speed liquid shearer into the liquid Carry out high-speed shear dispersion (24000r / min) under the surface, make milky white contrast agent microsphere suspension liquid and pack in ampoule, observe under sampling microscope ( figure 1 A), use a Coulter counter to measure the concentration and particle size of the microspheres; after standing for 24 hours, discard the supernatant and add a...

Embodiment 3

[0053] Example 3: In vitro pressure resistance of ultrasound contrast agent microspheres of the present invention

[0054] Weigh phospholipids by 0.1% by weight, weigh polyethylene glycol (PEG) by 1% by weight, 0.01% by weight PEG polymerized phospholipids, 0.045% by weight biotinylated PEG polymerized phospholipids, and weigh 0.01% by weight phospholipid magnetic beads, Weigh the mixture of poloxamer at 0.03% by weight, add it to the water medium (distilled water) and mix it well under the condition of 50-80°C, inject perfluoropropane gas, and insert the dispersing cutter head of the high-speed liquid shearer into the liquid Perform high-speed shear dispersion (24000r / min) under the surface to prepare milky white contrast agent microsphere suspension and distribute it in ampoules; after standing for 24 hours, discard the supernatant and add an equal amount of distilled water to wash to remove unbound lipids 1. Purify 3 times to prepare biotin lipid microbubbles, add 0.005% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com