Functional smoke agent for hot fogging machine and preparation method thereof

A technology of smoke generator and fog machine, which is applied in the field of functionalized smoke generator for hot fog machines and its preparation, which can solve the problems of lack of control effect, easy fire, and decline of control effect, and achieve remarkable and effective control effect The effect of stabilizing the ingredients and improving the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

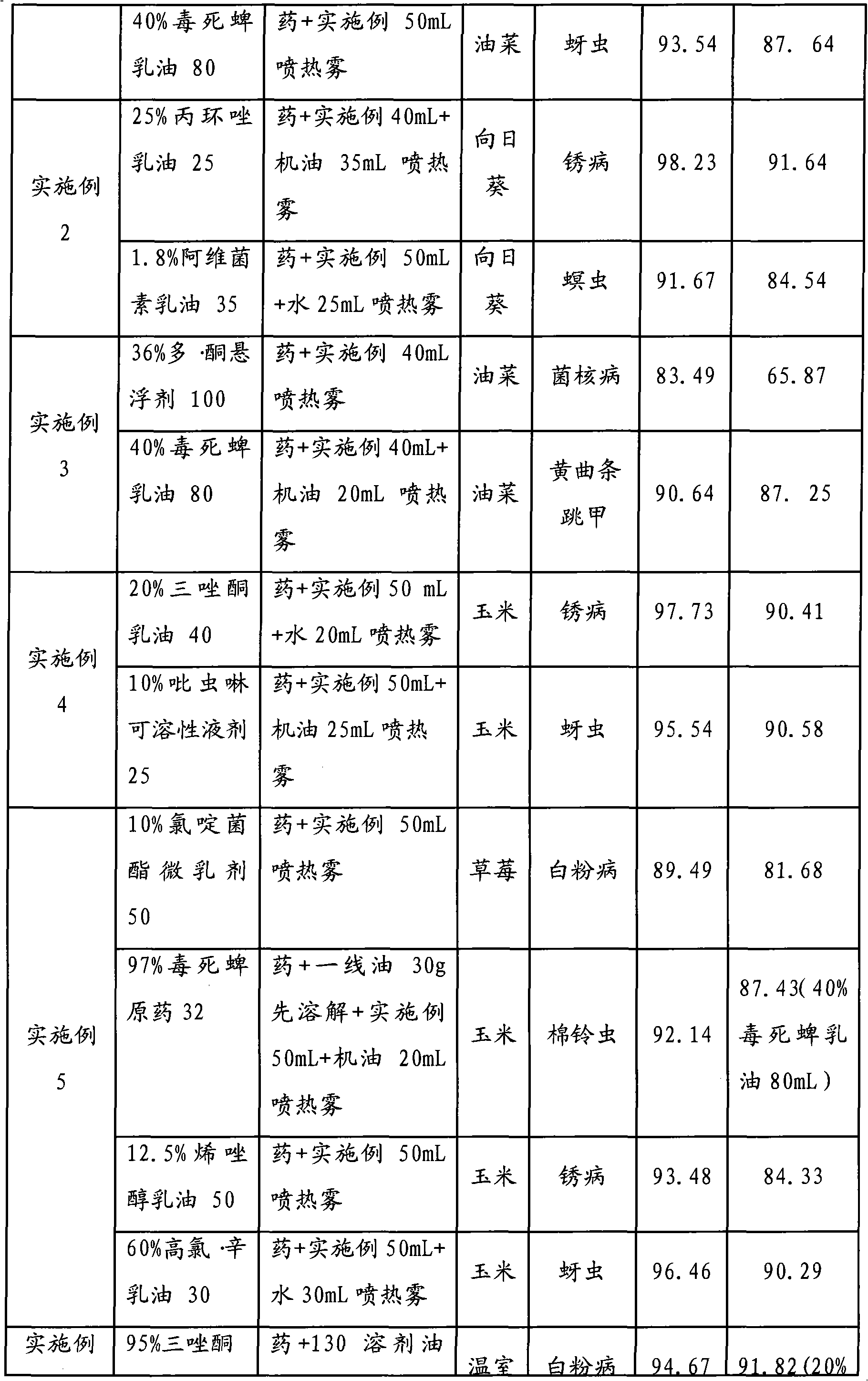

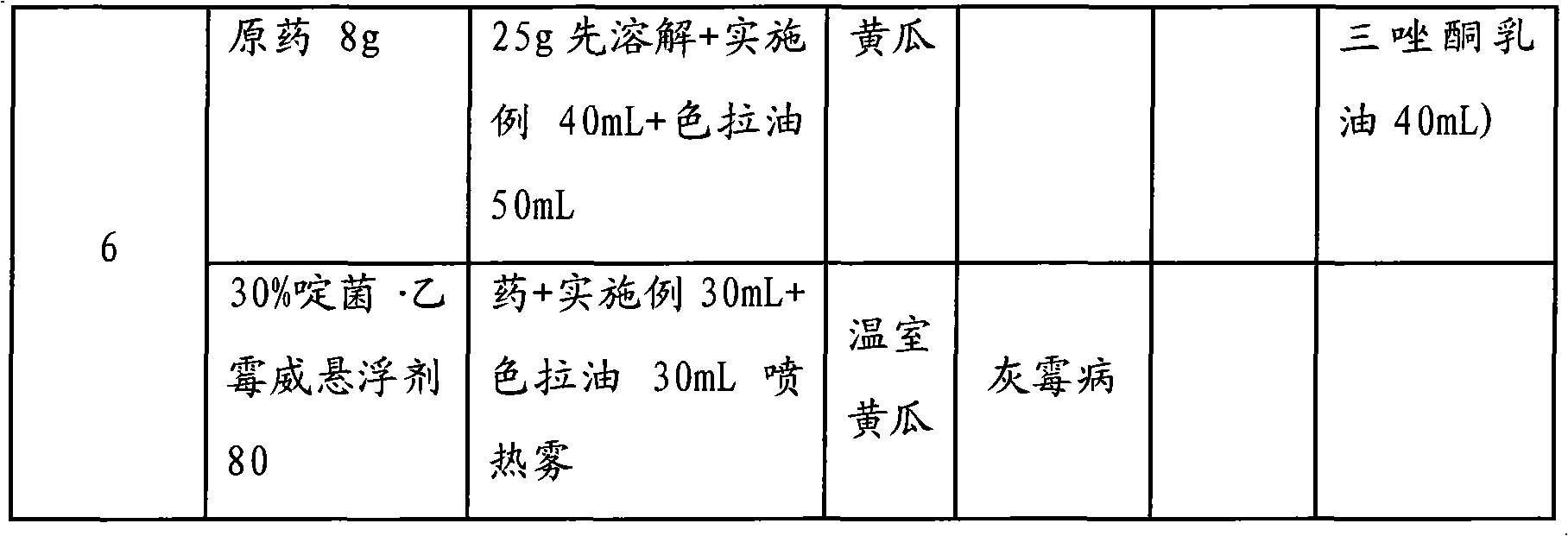

Examples

Embodiment 1

[0027] Raw material formula: by mass percentage:

[0028] Surfactant tributylphenol ethoxylate 5%

[0029] Surfactant Span 80 2%

[0030] Surfactant Farm Milk 500 5%

[0031] Hot fog density regulator urea 10%

[0032] Fire retardant ammonium polyphosphate 5%

[0033] Antifreeze glycol 6%

[0035] The rest is water.

[0036] Preparation:

[0037] First, water-soluble tributylphenol polyoxyethylene ether, Span 80, Nongru 500, urea, ethylene glycol, and octanol are dissolved in water to form a water phase under stirring, and then water-insoluble triphenyl phosphate is introduced into the water phase to increase Dissolve, continue to stir to form the water phase, filter to remove a small amount of residue, and obtain the finished product.

[0038] This embodiment is suitable for the vast majority of pesticides currently on the market. Commercially available liquid pesticides (or the solution of a suitable solvent for the original pesticide) ca...

Embodiment 2

[0040] Raw material formula: by mass percentage

[0041] Surfactant EO-PO block copolymer 6%;

[0042] Surfactant Nongru No. 500 3%,

[0043] Surfactant OP-10 3%

[0044] Hot fog density regulator urea 10%

[0045] Flame Resistant Triphenyl Phosphate 5%

[0046] Antifreeze glycol 6%

[0048] The rest is water.

[0049] The preparation method is the same as in Example 1.

[0050] This embodiment is suitable for most of the pesticides currently on the market. You can take the commercially available liquid pesticide (or the solution of the appropriate solvent for the original pesticide) per mu according to the dosage in the instructions, and then add the fuming agent of this example to 100-150mL After mixing evenly, you can use a hot fog machine to spray; you can also add 30-50mL of the smoke agent in this example according to the prescribed amount, and then use diesel oil or vegetable oil or water to make up to 100-150mL, and then use a hot fog...

Embodiment 3

[0052] Raw material formula: by mass percentage

[0053] Surfactant EO-PO block copolymer 15%;

[0054] Hot mist density regulator p-dichlorobenzene (dissolved with a small amount of first-line oil) 10%

[0055] Fire retardant water soluble ammonium polyphosphate 5%

[0056] Antifreeze urea 5%

[0057] Antifoaming agent polydimethylsiloxane 0.3%

[0058] The rest is water.

[0059] Preparation method: First, dissolve water-soluble EO-PO block copolymer, ammonium polyphosphate, urea, and polydimethylsiloxane in water under stirring to form a water phase, and then introduce water-insoluble p-dichlorobenzene first-line oil solution into Solubilize the water phase, continue to stir to form the water phase, filter to remove a small amount of residue, and obtain the finished product.

[0060] This embodiment is suitable for most of the liquid pesticides currently on the market, especially for liquid pesticide preparations prepared with organic solvents such as benzene solvents,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com