Method for high-efficiently processing asphalt fumes

A kind of asphalt fume, high-efficiency technology, applied in the direction of combustion method, lighting and heating equipment, combined combustion mitigation, etc., can solve the problems of incomplete governance, high operation cost, and no application, etc., to achieve low investment cost and low operation cost , good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

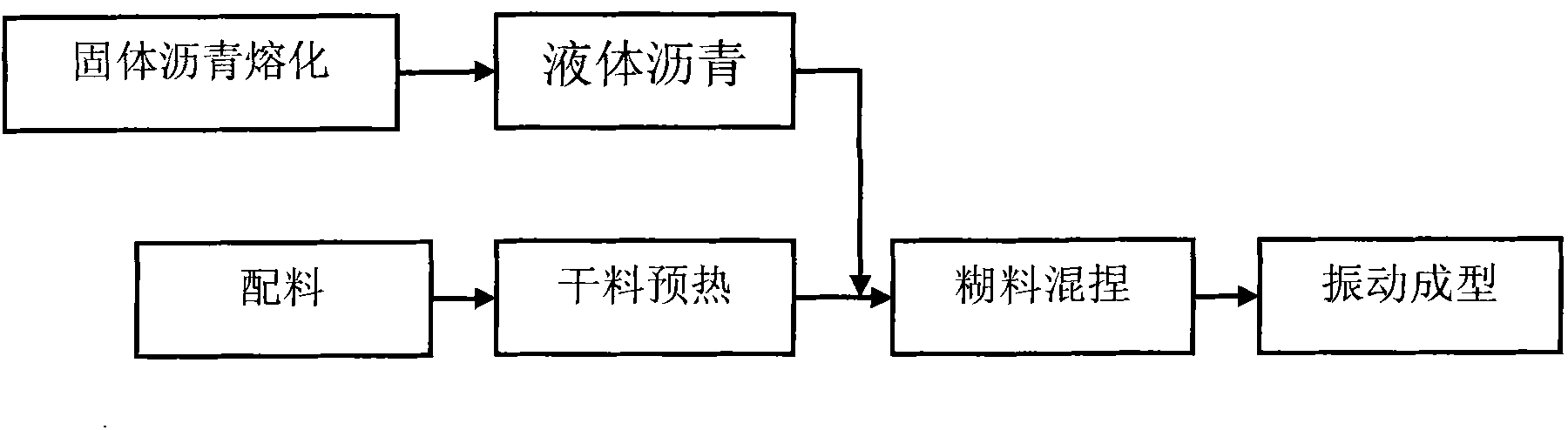

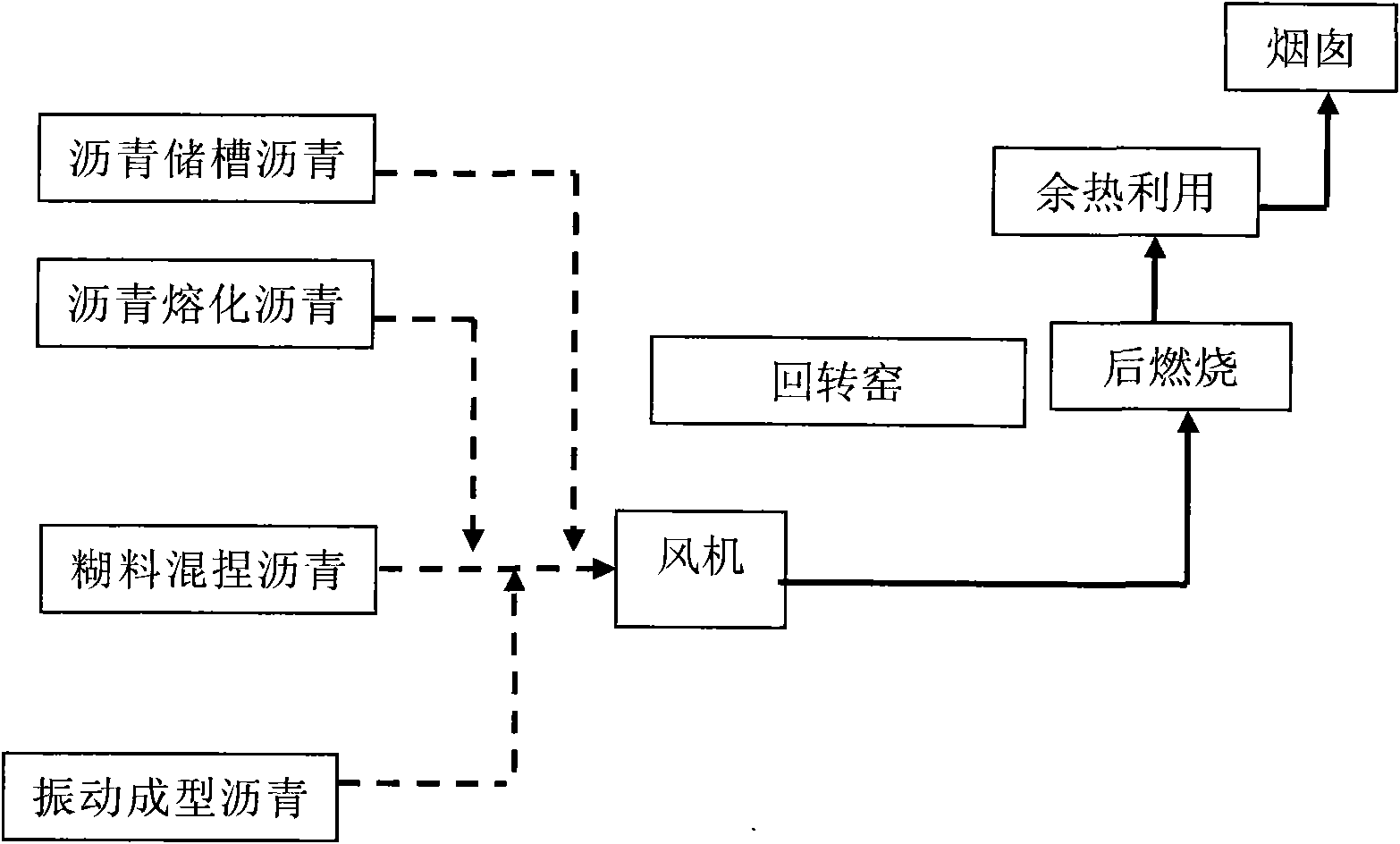

[0017] First collect the asphalt flue gas produced by the asphalt melting process, asphalt storage tank, batching kneading, cooling material, and vibration molding, and use a high-power induced draft fan to directly send it to the rear combustion chamber of the rear rotary kiln for waste heat incineration. During the initial design, the positions of the raw anode manufacturing workshop, asphalt melting workshop, and combustion chamber after petroleum coke calcination are optimized, so that the asphalt fume generated by green anode manufacturing and asphalt melting can be introduced into the combustion chamber more easily and conveniently. Save investment and reduce costs. Use the calcined flue gas with a temperature of 1100-1200°C in the combustion chamber of the rotary kiln to pass the asphalt flue gas through the combustion chamber of the rotary kiln. The tar and polycyclic aromatic hydrocarbons in the asphalt flue gas are decomposed and burned to effectively remove benzopyre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com