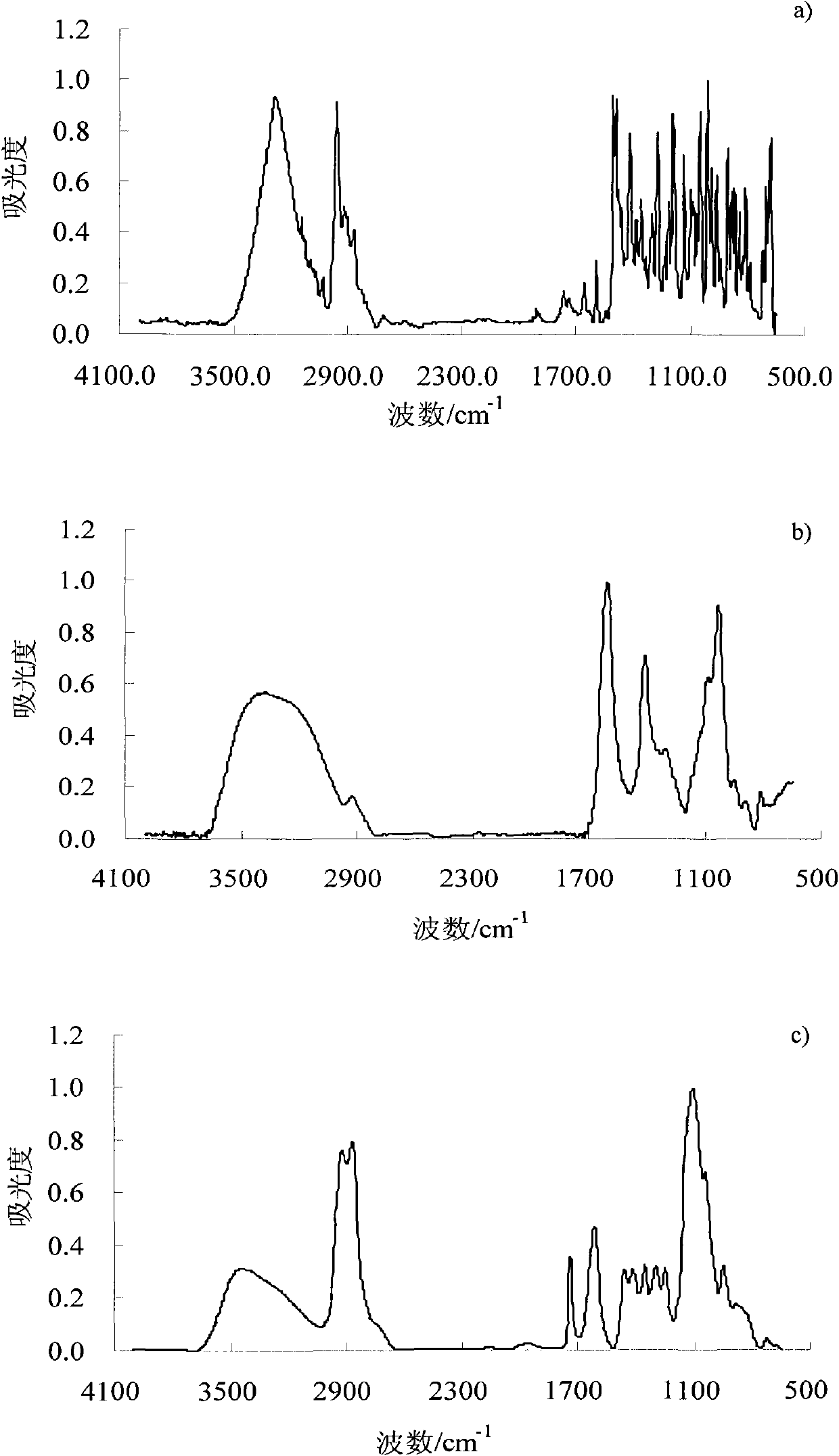

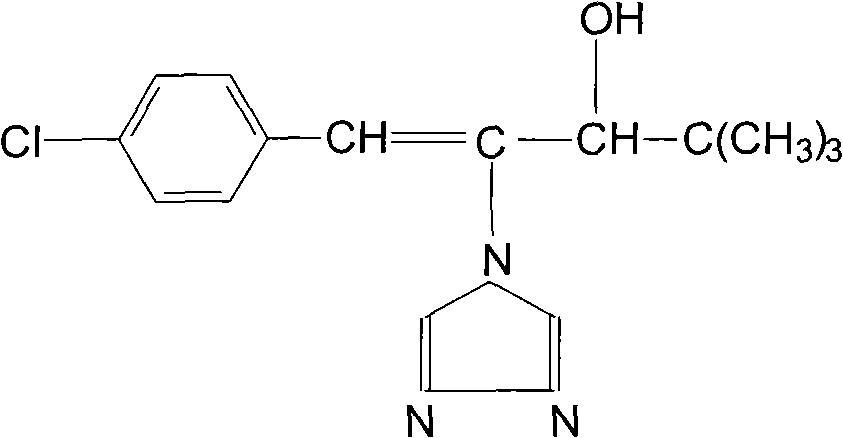

Uniconazole slow-release microcapsules and preparation method thereof

A technology of uniconazole and microcapsules, applied in the field of agriculture, can solve the problems of easy drift, low bioavailability, easy optical isomerization inactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

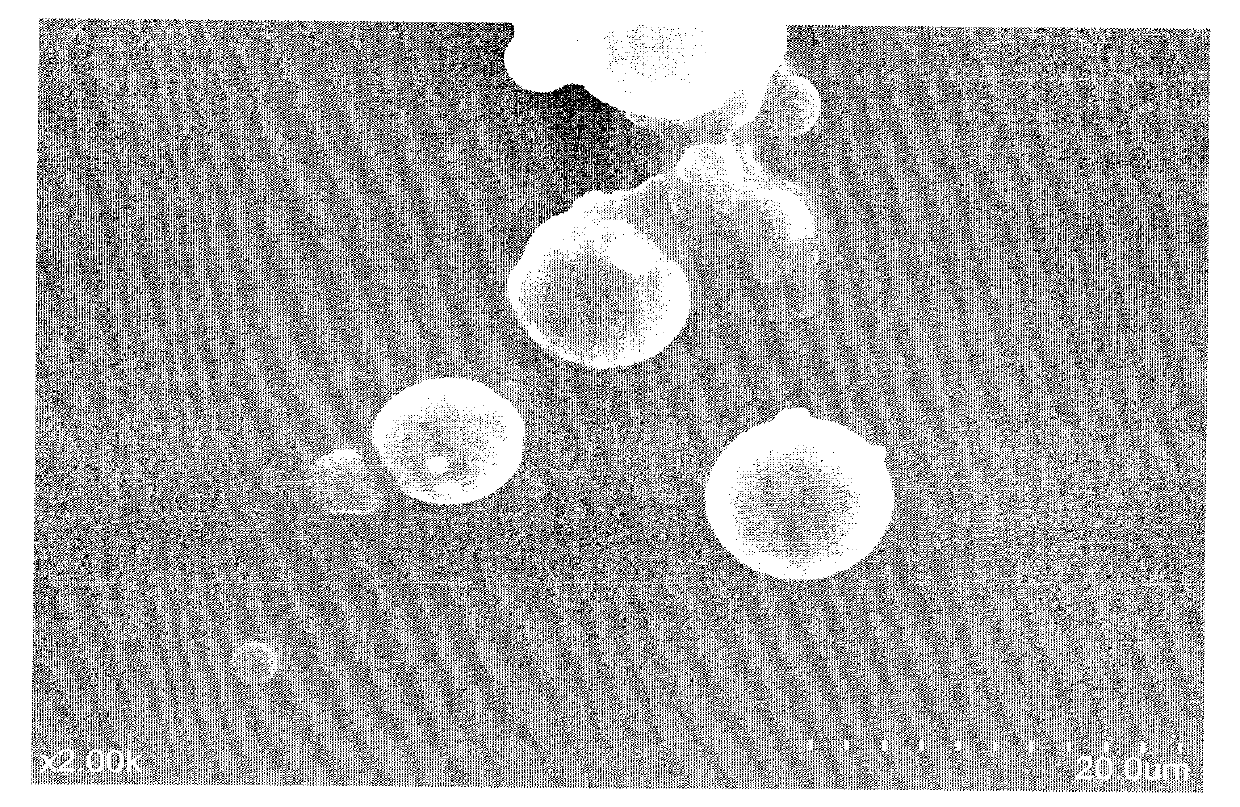

[0029] Example 1, Preparation of Uniconazole Sustained-release Microcapsules with Average Particle Size of 75 μm

[0030] The original drug selects the original drug of 97% uniconazole produced by Jiangsu Qizhou Green Chemical Co., Ltd. (the following examples are the same).

[0031] Weigh 0.5g of sodium alginate and dissolve it in 20mL of water, slowly add 1.0mL of sorbitan monooleate polyoxyethylene ether under stirring at 800rpm, continue stirring and emulsifying at the same rate for 10min; weigh 0.1g of uniconazole solution In 2.0mL acetone, slowly add 0.5mL tristyrylphenol polyoxyethylene polyoxypropylene ether under stirring at 1500rpm, stir and emulsify for 5min; slowly add uniconazole emulsion into the emulsified In the sodium alginate solution, continue to stir and emulsify for 30 minutes until the mixed solution is evenly dispersed; set the inlet temperature of the spray dryer to 150°C, and the outlet temperature to 95°C, and use the spray dryer to solidify and dry t...

Embodiment 2

[0037] Example 2, Preparation of Uniconazole Sustained-release Microcapsules with Average Particle Size of 20 μm

[0038]Weigh 2.0 g of chitosan and 1.0 g of gelatin and dissolve them in 100 mL of 2% acetic acid solution, slowly add 2 mL of sorbitan monolaurate into the above solution under stirring at 800 rpm, and continue stirring for 20 min. Then 1.0 mL of fatty alcohol polyoxyethylene ether was mixed with 2.0 mL of 7.5% uniconazole ethanol solution, and stirred and emulsified at 1000 rpm for 10 min. Then slowly add the uniconazole emulsion into the acetic acid solution of emulsified chitosan and gelatin under stirring at 1200 rpm, and continue stirring for 45 minutes until the mixture is evenly dispersed. Finally, the obtained mixed solution is solidified and dried in a spray dryer with an inlet temperature of 135° C. and an outlet temperature of 85° C., and the obtained powder is uniconazole sustained-release microcapsules.

[0039] The method for measuring the performan...

Embodiment 3

[0041] Example 3, Preparation of Uniconazole Sustained-release Microcapsules with Average Particle Size of 5 μm

[0042] Weigh 0.3g of sodium alginate and 0.15g of gelatin and dissolve them in 20mL of water, slowly add 1.0mL of nonylphenol polyoxyethylene ether into the above solution under stirring at 1000rpm, and continue stirring for 20min. Then 1.0 mL of polyoxyethylene polyoxypropylene ether of sorbitan was mixed with 2.0 mL of 6% uniconazole isopropanol solution, and stirred and emulsified at 1200 rpm for 8 min. Then slowly add the uniconazole emulsion into the emulsified sodium alginate and gelatin solution under stirring at 1800rpm, and continue stirring for 40 minutes until the mixture is uniformly dispersed. Finally, the obtained mixed solution is solidified and dried in a spray dryer with an inlet temperature of 145° C. and an outlet temperature of 90° C., and the obtained powder is uniconazole sustained-release microcapsules.

[0043] The method for measuring the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com